Rocket turbopump floating ring seal testing testbed

A rocket turbine and sealing test technology, which is applied to rocket engine devices, pump control, non-variable pumps, etc., can solve the problems of flow-induced vibration instability, increased rotor vibration, low stability and reliability of rocket engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

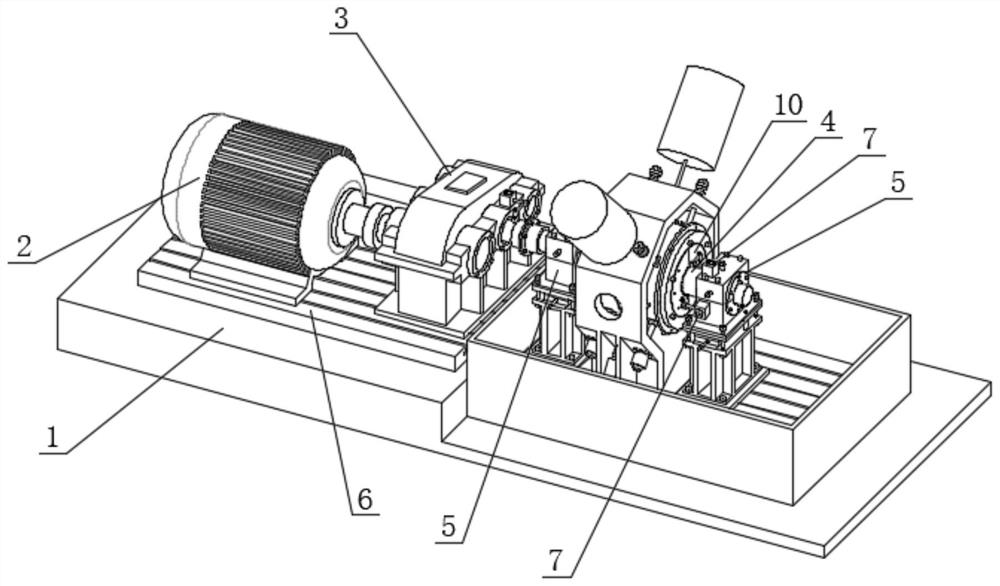

[0023] Specific implementation one: as Figures 1 to 4 As shown, the rocket turbo pump floating ring seal test bench of this embodiment includes a test base platform 1, a servo motor 2, a variable speed gearbox 3, a rotor 4, a test bench body, a T-slot guide 6, two bearing seats 5, Two positioning rings 13 and a plurality of eddy current displacement sensors 7; two T-slot guide rails 6 are arranged in sequence along the length direction of the test foundation platform 1, and the servo motor 2 and the variable speed gearbox 3 are arranged on the T-slot guide rail 6 in sequence, The rotor 4 is installed on the T-slot guide rail 6 through two bearing seats 5, and the output shaft of the servo motor 2 is connected with the rotor 4 through the transmission gearbox 3 and the coupling; the test bench body includes a front cavity 8 and a middle cavity 9. , the rear cavity 10 and two cavity labyrinth seals, both ends of the test bench body are provided with a positioning ring 13 and a ...

specific Embodiment approach 2

[0024] Specific implementation two: as figure 1 and image 3 As shown, in this embodiment, the front cavity 8 , the middle cavity 9 and the rear cavity 10 are fixedly connected together by a plurality of through bolts, and the two adjacent cavities are sealed by a sealing end face gasket.

[0025] In this way, the sealing between the two adjacent cavities is sealed by the sealing end face gasket, and the sealing between the front cavity 8, the middle cavity 9 and the rear cavity 10 is realized. At the same time, the front cavity 8 and the middle cavity 9 are sealed. The detachable connection with the rear cavity 10 realizes the installation and removal of the floating ring.

[0026] Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific implementation three: as figure 1 and figure 2 As shown, the T-slot guide 6 in this embodiment is composed of a first T-slot guide and a second T-slot guide. The first T-slot guide and the second T-slot guide are machined with a plurality of T-slots along their lengths. The groove, the servo motor 2 and the gear box 3 are installed on the upper end surface of the first T-slot guide rail, and the rotor 4, the test bench body and the two bearing seats 5 are installed on the upper end surface of the second T-slot guide rail.

[0028] This design facilitates adjusting the position of the servo motor 2 and the transmission gearbox 3 on the first T-slot guide rail, and facilitates adjusting the position of the rotor 4, the test bench body and the two bearing seats 5 on the second T-slot guide rail.

[0029] Other compositions and connection relationships are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com