Automatic weighing system and sampling method thereof

An automatic weighing and sampling rod technology, applied in weighing, sampling, cleaning methods using gas flow, etc., can solve the problems of poor control accuracy, low sampling accuracy, complicated operation, etc., to ensure sampling accuracy, facilitate automation, The effect of convenient cleaning operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

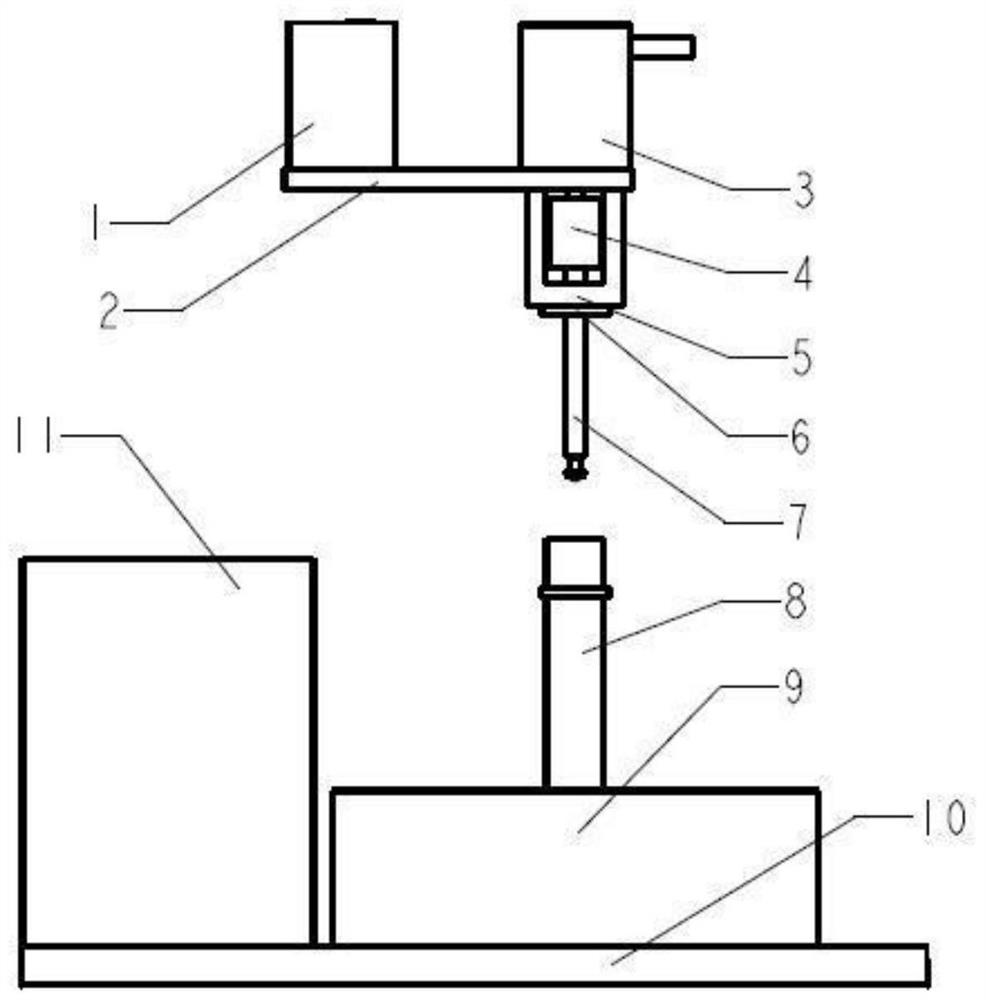

[0036]An automatic weighing system includes a sampling module, a weighing module and a cleaning module, and the sampling module includes a sampling rod 7 and a driving device. The driving device includes a manipulator 1, a connecting plate 2 and a motor 3, the manipulator is used to control the up, down, left, and right movement of the connecting plate, the connecting plate is fixed with a motor, and the motor is fixed with a bearing holder 5 through a shaft coupling 4, Bearings are arranged on the bearing fixing seat for connecting the sampling rod, and the driving device controls the rotation and movement of the sampling rod through a program.

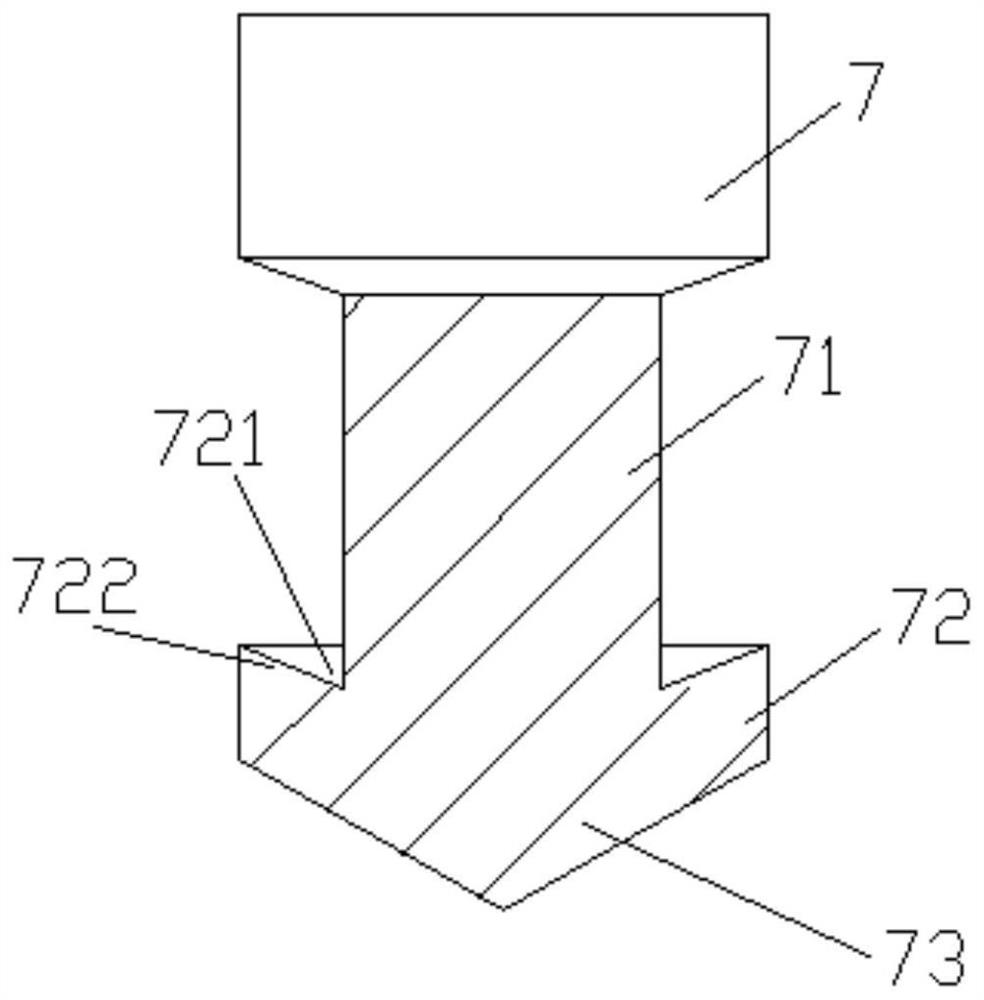

[0037] The bottom of the sampling rod is provided with a detachable sampling head. The sampling head includes a connecting portion 71, a sampling portion 72 and a guide portion 73. One end of the connecting portion is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com