Automatic PCM heat radiating paste coating equipment

A heat dissipation paste and coating technology, which is applied in coatings, devices for coating liquid on the surface, etc., can solve problems such as increased labor costs, increased equipment investment, and inability to guarantee the quality of quality inspection, and achieves improved accuracy and efficiency. , work efficiency improvement, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

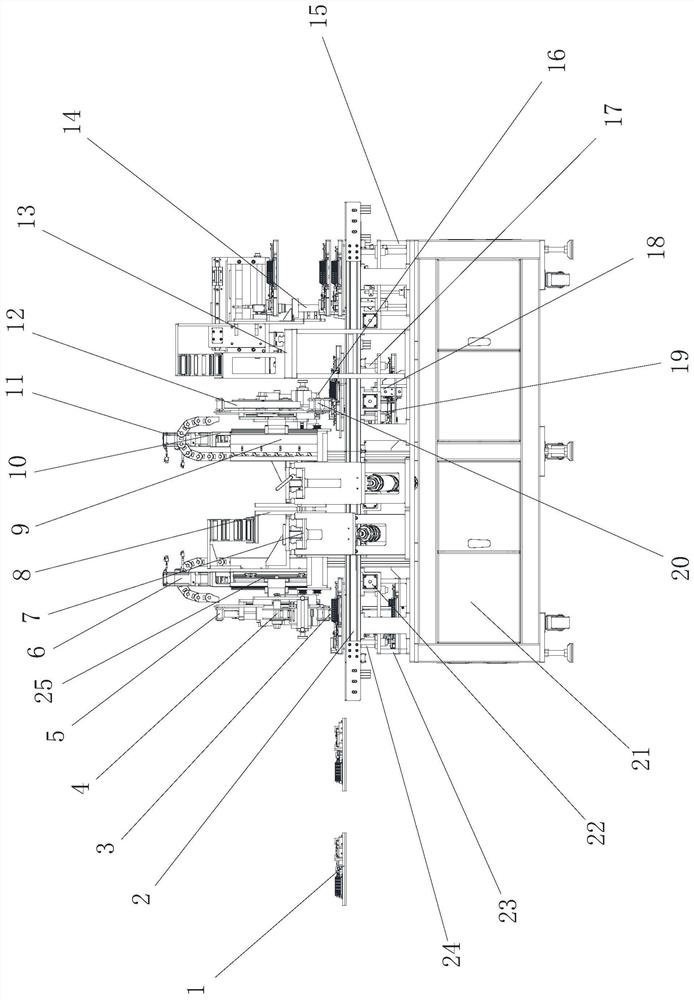

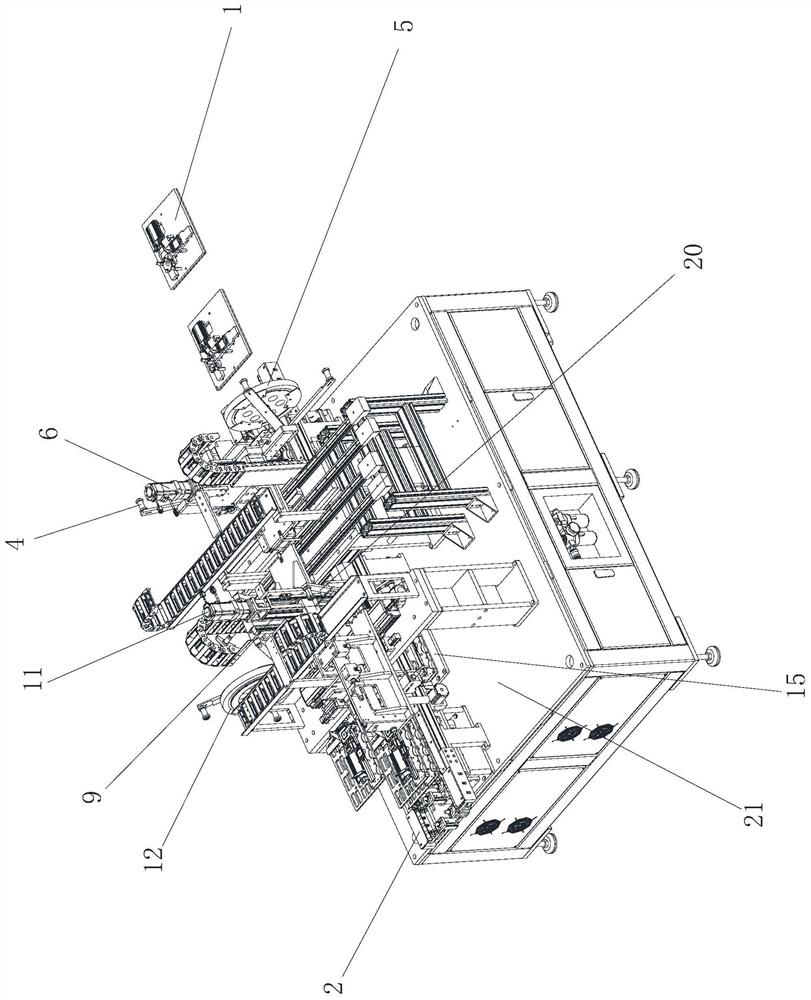

[0018] Such as Figure 1-2 As shown, an automatic PCM heat dissipation paste coating equipment includes a frame 21, a track 2 is arranged on the frame 21, a conveying device is arranged on the track 2, and three jacking devices are arranged on the frame. The conveying device includes a conveying motor 22 in the mounting frame, and two rows of rotating shafts are evenly arranged on the track, and all the rotating shafts are connected with two conveyor belts, and the conveying motor 22 is connected to one of the rotating shafts through a transmission belt. Workpieces such as PCM are placed on a fixed pallet, which is placed on two conveyor belts, and enters the frame along the moving direction of the conveyor belt, and the first transfer, the second transfer, and the second are sequentially realized at the three jacking devices. Secondary transfer and photo quality inspection.

[0019] The working area of the jacking device is between two conveyor belts and two rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com