Steel rail overhaul decision support method based on artificial intelligence

A decision support and artificial intelligence technology, applied in data analysis, railway rail maintenance and repair, can solve problems such as line fatigue damage, waste of resources, and inability to achieve precise rail replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

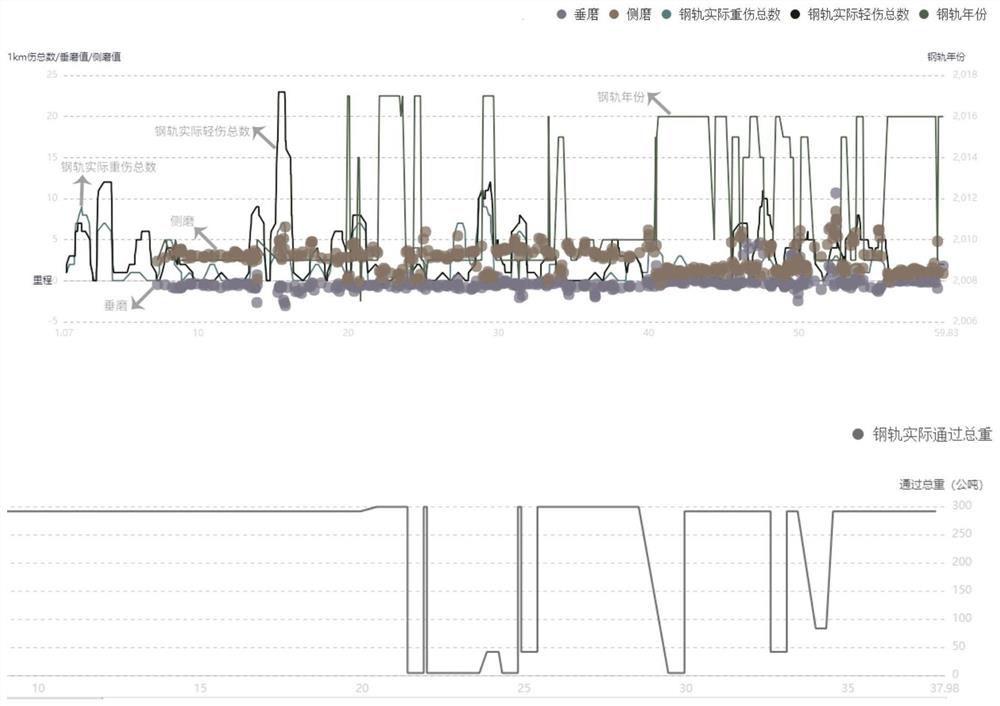

[0037] This example takes a 6-kilometer-long steel rail as an example for data collection and calculation.

[0038] S1, collecting characteristic data related to rail overhaul, and preprocessing the collected characteristic data, the processing steps are as follows:

[0039] S11, collecting the following characteristic data related to the rail overhaul: the vertical grinding of the rail, the side grinding of the rail, the total weight passed, the historical rail change interval, the number of serious injuries in 1km, the number of minor injuries in 1km, the year of the rail;

[0040] S12, preprocessing the collected characteristic data, and processing missing values and abnormal values in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com