Tobacco consumption control system and method

A technology of control system and control method, which is applied in the field of cigarette production, can solve problems that cannot be found out in time, affect the silk yield, and data monitoring, and achieve the effects of improving scientificity and effectiveness, reducing tobacco leaf consumption, and improving the level of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

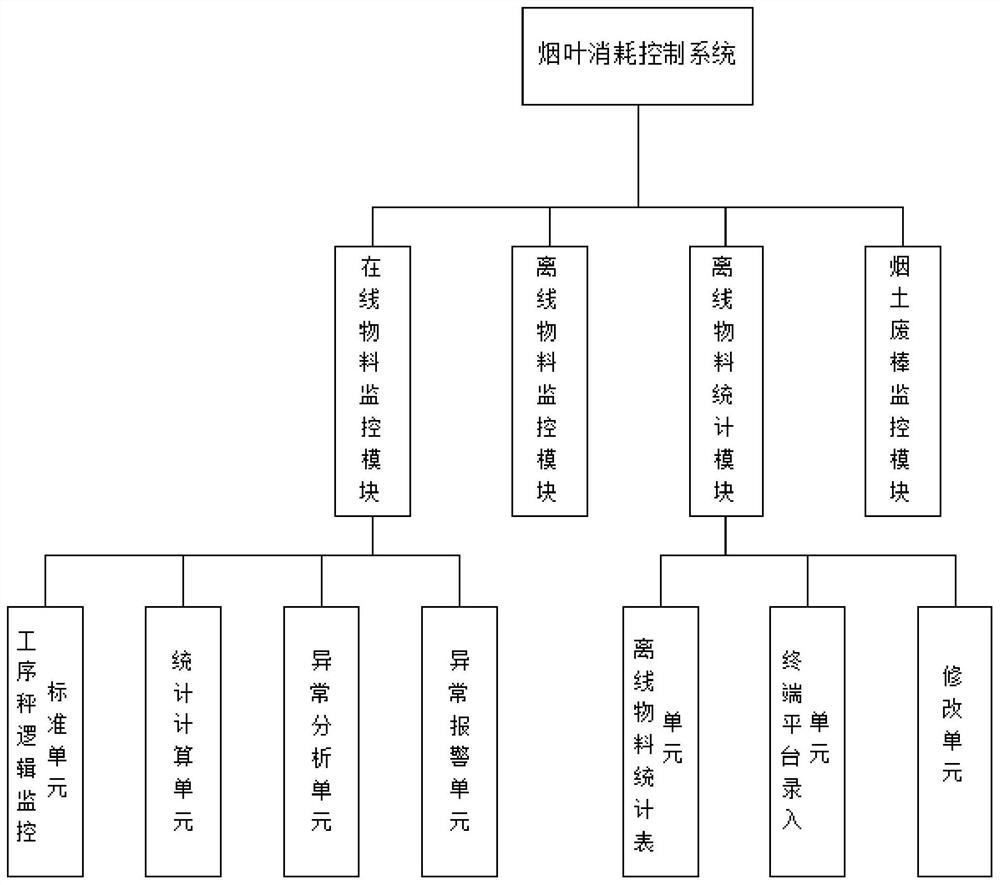

[0046] refer to figure 1 , the tobacco leaf consumption control system, including the database and the built-in:

[0047] The online material monitoring module, based on the input-output logic balance relationship between each process, sets the silk yield rate judgment standard interval, establishes process logic silk yield monitoring, and adopts batch-by-batch tracking and batch-by-batch analysis methods to improve the level of online material monitoring accuracy;

[0048] The offline material monitoring module adopts a multi-level and stepped monitoring method to classify the material consumption points according to the material stockpile in the production process, the frequency of abnormal occurrences, and the difficulty of control, and to control and monitor the materials by classification. Provide data basis for abnormal silk rate;

[0049] Offline material statistics module, which uses the terminal platform input method for offline material statistics;

[0050] Tobacc...

Embodiment 2

[0058] Tobacco leaf consumption control method, this method is applied to the tobacco leaf consumption control system of embodiment 1, and it comprises the following steps:

[0059] Step 1, build MSSQL database and set up data modules;

[0060] Step 2, write the relevant programs and interfaces of each data module;

