Industrial robot composite clamp

A technology of industrial robots and fixtures, applied in the direction of manufacturing tools, manipulators, etc., can solve the problems of damaged fixtures, occupying a lot of space, and workers being injured, and achieve the effect of reducing the overall space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

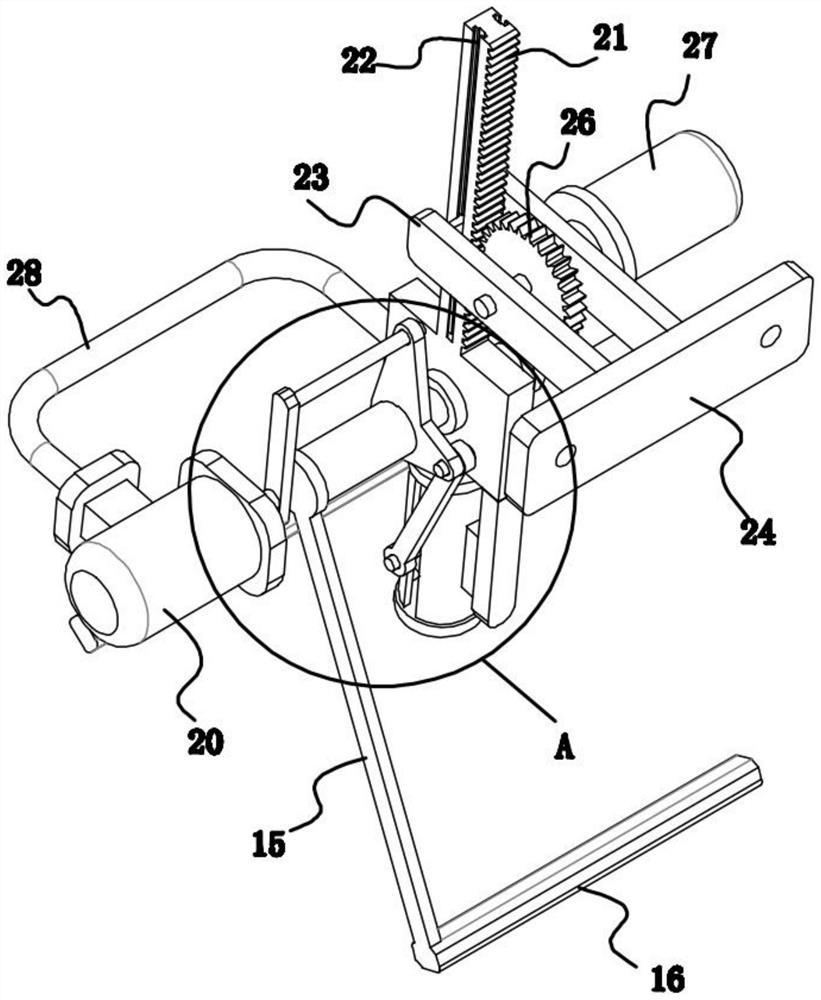

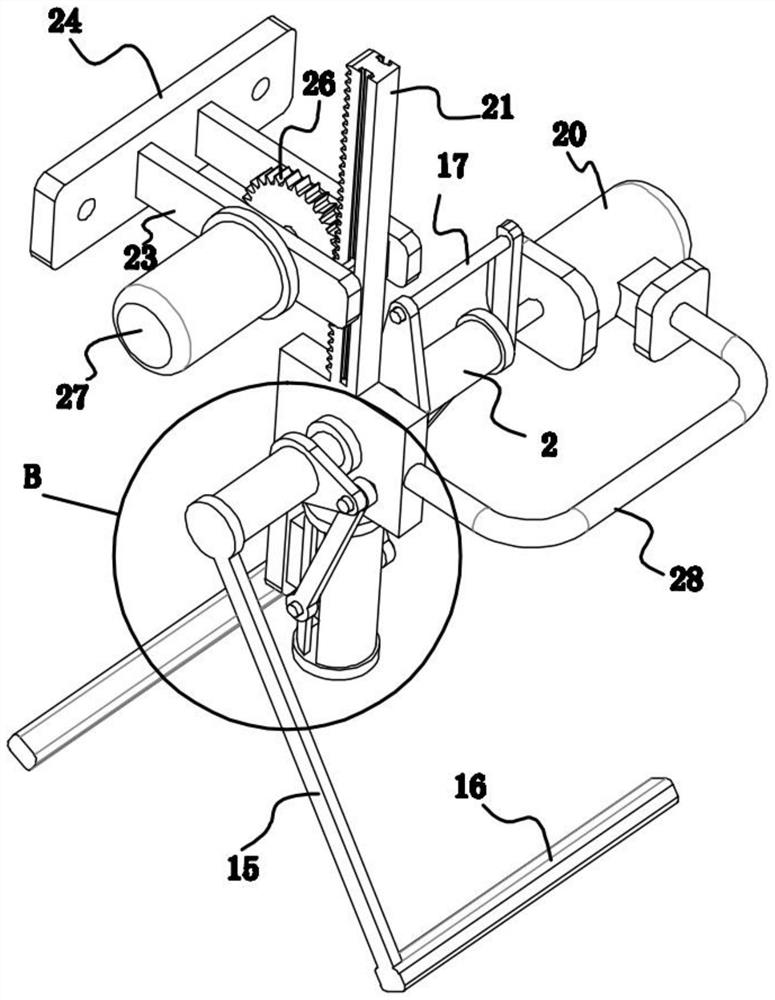

[0023] refer to Figure 1-7 , an industrial robot composite fixture, including a fixed plate 1, a vertically arranged central axis 19 is fixedly installed on the fixed plate 1, and both ends of the central axis 9 extend outward until they pass through the fixed plate 1, and the outer end of the central axis 9 The first sub-shaft 2 and the second sub-shaft 5 coaxially arranged therewith are respectively rotatably mounted on them, and a rod body 15 is fixedly installed on the outer ends of the first sub-shaft 2 and the second sub-shaft 5 , and the rod body 15 A splint 16 is fixedly installed on the inner surface of each, the first sub-shaft 2 and the second sub-shaft 5 are connected to the same driving module by transmission, and a lifting module is fixedly installed on the top of the fixed plate 1 .

