A welding resistance equipment for axial flow fan casing processing

A technology for axial flow fans and casings, applied in resistance welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of large size, inconvenient operation, and lack, etc., and achieve high welding quality, reliable positioning, and fast assembly speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

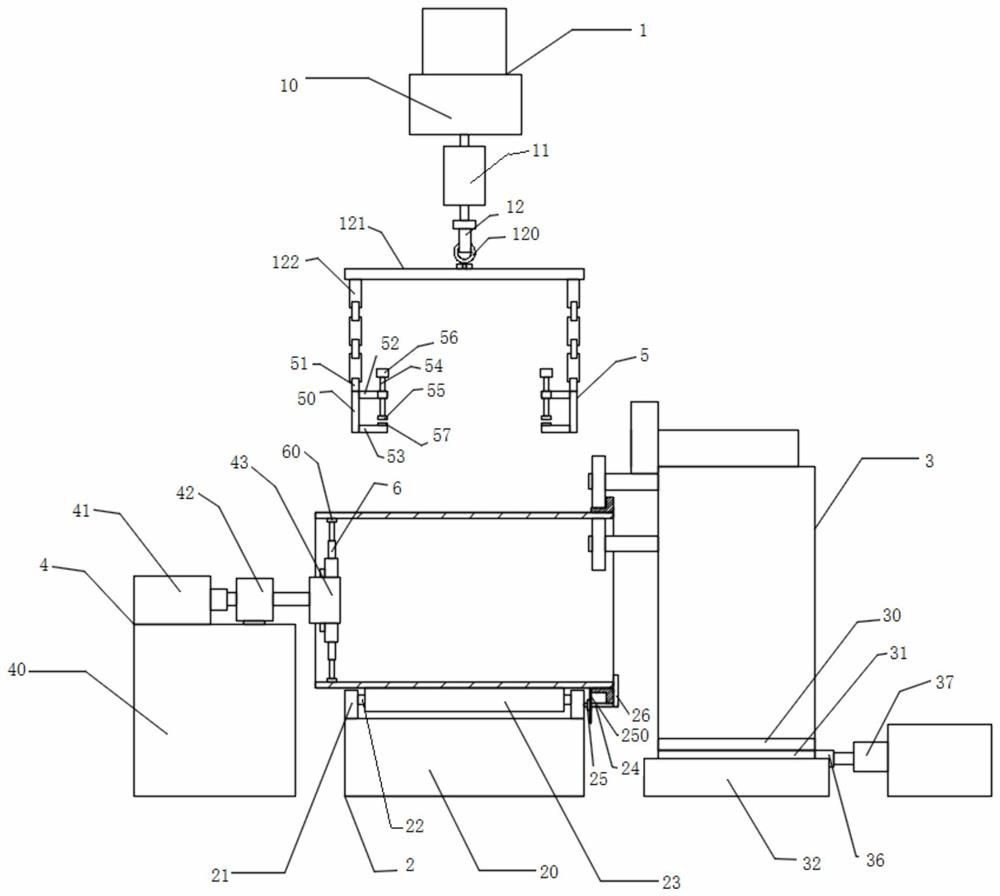

[0026] like figure 1 and figure 2 As shown, a welding resistance equipment for axial flow fan casing processing includes a mobile gantry crane 1, a stable rotating sliding seat 2 is provided under the mobile gantry crane 1, and a roller pressure welding is provided on one side of the stable rotating sliding seat 2 A resistance welder 3, the other side of the stable rotating sliding seat 2 is provided with a fixed rotator 4;

[0027] Described mobile gantry crane 1 comprises support 10, and the hook portion 120 of rotating hook 12 is hung on the suspension hook of the hoisting mechanism 11 of the electric hoist on the crossbeam of described support 10, and the bottom of described rotating hook 12 is provided with crossbeam 121, and described The bottom of both ends of the beam 121 is provided with connecting chains 122, and the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com