Connecting wire and medical assembly

A technology of connecting wires and components, which is applied in the direction of connection, electrical components, devices with bendable leads, etc., and can solve the problems that the connecting wires do not have the function of anti-rotation and winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

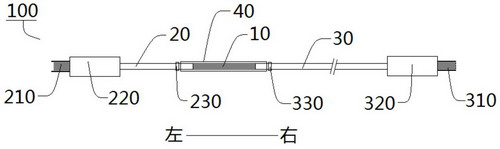

[0067] Such as figure 1 and figure 2 As shown, the connection wire 100 includes: a wire 10 , a first cable segment 20 , a second cable segment 30 and an insulating sleeve 40 .

[0068] Specifically, as figure 1 As shown, according to equipment design requirements, the connection line 100 has a plurality of parallel distributed wires 10, and each wire 10 has an insulating shielding sleeve. The conductor 10 is connected between the first cable segment 20 and the second cable segment 30, and the first cable segment 20 and the second cable segment 30 each have a plurality of inner cores having the same number as the conductors 10 and correspondingly connected to a plurality of conductors 10 .

[0069] It should be noted that all distributed wires 10 are complete continuations of the inner core wires 10 of the cable parts at both ends, that is, the part where the inner core of the first cable segment 20 extends into the insulating sheath 40 is the corresponding wire 10 . The l...

Embodiment 2

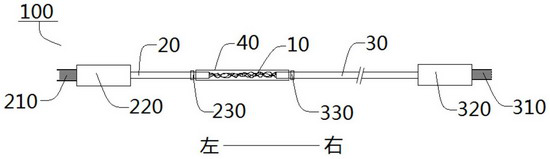

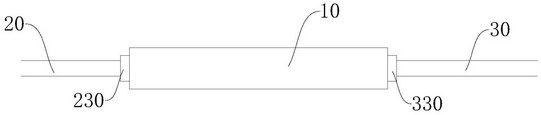

[0085] Such as Figure 3-Figure 10 As shown, the difference from Embodiment 1 is that in this embodiment, the first stopper 230 and the second stopper 330 are both ring-shaped, and the first stopper 230 is sheathed on the first cable segment 20 At the right end, the second stop portion 330 is sleeved on the left end of the second cable segment 30 .

[0086] Such as Figure 5 , Figure 7 and Figure 8 As shown, the outer peripheral walls of the first stop portion 230 and the second stop portion 330 are both provided with limiting ring grooves 231 extending in the circumferential direction. Correspondingly, as Figure 5 , Figure 9 and Figure 10 As shown, the two ends of the insulating sleeve 40 are respectively provided with a limit card edge 410 matching with the limit ring groove 231 . which, combined with Figure 5 , Figure 7-Figure 10 As shown, the limit card edge 410 at the left end of the insulating sleeve 40 can be fitted in the limit ring groove 231 of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com