Material carrying operating vehicle

A technology for operating vehicles and materials, which is applied to motor vehicles, tracked vehicles, transportation and packaging, etc., and can solve problems such as reduced manpower operations and insufficient handling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

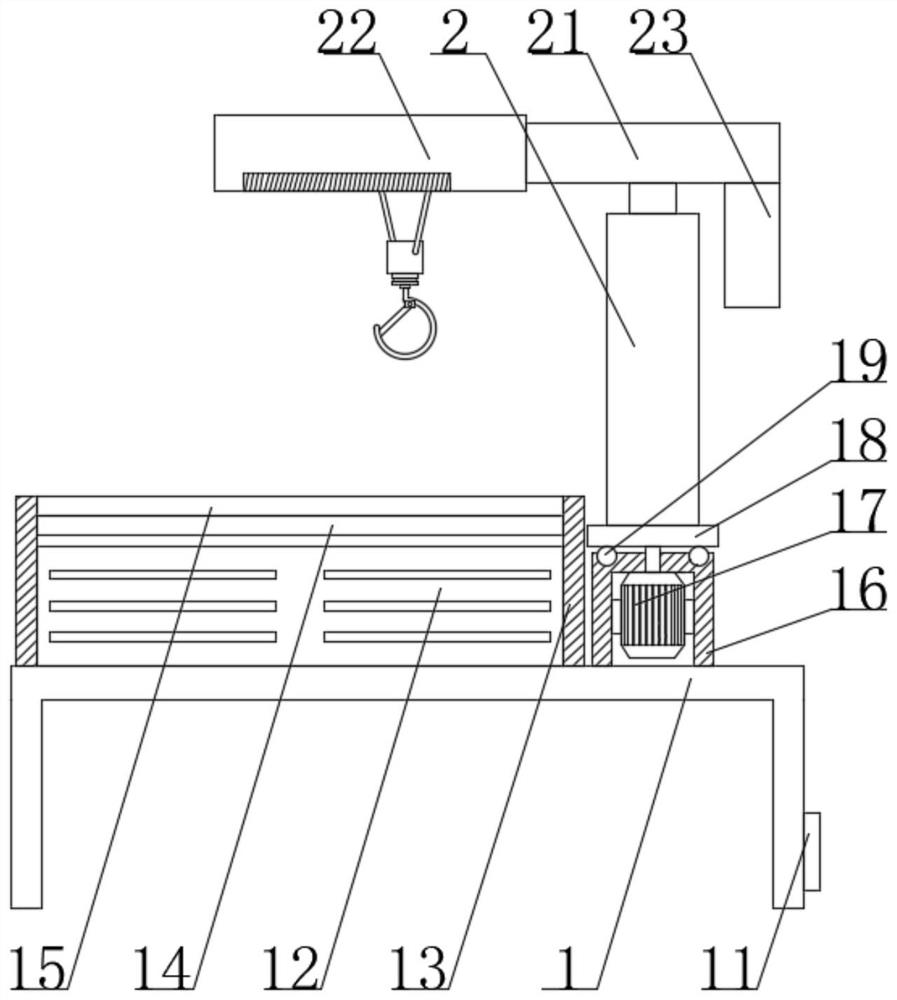

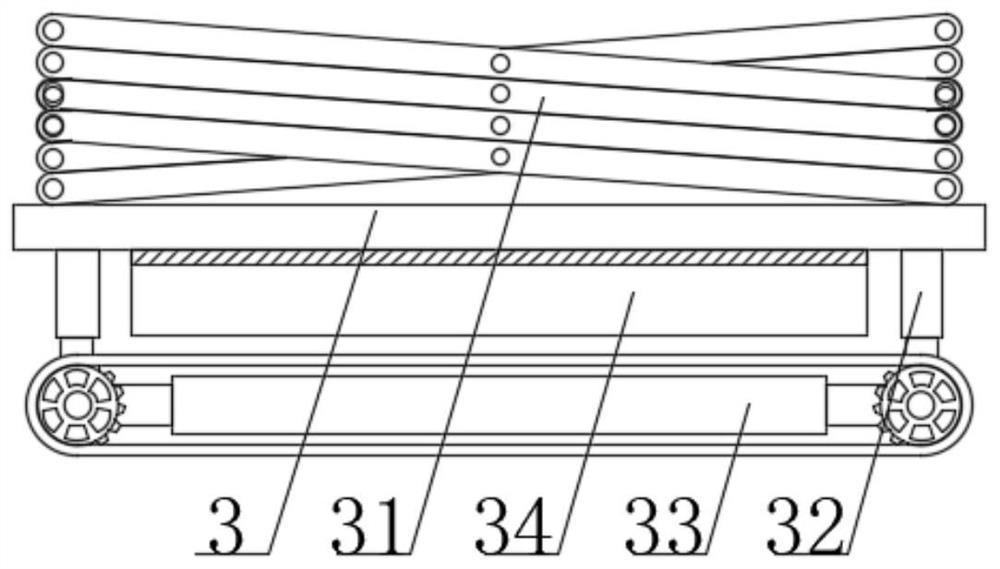

[0025] see figure 2 , the present invention provides a technical solution: a material handling operation vehicle, including a support platform 1, the support platform 1 has a U-shaped structure, and the support platform 1 of the U-shaped structure can effectively improve the support strength of the structure, which is convenient for users to install accessories at the bottom. Components and accessory components are components that users need to connect according to actual needs. The middle part of one side of the support table 1 near the bottom is fixedly connected with a controller 11 by screws. The controller 11 can effectively facilitate the user's manipulation and use. The support A storage battery 12 is fixedly connected to one end of the upper surface of the platform 1 by bolts, and the battery 12 can facilitate power supply. The periphery of the storage battery 12 is sleeved with a bearing platform 13, and the bottom end of the bearing platform 13 is fixedly connected t...

Embodiment 2

[0027] see Figure 1-5, the present invention provides a technical solution: a material handling operation vehicle, including a support platform 1, the support platform 1 has a U-shaped structure, and the support platform 1 of the U-shaped structure can effectively improve the support strength of the structure, which is convenient for users to install accessories at the bottom. Components and accessory components are components that users need to connect according to actual needs. The middle part of one side of the support table 1 near the bottom is fixedly connected with a controller 11 by screws. The controller 11 can effectively facilitate the user's manipulation and use. The support A storage battery 12 is fixedly connected to one end of the upper surface of the platform 1 by bolts, and the battery 12 can facilitate power supply. The periphery of the storage battery 12 is sleeved with a bearing platform 13, and the bottom end of the bearing platform 13 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com