High-pressure gas refractive index precision measurement method

A precision measurement and high-pressure gas technology, applied in the field of optics, can solve the problems of inability to measure the refractive index of high-pressure gas precisely, and achieve the effects of reducing accidental errors, precise measurement, and avoiding accidental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

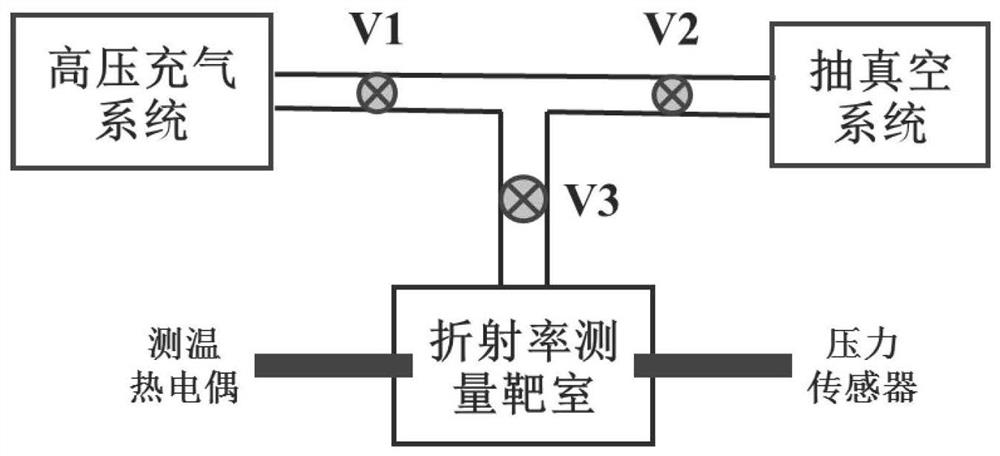

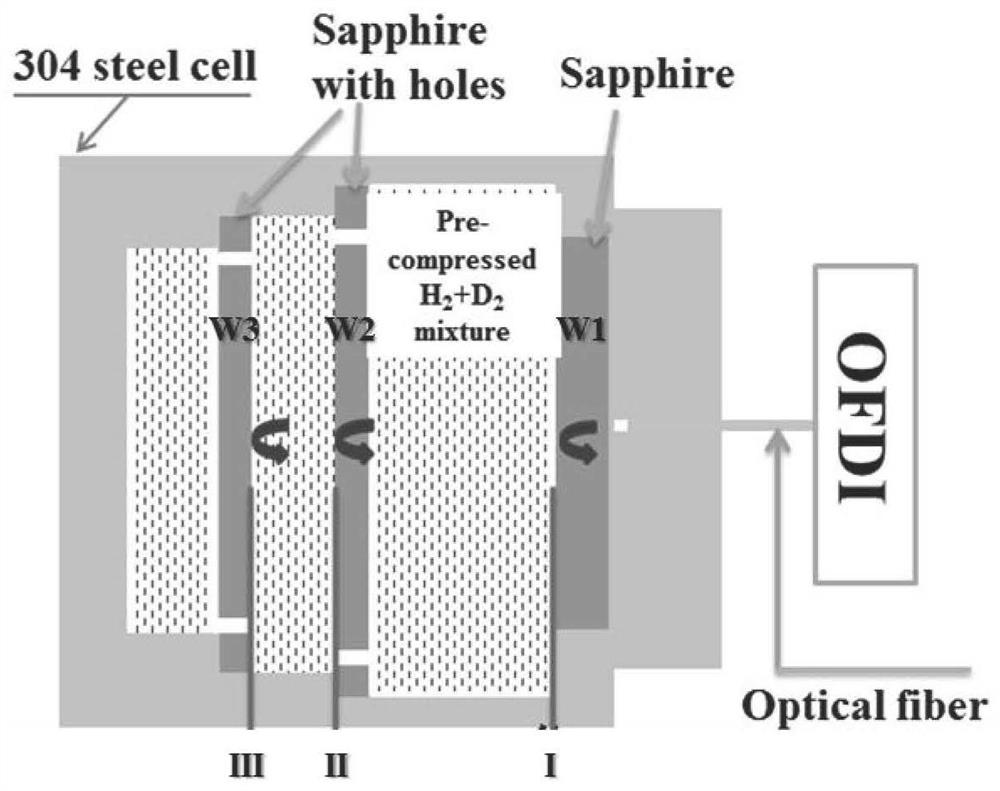

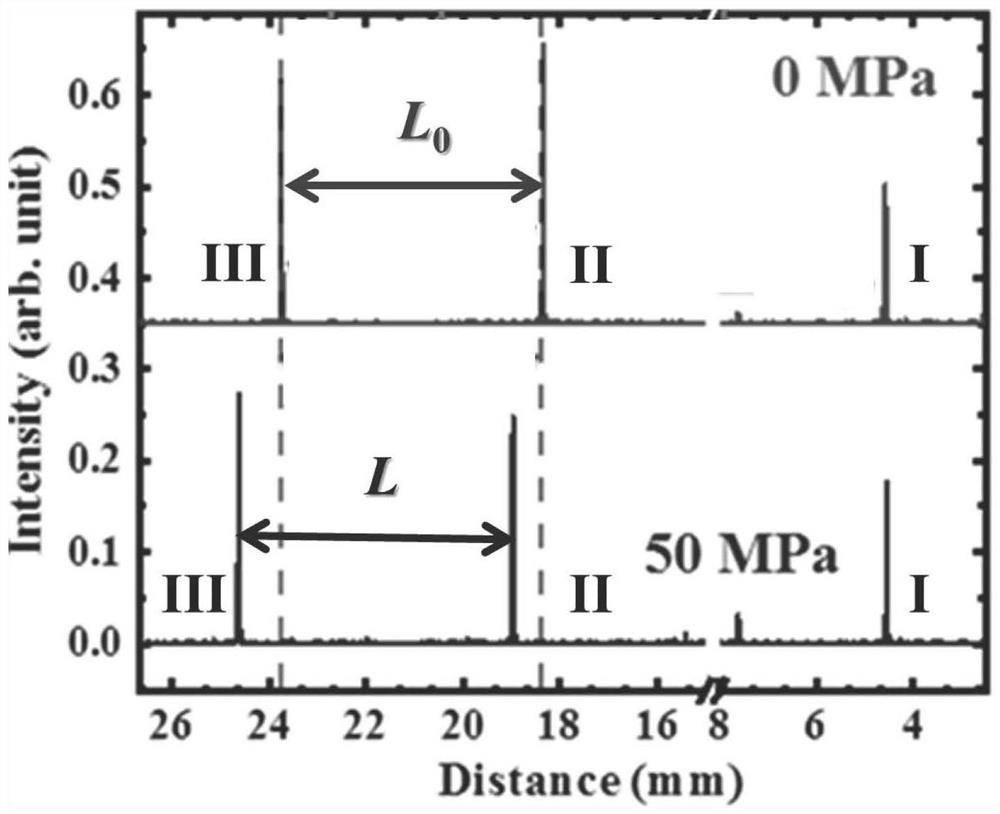

[0033] Such as Figure 4 The measurement results of the refractive index of hydrogen-deuterium mixed gas in the pressure range of 0-60MPa are given, and the detection laser wavelength is λ=1500nm. Before the target chamber is inflated, we reduce the air pressure of the target chamber to 10 through a vacuum pump. -2 Pa, then measure the length L of the sample cavity in the vacuum state between W1 and W2 corresponding to the i-th probe by OFDI 0i . After the air pressure of the sample to be tested is pressurized by the booster pump and enters the target chamber, it is left to stand for about 5 minutes. After the pressure and temperature of the gas sample reach equilibrium, the pressure P of the sample is read through the high pressure sensor, and the temperature T of the sample is read through the thermocouple. , and finally measure the thickness L of the sample cavity between W1 and W2 corresponding to the i-th probe under high-pressure inflation state by OFDI i . According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com