High-voltage direct-current power supply

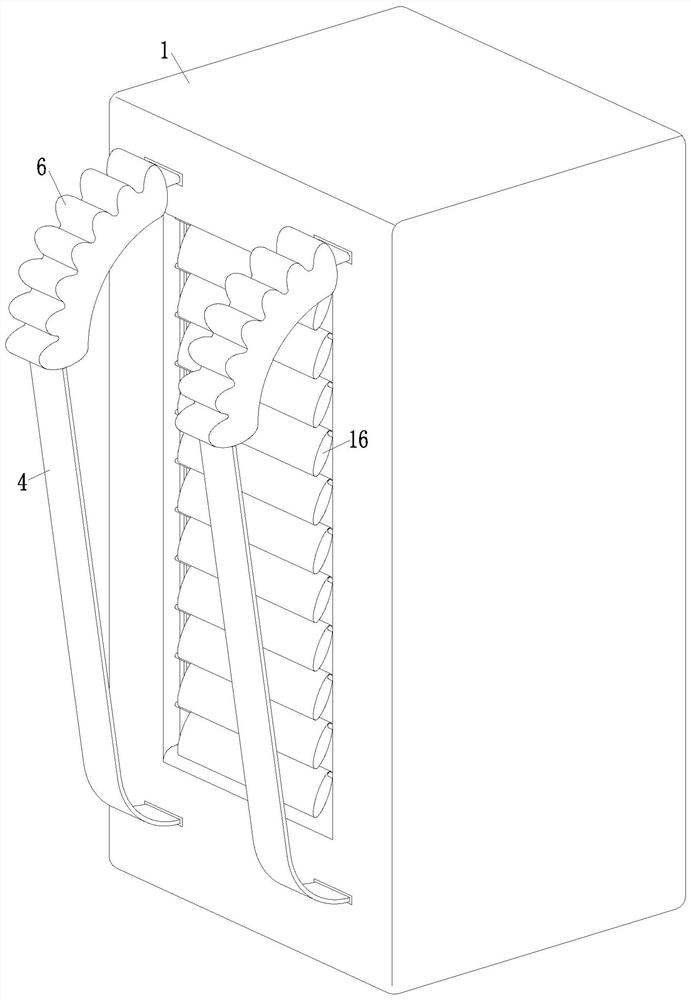

A high-voltage DC power supply, No. 1 technology, applied in electrical components, substation/switch layout details, anti-seismic equipment, etc., can solve the problems of high-voltage DC power supply electrical components shaking, time-consuming and laborious, affecting the service life of high-voltage DC power supplies, etc. Stability, improve service life, ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

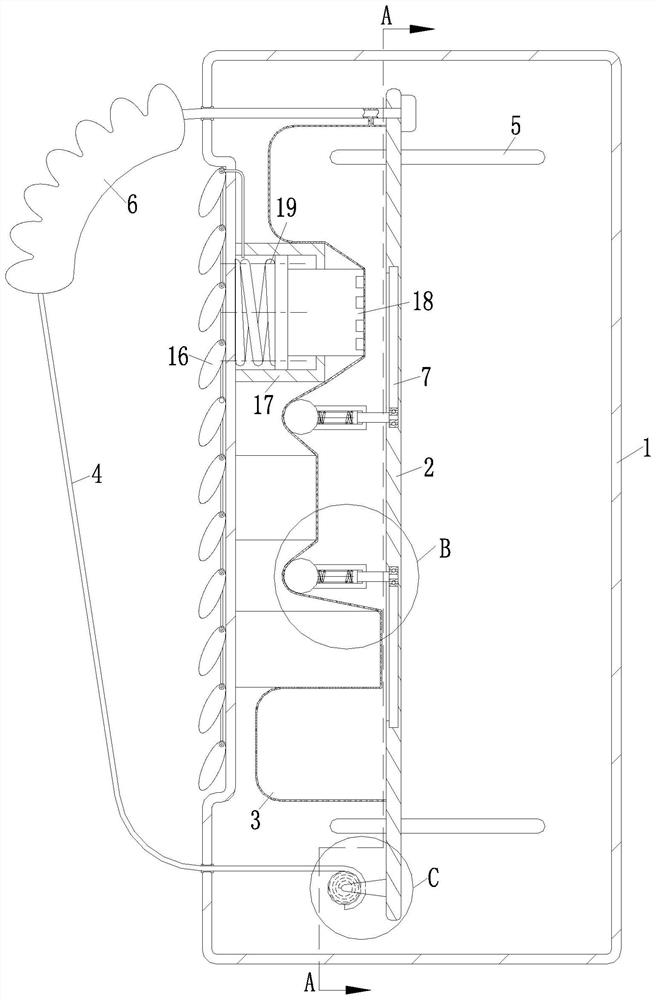

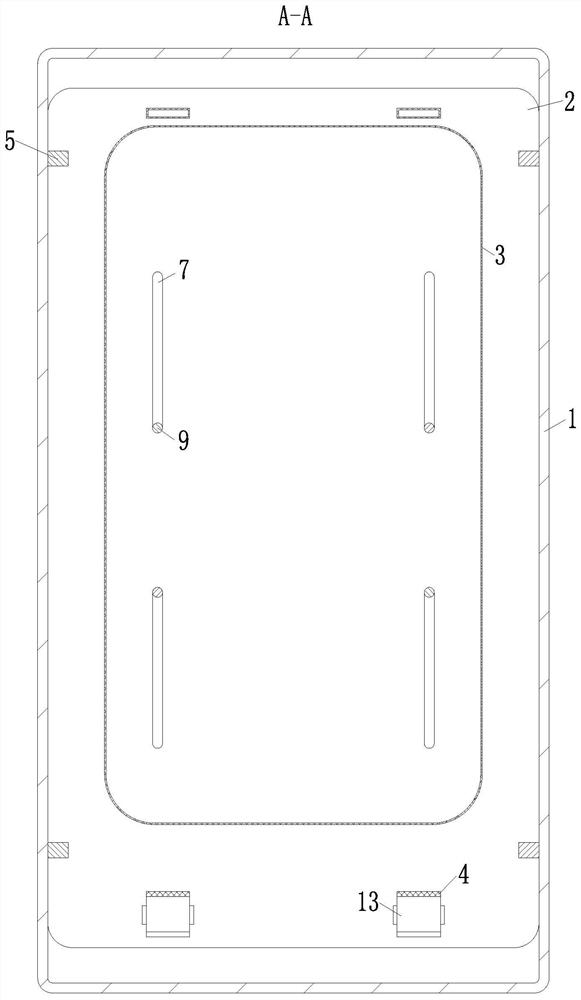

[0028] As an embodiment of the present invention, the lower part of the side of the side plate 2 is fixedly connected with two pulleys 13, each of the pulleys 13 is provided with a coil spring 14 inside, and the other of the two straps 4 One end respectively passes through the lower rectangular hole on the side of the box body 1 and is fixedly connected to the pulley 13; during operation, because the No. 1 air bag 3 is limited in restoring its original shape under the action of the spring force, the side plate 2 cannot retract the strap 4 into the box The inside of the body 1 affects the appearance of the high-voltage DC power supply; therefore, when the staff of the present invention stops carrying the high-voltage DC power supply, the coil spring 14 inside the pulley 13 will drive the pulley 13 to rotate, because the other end of the strap 4 is fixedly connected to the pulley 13 , so that the pulley 13 rolls up the strap 4, thereby retracting the extra strap 4 outside the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com