Automatic loading device applicable to bagged materials and application method of automatic loading device

A material and packaging technology, which is applied in the field of automatic loading devices, can solve the problems of large labor force, inability to adapt to various types of transport vehicles, and low loading efficiency, and achieve the goals of reducing labor force, good economic and social benefits, and fast transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

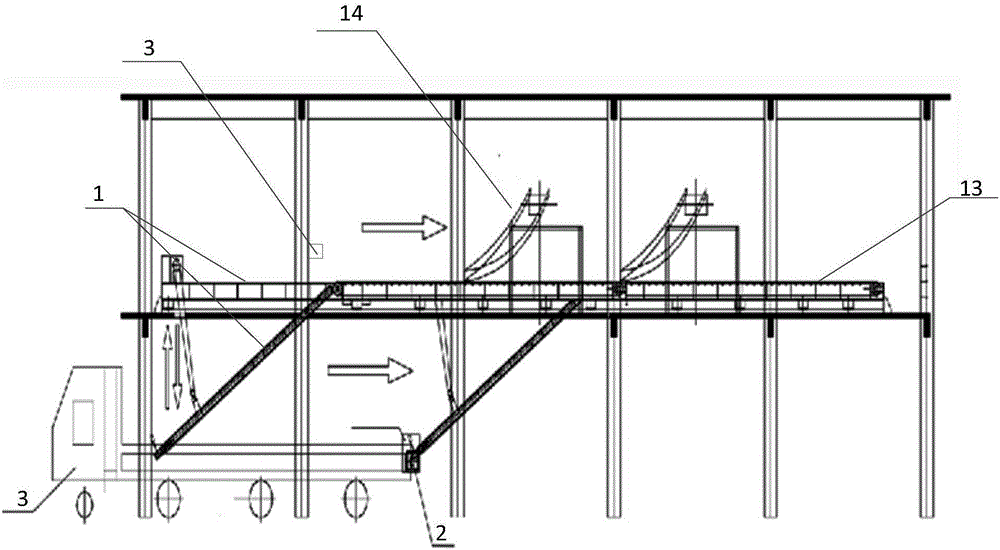

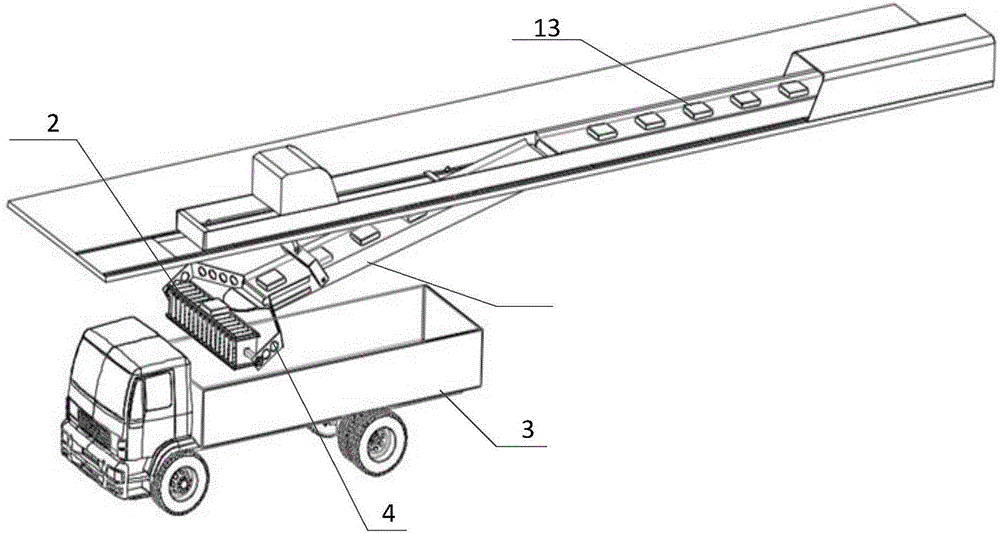

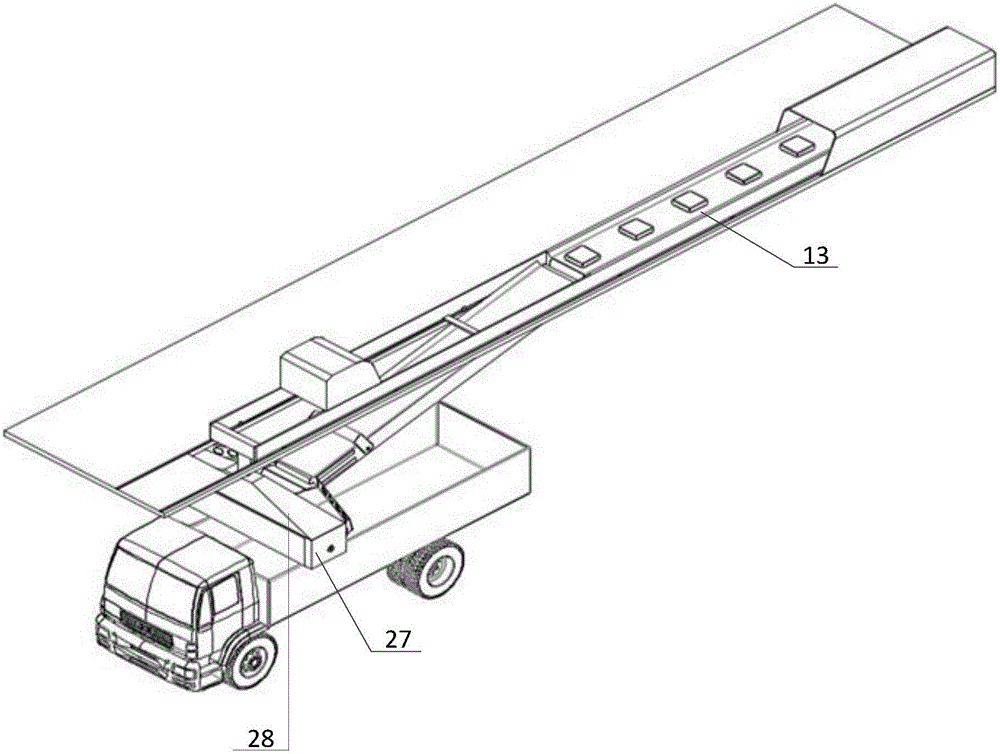

[0098] Automatic loading mechanism: turning mechanism + dust cover + electrical control system

[0099] First, the transformation of the original equipment, such as the inspection of the integrity of the cement bag, through the installation of a self-test box induction device on the material delivery unit, the self-detection of the unqualified cement bag material (damage of the cement bag, lax packaging) etc.), and then the unqualified products are removed from the main conveyor belt to the sub-conveyor belt through the sorting actuator, so that the cement bag on the discharge side of the final conveyor belt is intact, and the control device on the material delivery unit Install a control system to control the height and position of the material conveying unit so that it can meet the operation requirements of the next step.

[0100] Second, the material turning unit is mainly connected with the original material conveying unit. First, the electrical control system sets up an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com