Aerosol generating method

A production method and aerosol generation technology, applied in the direction of tobacco, etc., can solve the problems of limited application range, suction obstruction, low sensor sensitivity, etc., and achieve the effect of expanding the use range, convenient and flexible use, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides a method for generating aerosol by using an aerosol generating device.

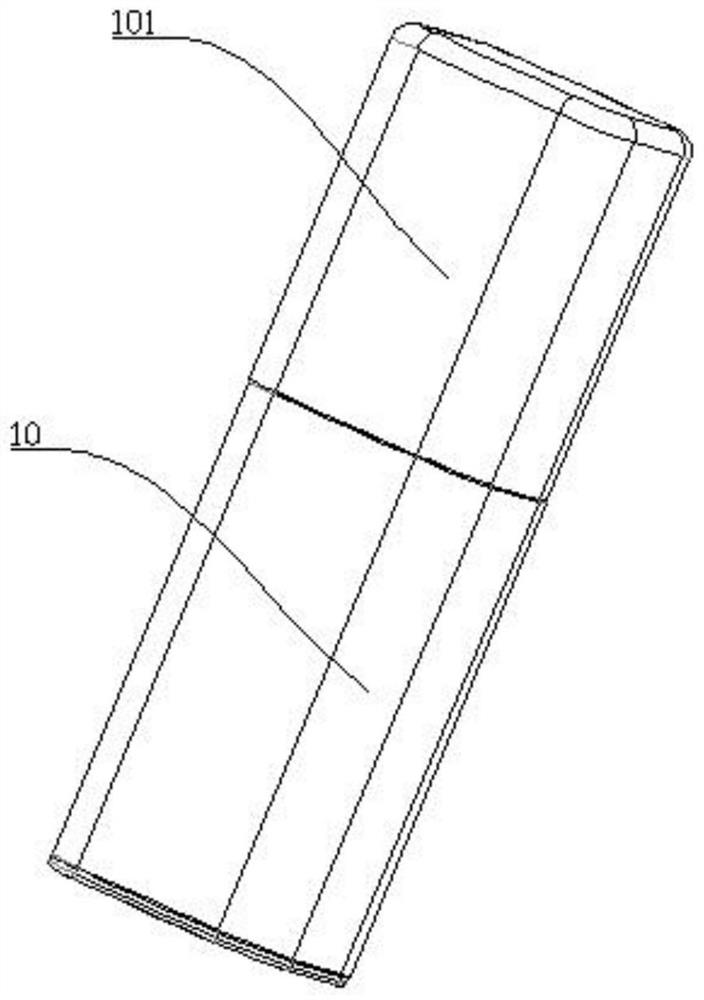

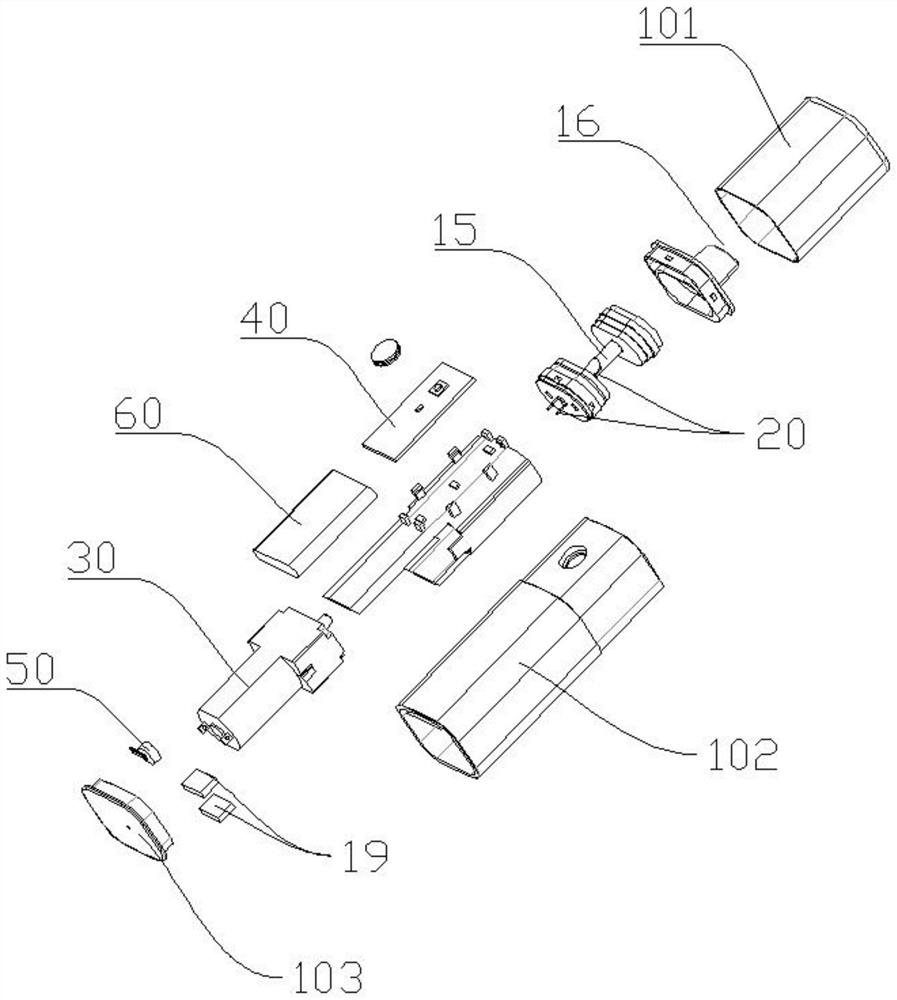

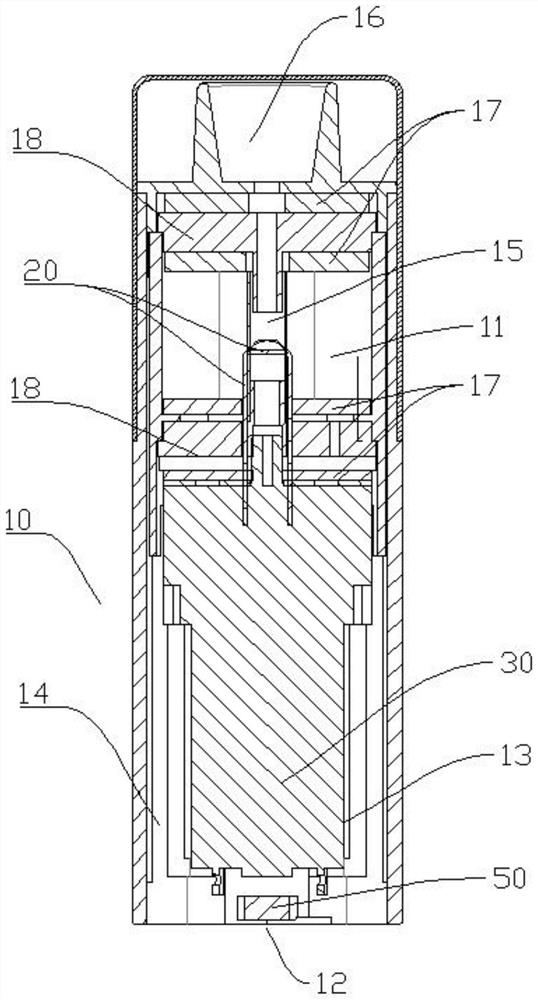

[0050] Such as Figure 1~4 Shown is the aerosol generating device in this embodiment, including a housing 10 , a heating device 20 , an air supply device 30 , a first control device 40 and a second control device 50 . The casing 10 includes a middle shell 102 and a lower cover 103 arranged at the bottom of the middle shell 102 for sealing the middle shell 102; a cavity 11 for accommodating the aerosol generating matrix is formed in the middle shell 102. In this embodiment, the middle shell 102 is provided with sealing blocks 18 arranged at intervals along the gas flow direction, and the sealing blocks 18 are in contact with the inner wall of the middle shell 102 to seal, so that a cavity 11 is formed between the sealing block 18 and the middle shell 102. In this embodiment, the sealing blocks 18 are Silicone material. Both the bottom and the top of the sealing block 18 ...

Embodiment 2

[0069] This embodiment provides a method for producing an aerosol using an aerosol generating device, the aerosol generating device in this embodiment is as Figure 5 As shown, the aerosol generating device in this embodiment is based on the addition of a gas purification device 70 on the basis of Embodiment 1, and the gas purification device 70 is arranged in the middle shell 102 for purifying the gas entering the middle shell 102 . In this embodiment, the gas purification device 70 is arranged between the cavity 11 and the gas supply device 30, the gas inlet end of the gas purification device 70 communicates with the first airflow passage 13 and the second airflow passage 14 respectively, and the gas outlet connects with the mixing The airflow channel 15 is connected, so that the gas coming out of the first airflow channel 13 and the second airflow channel 14 can be purified to ensure a more hygienic aerosol. In practical applications, the purification device 70 can also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com