Method for calculating flexural rigidity of externally-wrapped corrugated side plate-concrete composite beam

A flexural rigidity, concrete technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as complex calculation formulas, achieve good application prospects, convenient and fast methods, and omit the effect of coefficient calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for calculating the flexural stiffness of an outsourcing corrugated side plate-concrete composite beam comprises the following steps:

[0037] 2. A method for calculating the flexural stiffness of an outsourcing corrugated side slab concrete composite beam, characterized in that it comprises the following steps:

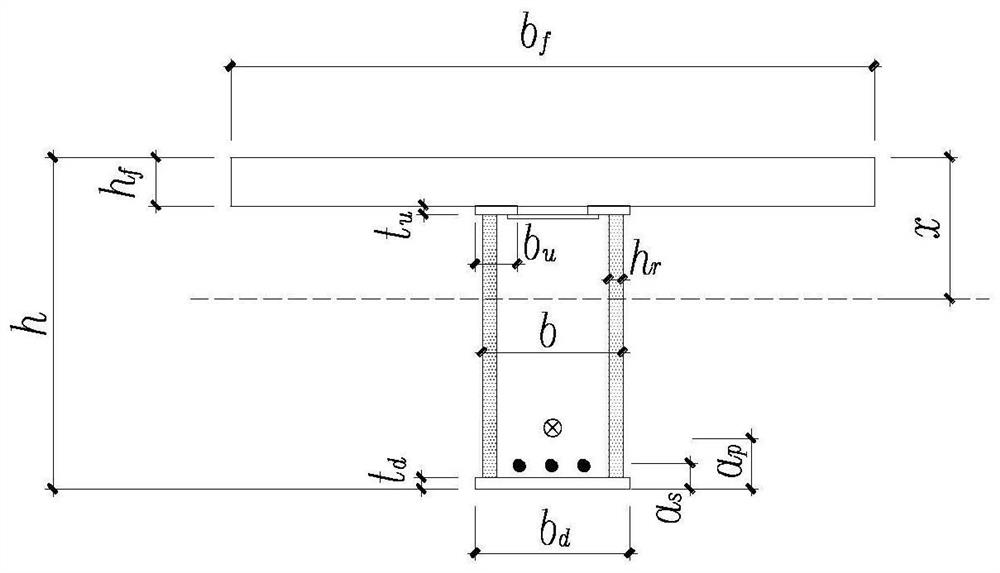

[0038] S1, obtain the thickness t of the steel roof of the corrugated side plate-concrete composite beam u and width t d ; Get the wave height h of the corrugated side plate r , Beam section height h and width b, get the width b of the floor slab of corrugated side slab-concrete composite beam f and height h f , to obtain the elastic modulus E of the concrete c and the elastic modulus E of the steel a ;

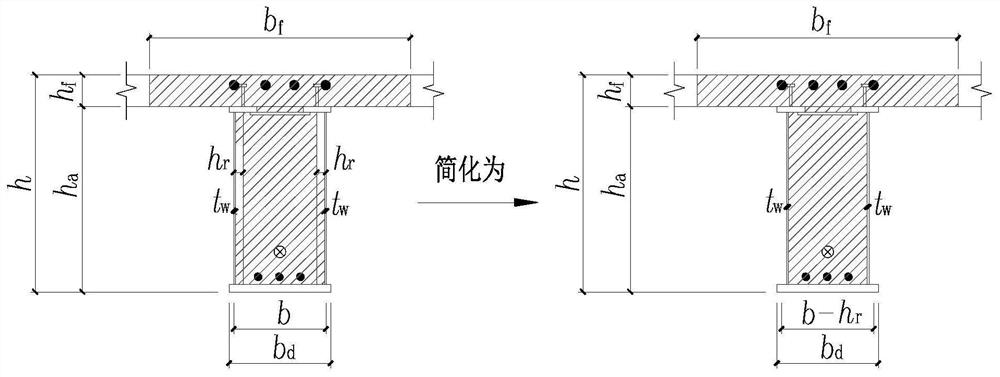

[0039] S2, calculate the average value of the width at the crest and the width at the trough of the corrugated steel plate, and use the average value as the effective section width of the concrete in the corrugated steel plate;

[0040] S3, ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com