Dust-filtering-type wood processing equipment

A technology for dust filtering and processing equipment, applied in wood processing appliances, manufacturing tools, bark area/debris/dust/waste removal, etc., can solve problems affecting workers' health, waste of resources, flying debris, etc. Easy to collect and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

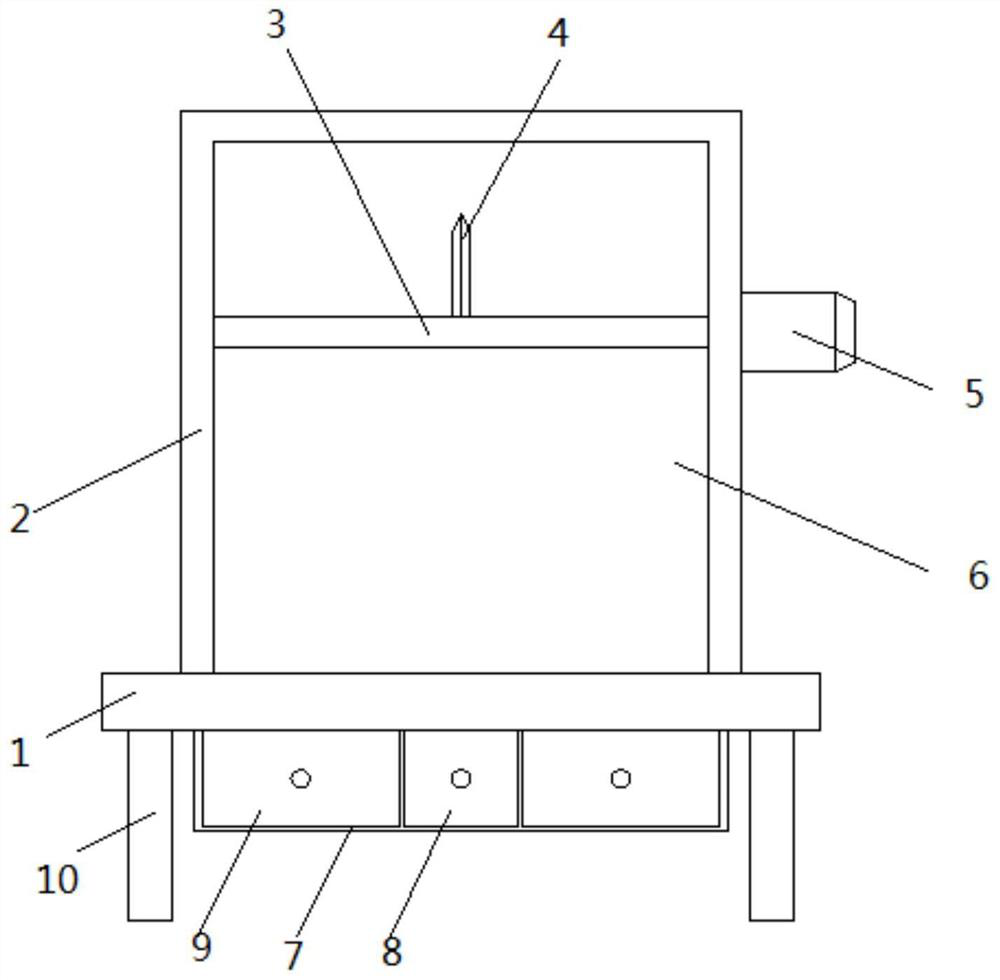

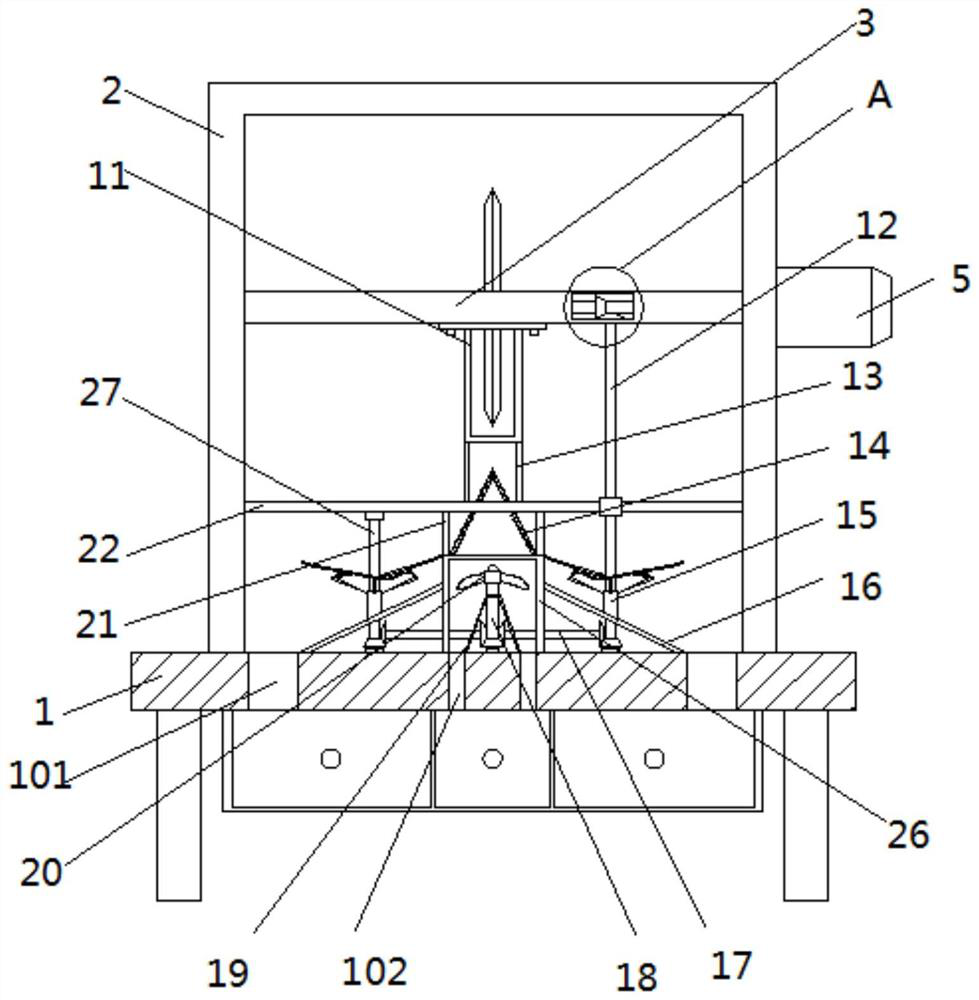

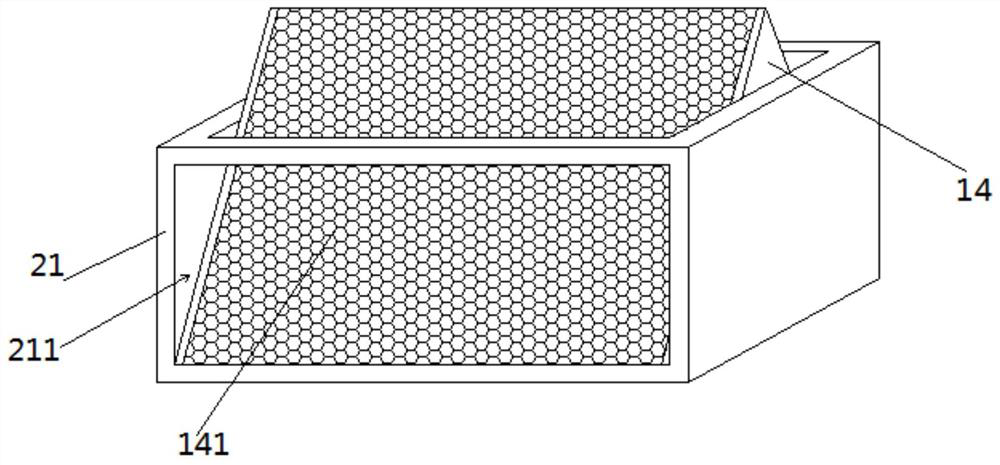

[0031] as attached figure 1 to attach Figure 9Shown: a dust filter type wood processing equipment, including base plate 1, molded plate 2, No.1 support plate 3, cutting wheel 4, servo motor 5, baffle plate 6, drawer bracket 7, No.1 drawer 8, No. Drawer 9, support foot 10, bottom plate 1 top center position is fixedly connected with 冂-shaped plate 2, is fixedly connected with a No. 1. The top is vertically fixedly connected with a baffle plate 6. The inside of the shaped plate 2 is located at the lower end of the No. 1 support plate 3 and is fixedly connected with the No. 2 support plate 22. The inner center of the No. 1 support plate 3 is horizontally connected with a drive shaft 23. The shaped plate 2 The upper end of the center position on the right side is fixedly connected with the servo motor 5, and the right side of the drive shaft 23 extends to the outside of the shape plate 2 and is fixedly connected with the output shaft of the servo motor 5, and the center position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com