Mixed reaction kettle for processing pressure-sensitive collagen glue solution

A technology of pressure-sensitive collagen and reactors, which is applied in the direction of chemical/physical/physicochemical fixed reactors, etc., and can solve the problems of waste of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

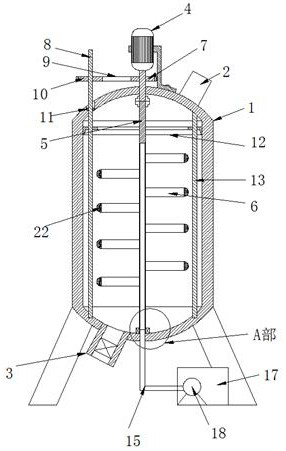

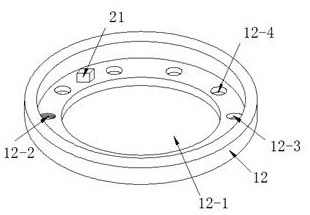

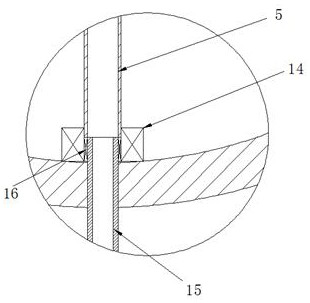

[0021] Such as Figure 1-Figure 4 As shown, this specific embodiment adopts the following technical scheme: it includes a reactor body 1, a material inlet 2, a material outlet 3, a No. 1 drive motor 4, a rotating shaft 5, and a stirring rod 6; the top wall of the reactor body 1 runs through Connected to the feed port 2, the bottom wall of the reactor body 1 is connected with the discharge port 3, the No. 1 drive motor 4 is fixed on the top wall of the reactor body 1 by a motor bracket, and its output shaft passes through the reactor body 1 After the top wall of the reactor body, it is connected with the rotating shaft 5 by a coupling, and the bottom end of the rotating shaft 5 is supported and rotated on the inner bottom wall of the reactor body 1 by means of the No. 2 bearing 14, and several stirring rods 6 are fixed on the outer wall of the rotating shaft 5 , it also includes linkage mechanism, screw mandrel 8, No. 1 bearing 11, scraper 12, guide rod 13; above-mentioned link...

specific Embodiment approach 2

[0030] see Figure 5The difference between this specific embodiment and the first specific embodiment is that the linkage mechanism is replaced by the No. The upper end of the rod 8 is connected with the output shaft of the second drive motor 20 by a coupling. The rest of the structures and connections are the same as in the first embodiment. When the embodiment is working, the rotation of the rotating shaft 5 and the rotation of the screw mandrel 8 are driven separately, and whether to use the scraper 12 is selected according to the needs, that is, when the stirring process , No. 2 drive motor 20 may not be enabled, that is, the scraper 12 does not work, it is placed on the inner top of the reactor body 1, and it is only used at the end of discharge or in the cleaning state, so as to prevent the paint from adhering to the scraper 12 superior,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com