Deslagging automatic water drainer for negative-pressure gas pipeline

An automatic water release and gas pipeline technology, which is applied in the directions of drainage, gas discharge, chemical instruments and methods, etc., can solve the problems of slow rise of water level, sedimentation of drilling slag, and inability to work normally, and achieves powerful and accurate opening and closing. , the effect of rapid action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

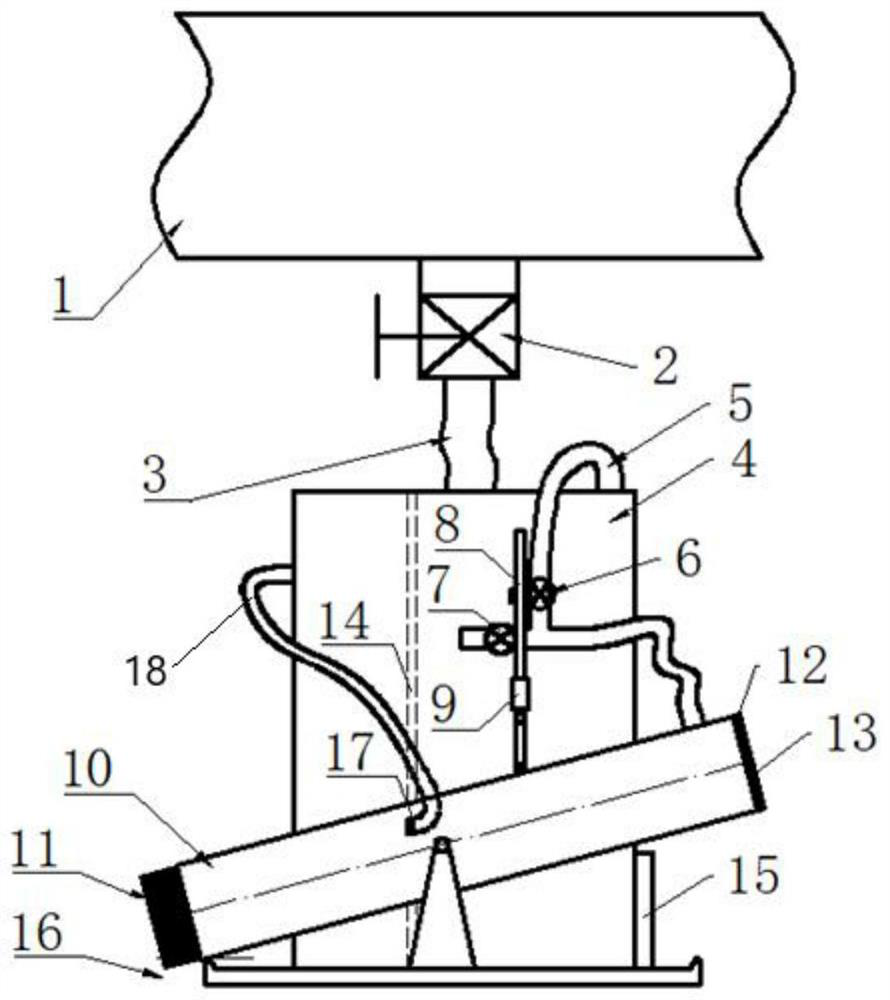

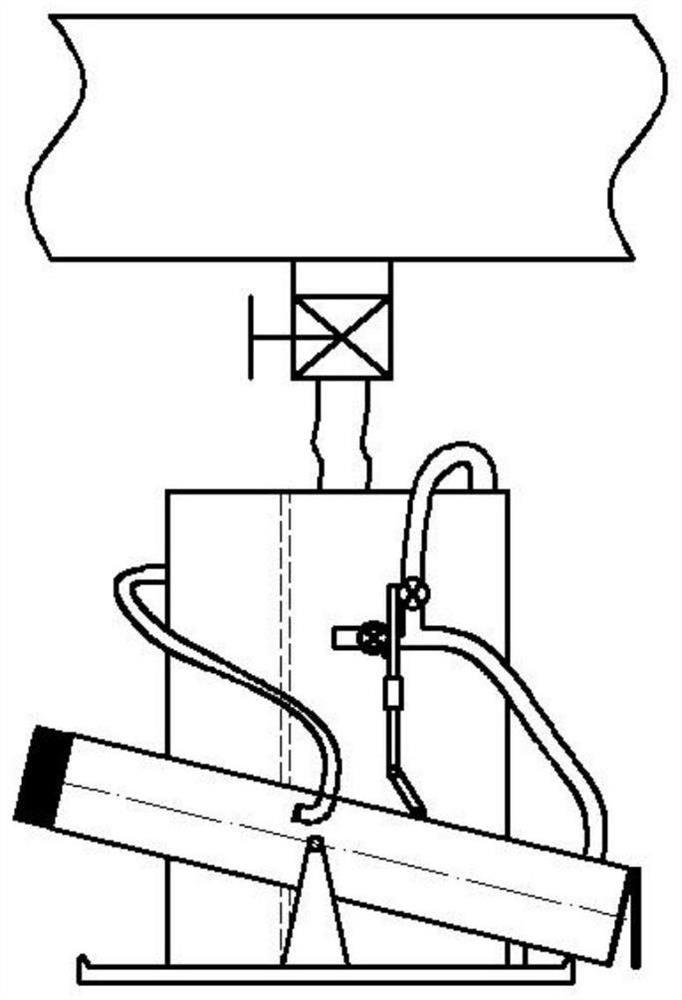

[0022] join figure 1 , figure 2 , a negative pressure gas pipeline slag removal automatic water drainer, comprising a base 16, water and sediment bucket 4, water tank 10 for draining.

[0023] Said accumulated water discharge bucket 10 is provided with an inclination, a counterweight 11 is arranged at the sealing end of said accumulated water discharge bucket 10, and a movable cover 13 is arranged at the open end of the accumulated water discharge bucket 10, and the upper end of said movable cover 13 is in contact with the accumulated water. The open end of water bucket 10 is hinged, and the lower end of movable cover plate 13 is free end, and described movable cover plate 13 is provided with sealing ring 12, is used for sealing the open end of accumulated water water bucket 10. The middle and lower part of the accumulated water bucket 10 is hingedly supported by the support, and the accumulated water sediment bucket 4 and the support are all installed on the base. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com