Three-phase FeC reaction device for treating high-concentration coking wastewater

A coking wastewater and reaction device technology, applied in the direction of oxidized water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve problems such as easy precipitation, limited reaction speed, and viscous reaction products, and achieve Good treatment effect, small footprint and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

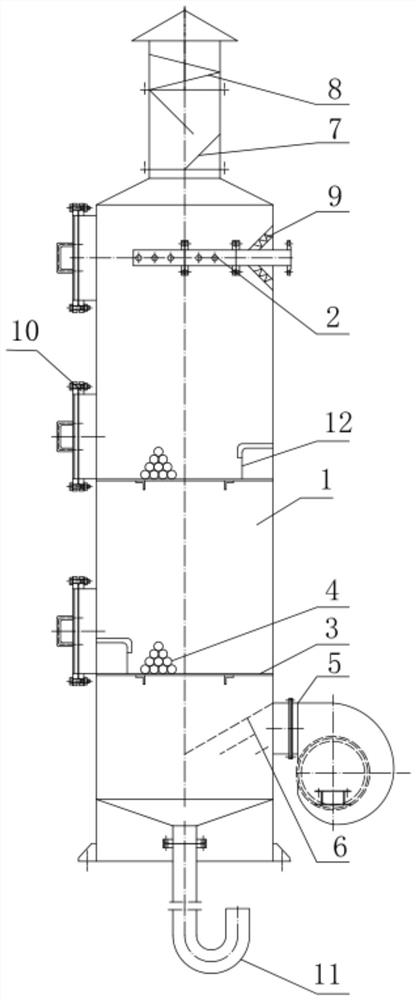

[0027] The three-phase FeC reaction device for high-concentration coking wastewater treatment of the present invention consists of a tower body 1, a spray water distributor 2, a float valve tray 3, an FeC filler 4, an aeration fan 5, an air flow redistributor 6, a folding It is composed of flow dehydrator 7, cyclone dehydrator 8, elastic damper 9, automatic discharge manhole 10, liquid discharge pipe 11 and liquid redistributor 12.

[0028] The tower body 1 is a vertical tower body, and the tower body 1 is lined with low calcium magnesium rubber to solve the corrosion problem. The top of the tower body 1 is provided with a spray water distributor 2, which is connected to the spray water inlet. Preferably: the spray water distributor 2 adopts a titanium alloy gull-wing wire-wound pipe water distributor (titanium alloy The cross section of the wire is gull wing shape). The spray water distributor 2 is installed in the tower 1 through an elastic damper 9.

[0029] At least one layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com