Slow-closing type outdoor alternating-current high-voltage isolating switch with built-in fracture

A high-voltage isolating switch, isolating switch technology, applied in the direction of electrical switches, air switch parts, electrical components, etc., can solve the problems of unstable closing, aging of main circuit contacts, incomplete closing, etc., to simplify production and assembly Simple process, simple structure and reliable interlocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

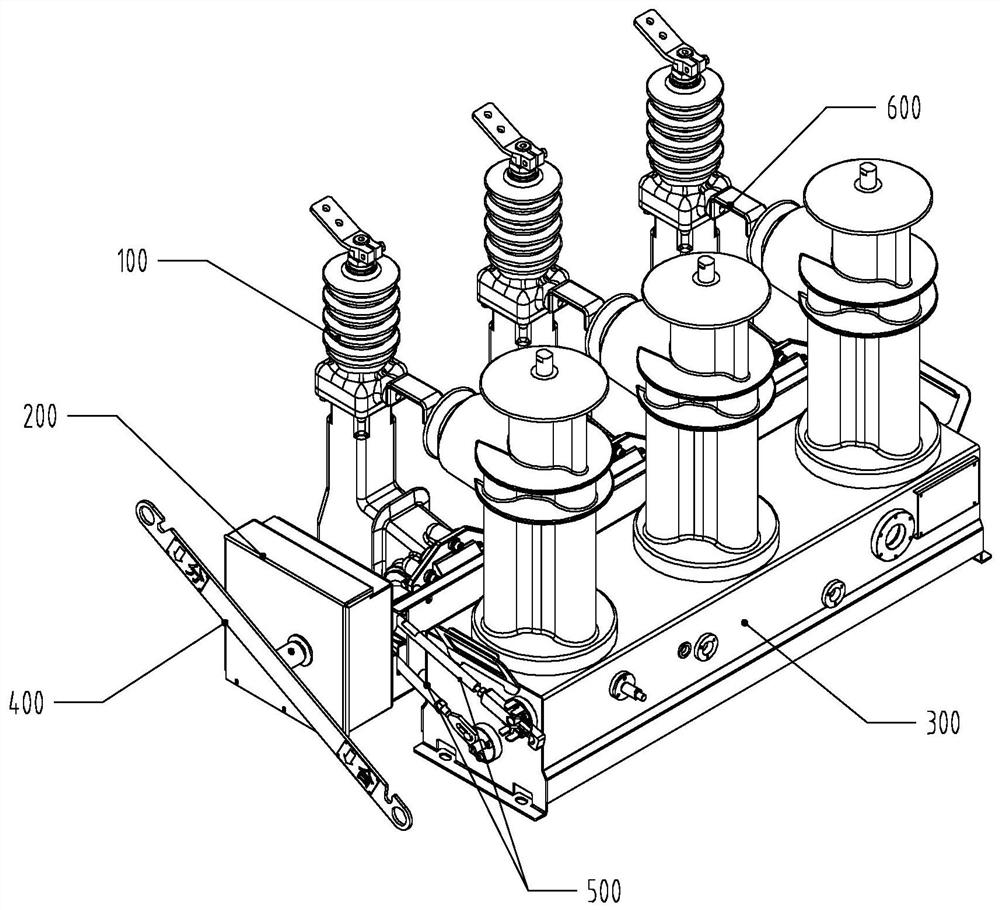

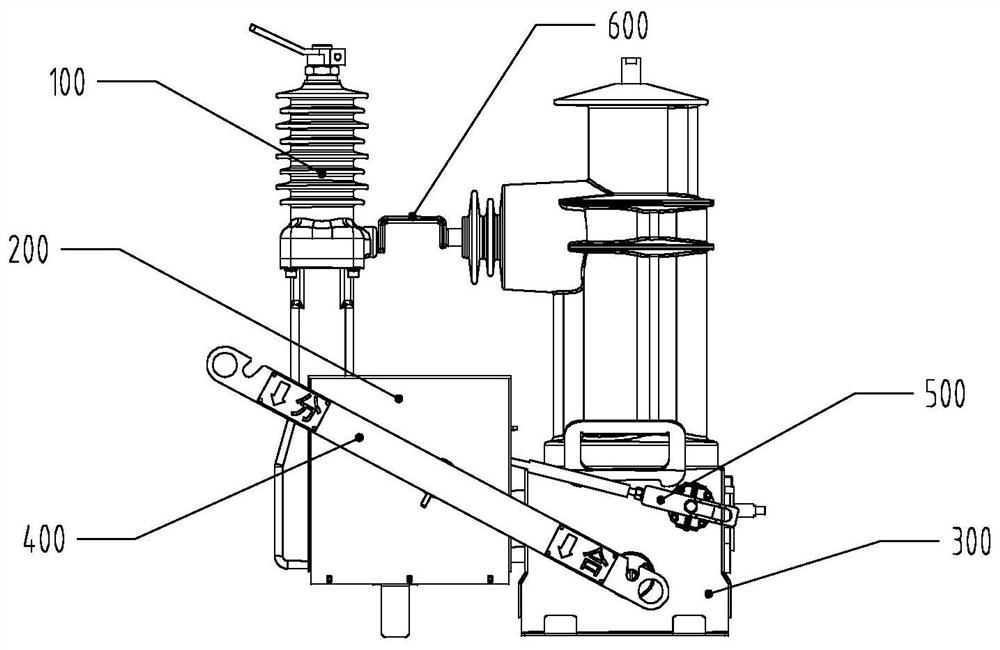

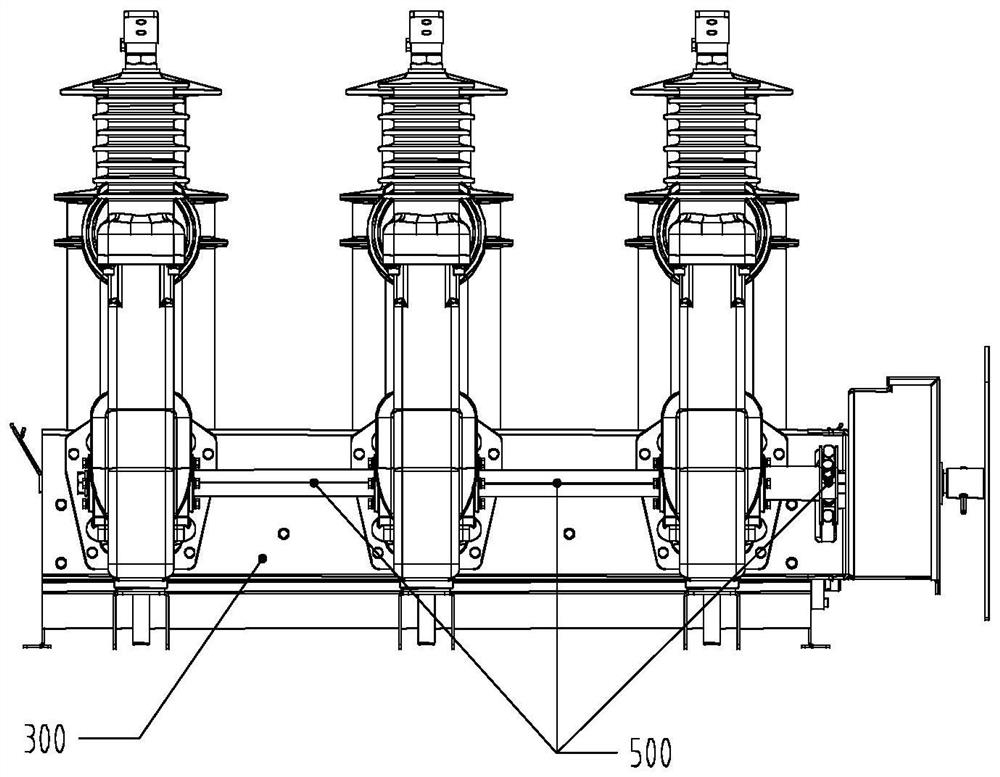

[0044] Such as figure 1 , figure 2 and image 3 As shown, the present invention has a slow closing type built-in fracture outdoor AC high-voltage isolating switch, including a main circuit unit 100, a main frame member 300, an operating unit 200, an operating handle 400, an interlocking transmission unit 500 and a connecting row 600, and the main frame member The main switch 700 is arranged above the 300, and the main circuit unit 100 is used to control the opening and closing of the isolating switch. The main circuit unit 100 is connected to the main switch 700 through the connecting row 600, and the main circuit unit 100 is connected to the main frame member 300 by bolts. The operating unit 200 is connected to the main circuit unit by driving the crank arm. The operating unit 200 is used to drive the main circuit unit to perform actions t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com