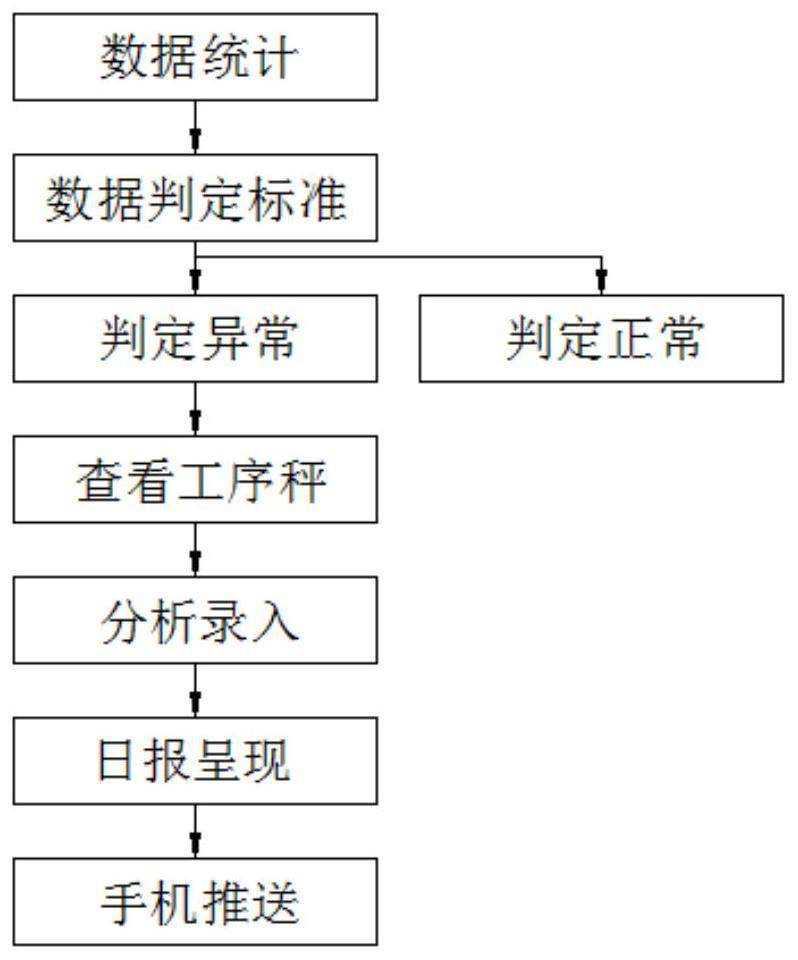

[0061] Step 3: Establish the logical monitoring standard of the process scale. In order to ensure the accuracy of the measurement, the measurement management system is revised, and the statistical calculation, abnormal analysis and alarm procedures are compiled. After each batch of production is completed, the system automatically performs statistics and judgments. staff to monitor and analyze;

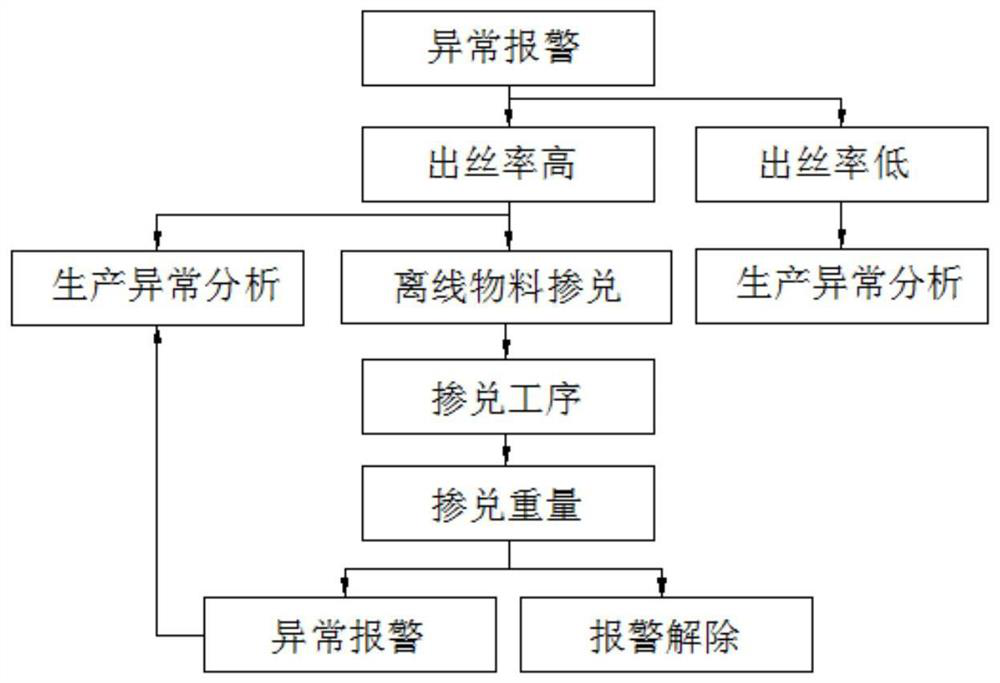

[0062] Step 4: Classify material consumption points according to the amount of material stock in the production process, the frequency of abnormal occurrences, and the difficulty of control, and carry out classified control and monitoring of materials, focusing on monito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com