[0024] The driving module includes a driving plate 3, a first connecting plate 4, a second connecting plate 6, a transmission mechanism, and a first driving mechanism. A connecti...

Embodiment 2

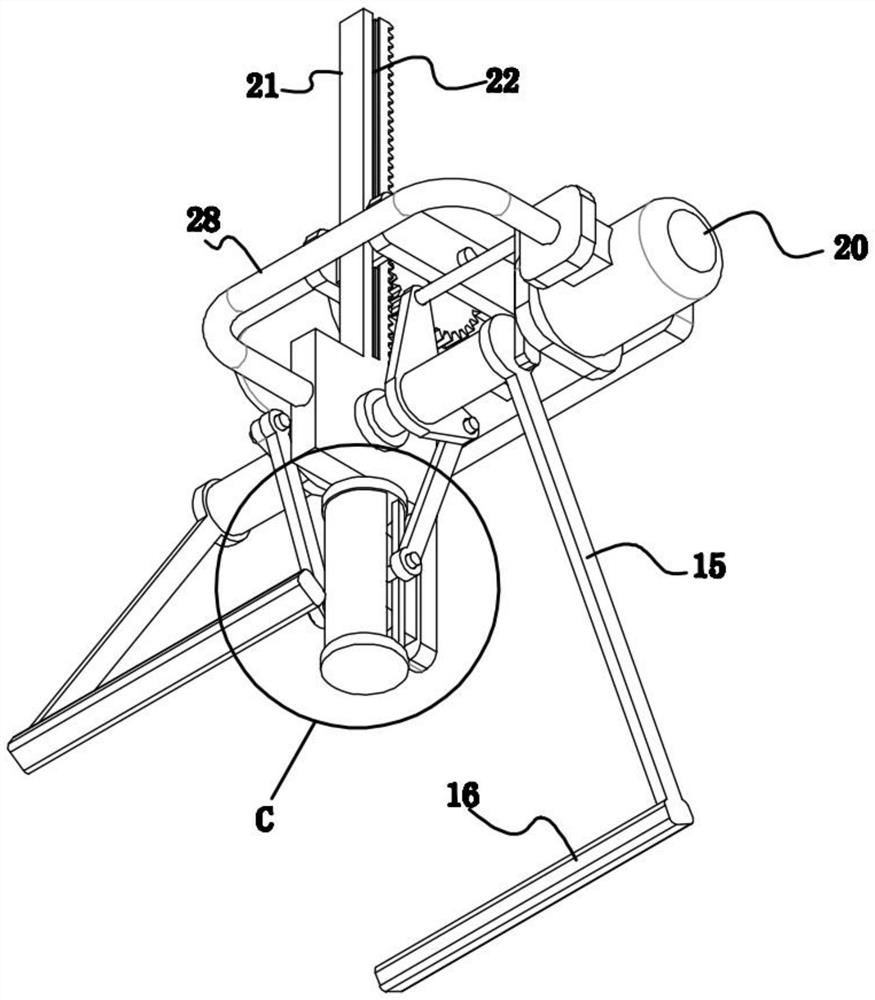

[0029] refer to Figure 1-7 As another preferred embodiment of the present invention, the difference from Embodiment 1 is that the lifting module includes a rack 21 and a second driving mechanism, the top of the fixed plate 1 is fixedly equipped with a rack 21, and the rack 21 is uploaded and connected to a second drive mechanism. Two driving mechanisms. The second drive mechanism comprises chute 22, side plate 23, mounting plate 24, drive shaft 25, gear 26, second motor 27, all has chute 22 along its length direction on two corresponding sides of rack 21, every A slide block can be slidably installed in each of the chute 22, and a side plate 23 is fixedly connected to each slide block, and the two side plates 23 are arranged parallel to each other, and the same-side end between the two side plates 23 A mounting plate 24 is fixedly installed, and a drive shaft 25 is installed rotatably between the two side plates 23. A gear 26 coaxially arranged with it is fixedly installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com