Fracturing manifold quick connecting device

A fracturing pipe and oil supply device technology, applied in the field of fracturing, can solve the problems of difficult assembly, poor adaptability, reverse flow of fracturing fluid, etc., so as to reduce the difficulty of manual operation, reduce maintenance costs, and increase service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

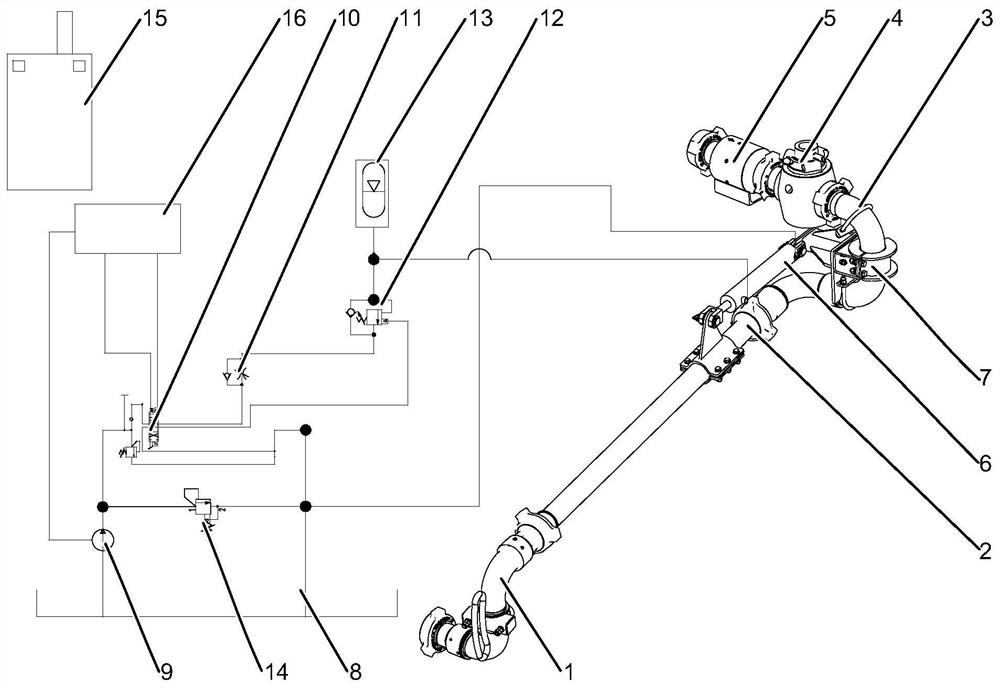

[0014] like figure 1 As shown, a fracturing manifold quick-connecting device includes a first swivel elbow 1, a straight pipe 2, a second swivel elbow 3, an oil cylinder 6, a support 7, a plug valve 4, a check valve 5, and a hydraulic system , the control unit, the first swivel elbow 1, the straight pipe 2, the second swivel elbow 3, the plug valve 4 and the check valve 5 are sequentially connected, and the fracturing fluid is sequentially passed through the first swivel elbow 1 by the fracturing equipment , straight pipe 2, second swivel elbow 3, plug valve 4 and check valve 5 are delivered to the manifold skid. The support 7 is fixedly connected to the second elbow 3, specifically, the second elbow 3 includes a first elbow and a second elbow and the first elbow and the second elbow are rotatably connected, The first elbow is also connected to the plug valve 4, the second elbow is also connected to the straight pipe 2, and the support 7 is fixedly connected to the first elbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com