Resist agent preparation process implementation system with high production efficiency

A technology of production efficiency and preparation process, applied in the field of anti-dye preparation preparation process implementation system, which can solve the problems of low degree of automation, poor anti-dyeing effect, shallow dyeing degree, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

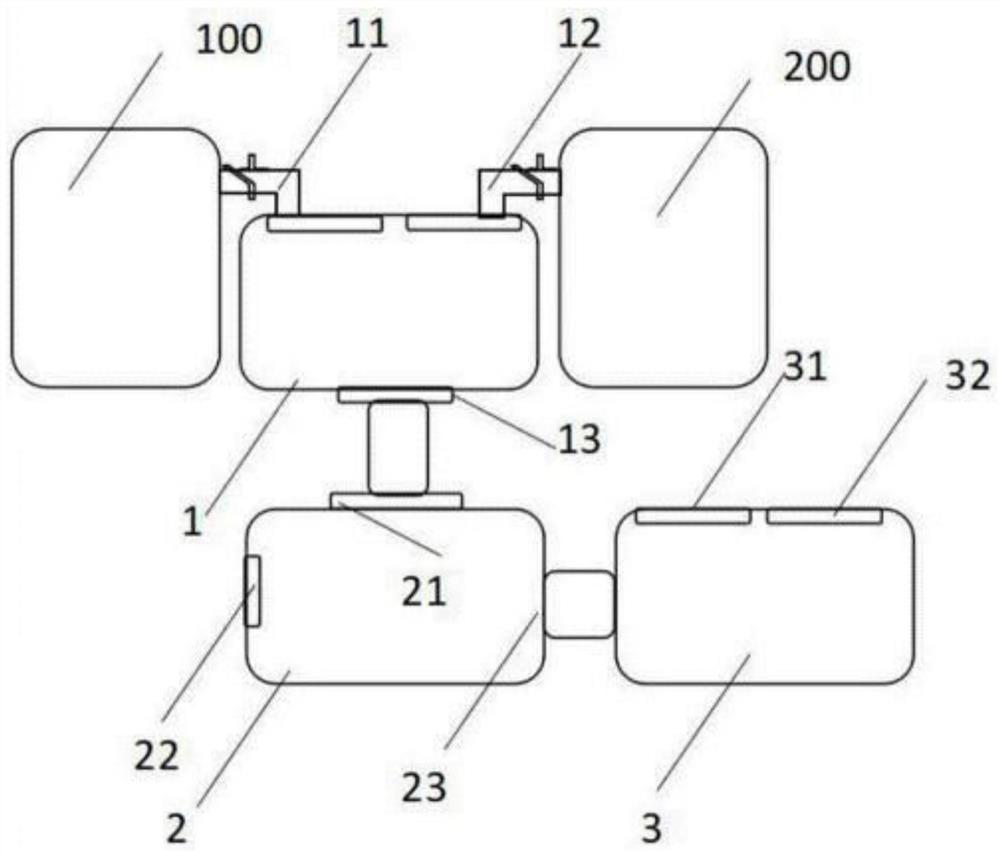

[0023] The embodiment of the present invention provides a kind of anti-dyeing agent preparation process implementation system with high production efficiency, such as figure 1 shown, including:

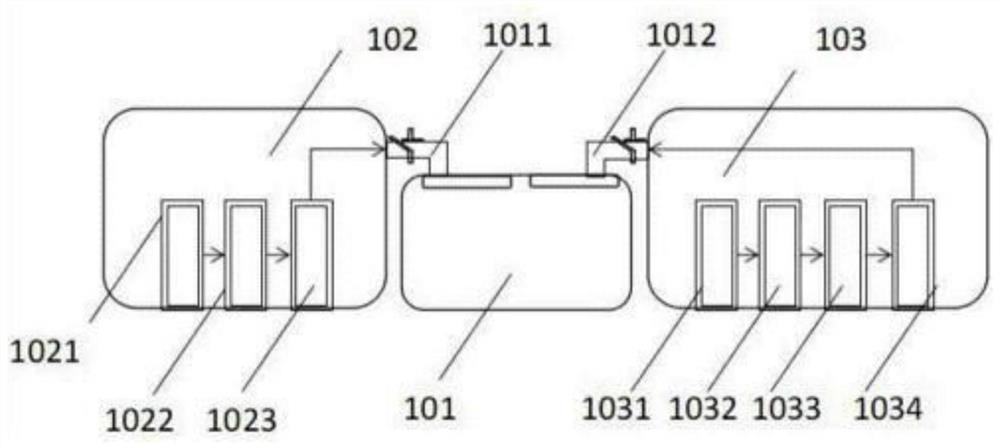

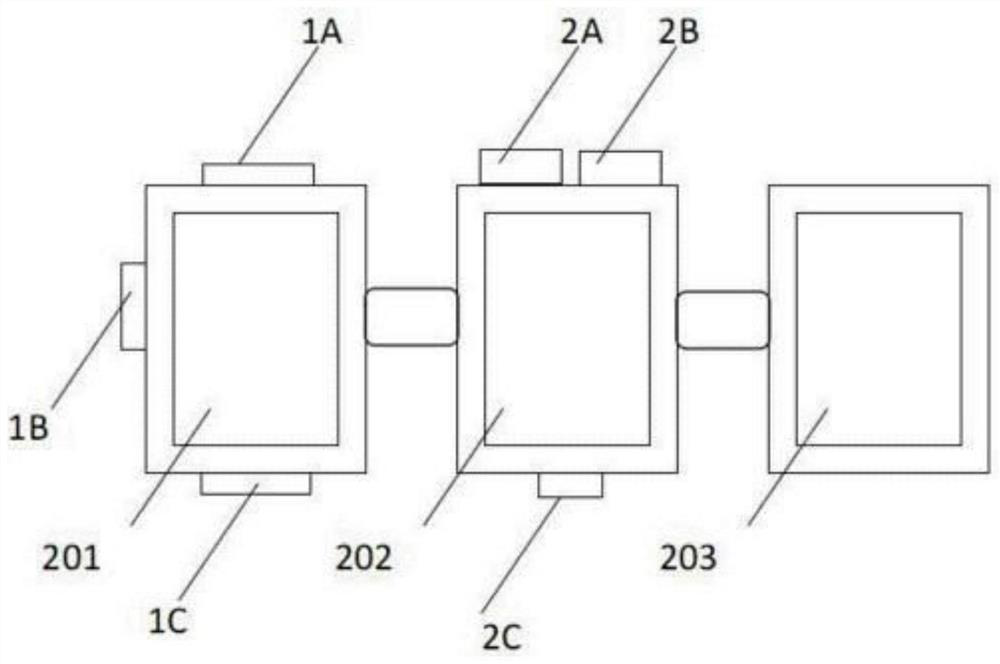

[0024] The first preparation pool 1, the second preparation pool 2 and the treatment pool 3 are connected in series in sequence, the first preparation pool 1 includes a first reagent injection port 11 for injecting an antifouling agent and a second reagent for injecting a penetrating agent The injection port 12, the first preparation pool 1 also includes a first discharge port 13, the first discharge port 13 communicates with the feed port 21 of the second preparation pool 2, and the second preparation pool 2 It also includes a third reagent injection port 22 , and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com