Small large-resistance buffer

A buffer and resistance technology, applied in the field of small and large resistance buffers, can solve the problems of high resistance value products, increase the reverse rebound resistance of the piston rod, and high requirements for small hole processing, and solve the problem of large resistance value products. , easy to control and guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

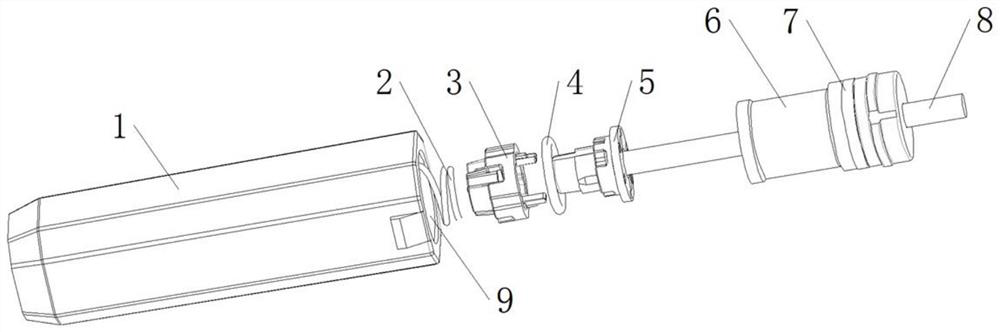

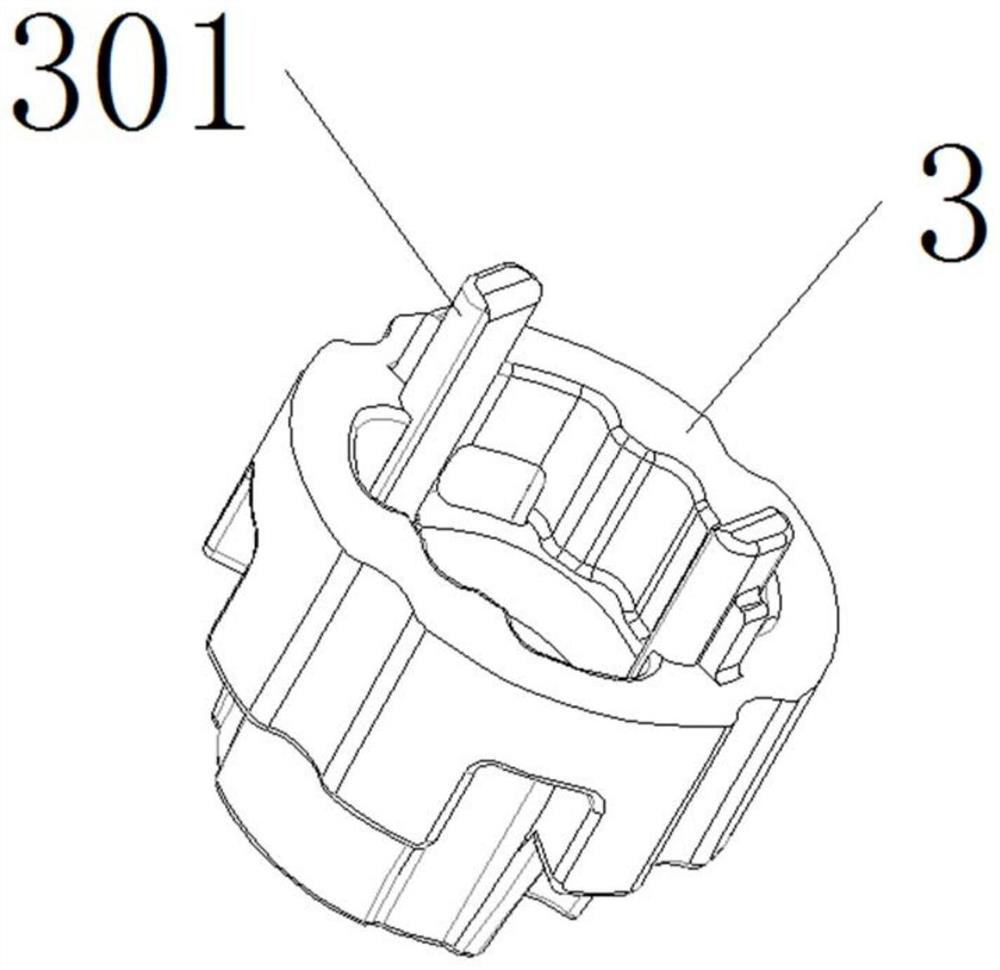

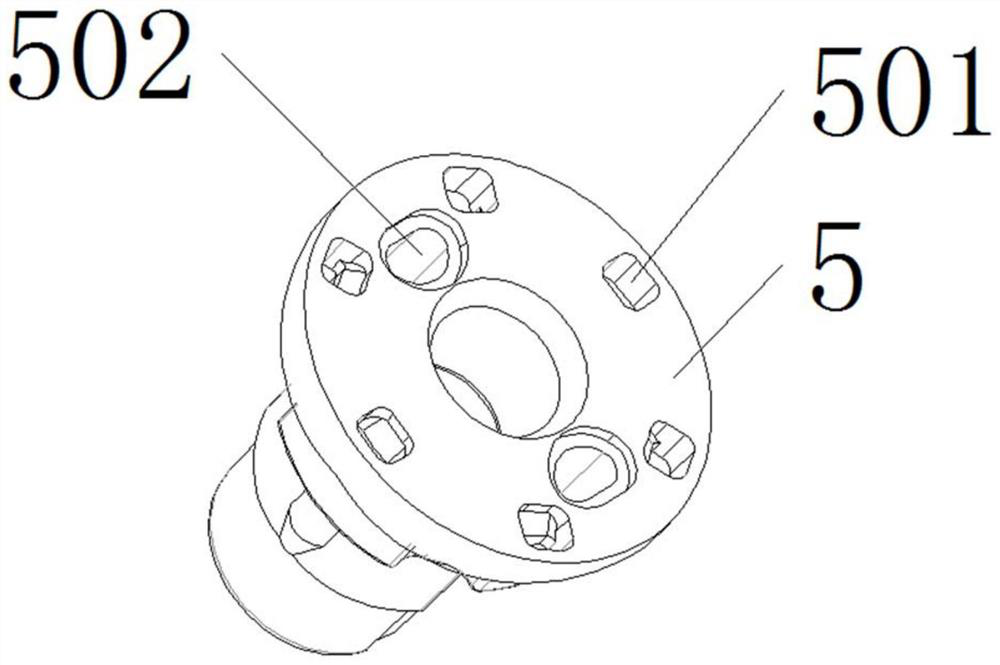

[0033] When the piston 5 is pressed down by an external force, the O-ring 4 is stuck to the inner wall of the housing 1 and remains still, and at the same time, the damping oil layer 9 in the B chamber pushes the O-ring 4 to align with the lower plane of the piston 5 through the groove of the seat cover 3, Close the convective through hole 501 on the piston 5, so that the damping oil layer 9 in the B chamber completely passes through the small oil hole formed by the protruding shaft 301 and the through hole 501. The small cross-sectional area of the oil hole makes the damping oil layer between the A and B chambers 9 The hydraulic pressure difference is large, and the stroke has a large reverse resistance effect.

Embodiment 2

[0035] When the piston 5 is under the action of the elastic force of the spring 2, it produces a rebound and reset action, and the damping oil layer 9 in the A chamber flows through the convection hole 502 on the piston 5, and the O-ring 4 is squeezed to move down, completely opening the damping of the A chamber and the B chamber. The convection channel composed of the protruding shaft 301 and the through hole 501 in the oil layer 9 has a large cross-sectional area, so that the hydraulic pressure difference of the damping oil layer 9 between the A and B rooms is small, and the reverse resistance value is small. Under the action of elastic force, the piston 5 can be reset to the original position at the top.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com