A multi-point synchronous dispensing machine and dispensing method

A technology of synchronous pointing and dispensing, which is applied in the field of dispensing machines, can solve problems such as complex design of shifting instructions, product bonding problems, and sequential solidification, etc., to achieve the effects of ensuring accuracy and fixing, stable work, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

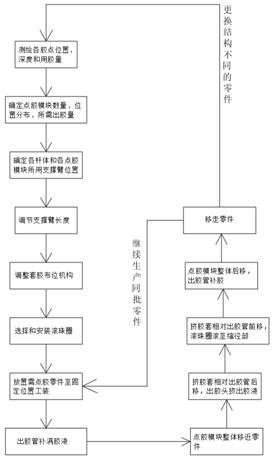

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0045] see Figures 1 to 6 , a multi-point synchronous dispensing machine, comprising:

[0046] see Figures 2 to 4 , a plurality of dispensing modules that perform the dispensing function, and the rear ends of the dispensing modules are connected to a rubber hose 18;

[0047] The module distribution mechanism fixes the position of the dispensing module; the module distribution mechanism includes a first frame body 31 and a plurality of polygonal rods 32 parallel to each other, and the rods 32 are distributed in the first frame body 31 and are connected to the first frame body 31. The frame body 31 can be locked and slidably fitted. The two ends of the rod body 32 are provided with sliders 321 respectively; 321 is screwed into and pressed against the first frame body 31 to realize the locking of the position of the slider 321. When the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com