Duplex clutches and clutch devices

A clutch and duplex technology, applied in clutches, friction clutches, mechanical drive clutches, etc., can solve the problems of huge, unreliable measurement data, complex structure of duplex clutches, etc., and achieve the effect of compact encoder part and reduced installation space requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

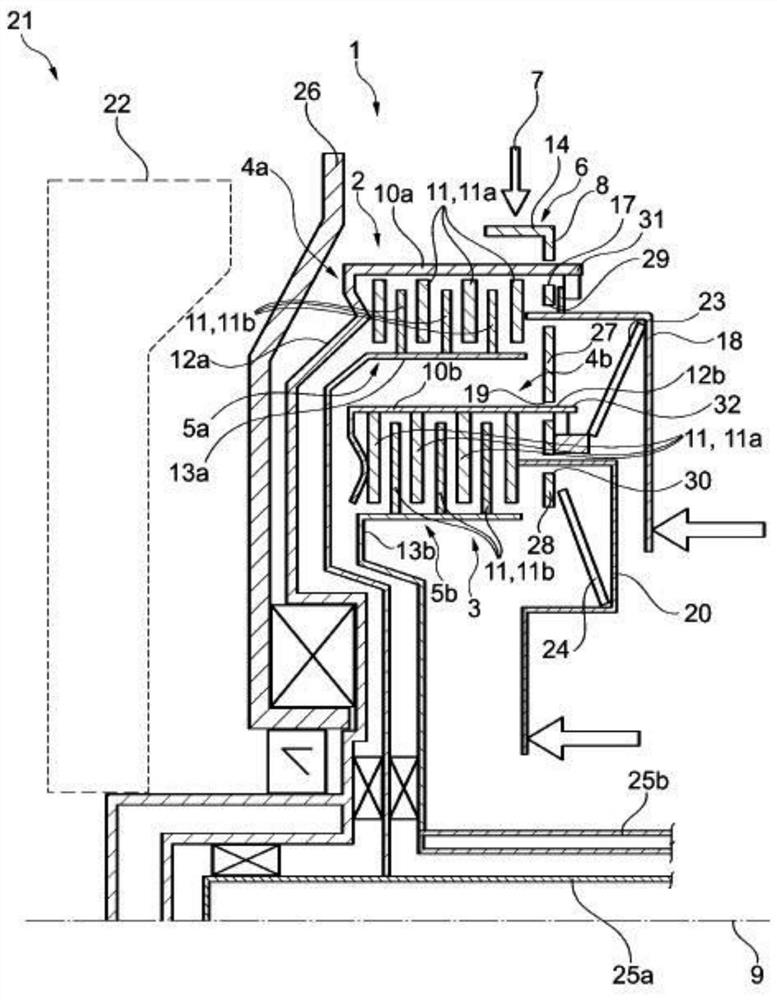

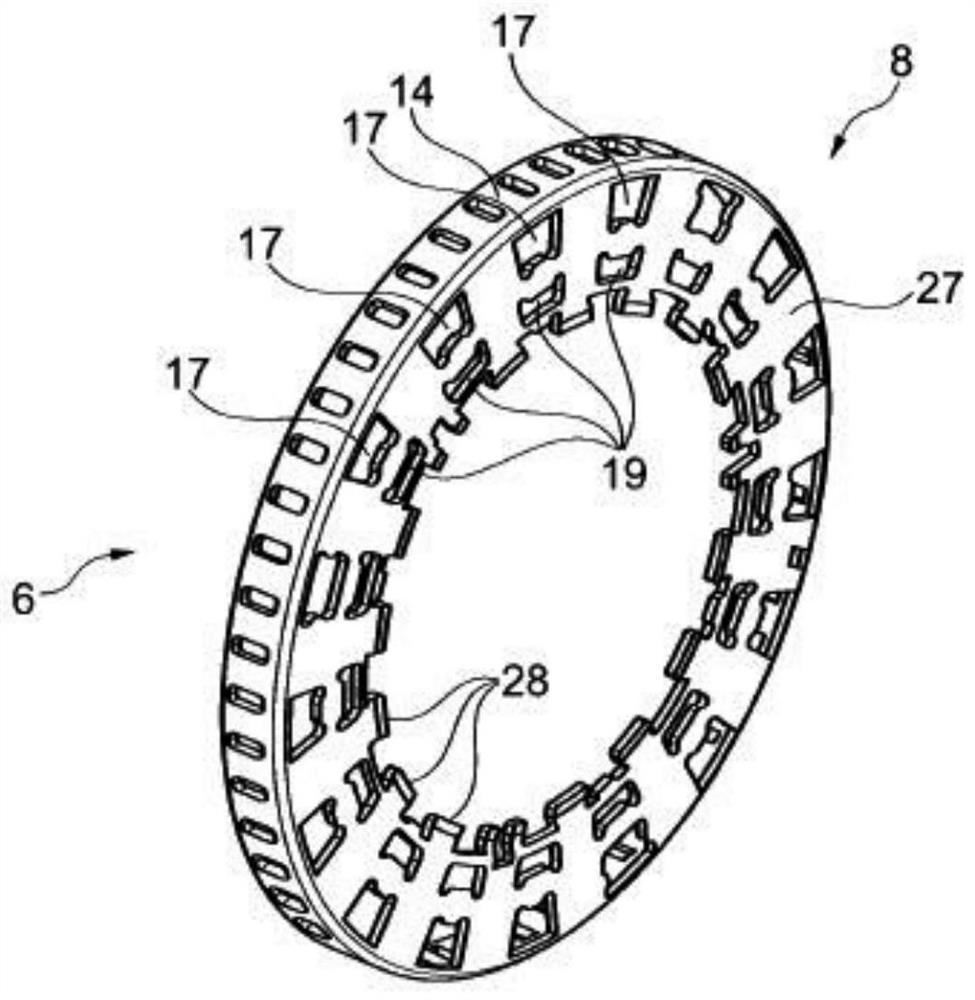

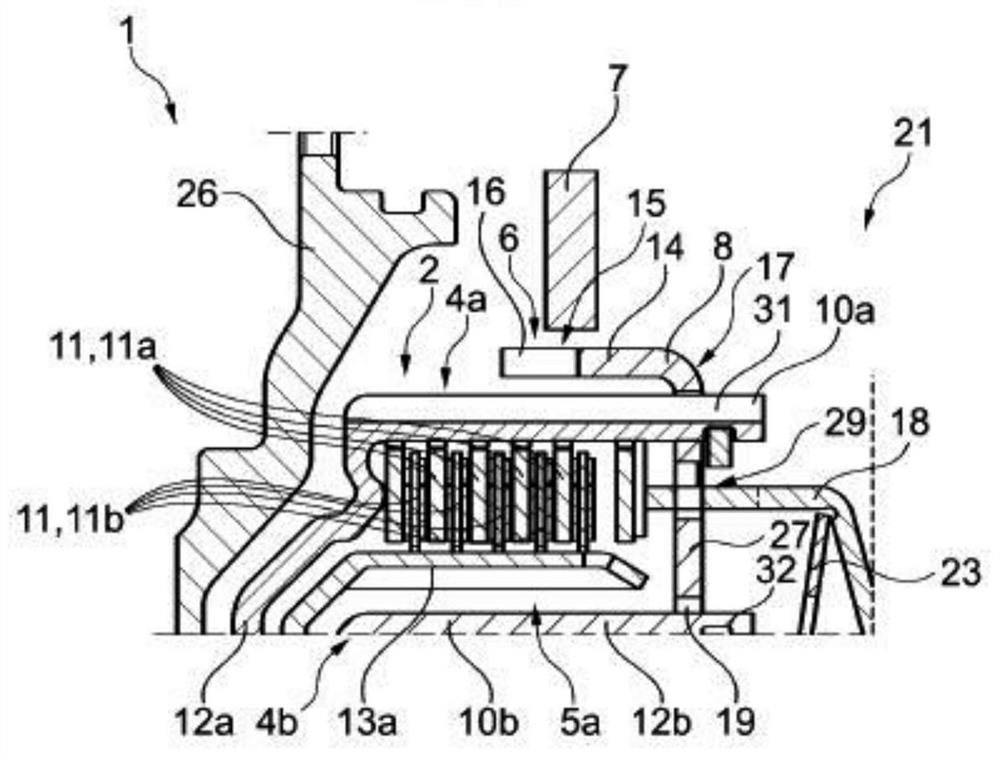

[0031] exist figure 1 In the diagram, the basic structure of the multiple clutch 1 according to the invention can be seen particularly clearly initially. In the exemplary embodiment, the multiple clutch 1 is realized as a double clutch; according to other embodiments, it is also designed as a triple clutch. The multiple clutch 1 has a first clutch 2 and a second clutch 3 . Viewed along the torque transfer path achieved during operation, the two clutches 2 and 3 are inserted between the output shaft of the internal combustion engine (not shown here for clarity) and the transmission input shaft 25a, 25b of the transmission (for clarity not shown in more detail). Thus, the multiple clutch 1 is part of the drivetrain of the motor vehicle during operation. In a preferred embodiment, as figure 1 As shown by the dashed line in , the multiple clutch 1 is operatively connected to the dual mass flywheel 22 . Then, during operation, between the output shaft of the internal combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com