Method for manufacturing detachable toilet hanging mold support tool

A production method and toilet technology, which are applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problems affecting the quality of concrete pouring and the deformation of corner components. , The problem of inconvenient setting of the corner components of the toilet hanging formwork, etc., achieves the effect of simple structure, convenient production and reduced engineering cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The manufacturing method of the detachable toilet hanging mold support tool of the present invention includes the following steps:

[0030] a. Make the supporting tool body of the bathroom hanging mold.

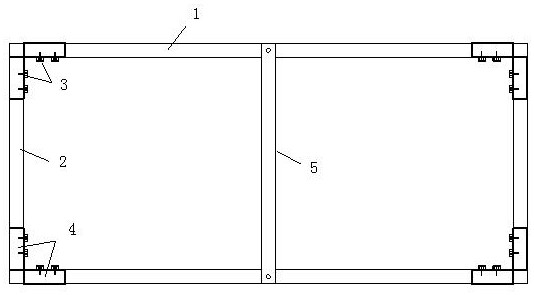

[0031] See now figure 1 , figure 1 It is a schematic diagram of a rectangular frame structure of a supporting tool according to an embodiment of the present invention. As shown in the figure, the main body of the toilet hanging mold support tool is a rectangular frame formed by solid welding of square steel pipes. The length and width of the rectangular frame are determined according to the structural size of the bathroom; the square steel pipe is 100*50*5mm.

[0032] b. Make four limit angles.

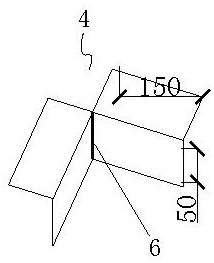

[0033] figure 2 It is a schematic diagram of the limiting angle steel structure of the supporting tool according to the embodiment of the present invention. Each limit angle steel includes two sections of angle steel. One side wide surface of the two sections of angle steel is erec...

Embodiment 2

[0038] The production and use requirements of the detachable toilet hanging mold support tool of the present invention:

[0039] The squareness requirements of the limit angle steel: the limit angle steel is formed by welding two angle steels, and the angle steel forming angle (90 degrees) must be met during the welding process. The purpose is to ensure the squareness of the bathroom concrete structure and the fastening between the angle steel and the square pipe. The bolts must ensure reliable connection, limit the deviation and looseness of the square pipe, and ensure smooth disassembly in the later stage.

[0040] The rigidity of the square steel pipe: The purpose of the square steel pipe with a thickness of 5mm is to ensure the rigidity of the supporting tool of the hanging form. If the bathroom area is large, the thickness of the square pipe can be appropriately increased or the number of reinforced internal supports can be increased to ensure that the supporting tool of the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com