Weaving method of bare spandex yarn plated flat knitted fabric and yarn feeding device of bare spandex yarn plated flat knitted fabric

A feeding device and knitted fabric technology, which is applied in the direction of weft knitting, knitting, textiles and papermaking, etc., can solve the problem of increasing the possibility of friction and adhesion between naked ammonia yarn and yarn guide device, and solve the problem of easy curling and detachment , Wide application prospects, guarantee the effect of cloth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

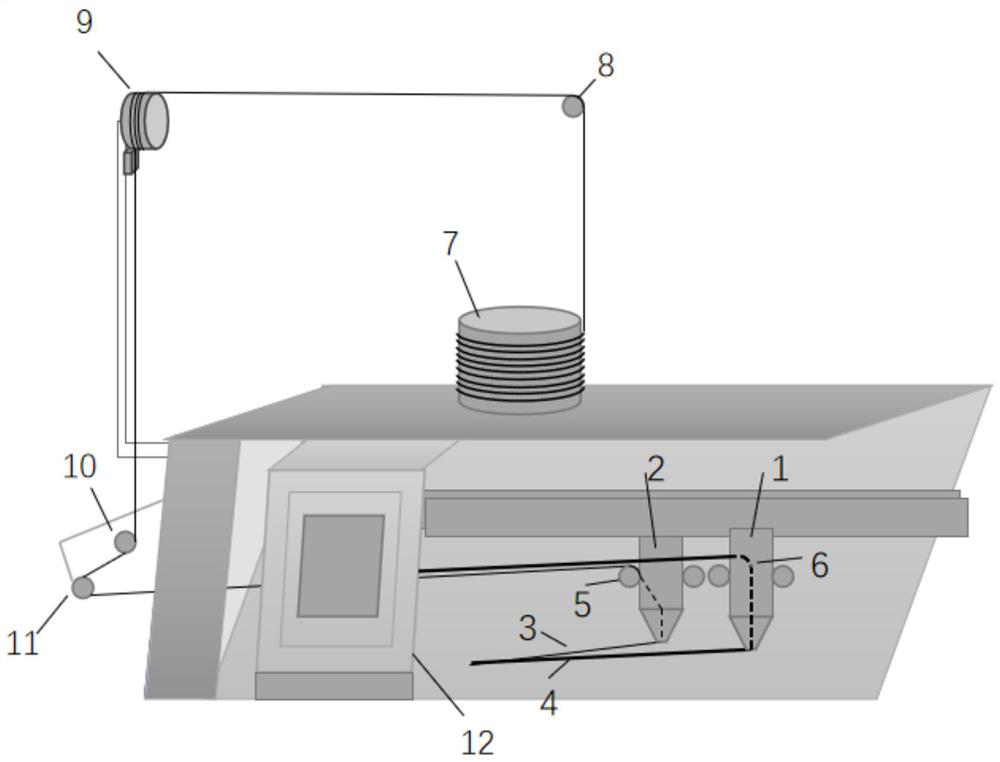

[0035] Such as figure 1 , this embodiment provides a yarn feeding device for naked ammonia silk plated flat knitted fabrics, including: a first yarn feeder 1, a second yarn feeder 2, naked ammonia silk 3, ordinary yarn 4, and a roller channel 5 , Yarn guide channel 6, naked ammonia yarn tube 7, yarn guide roller 8, constant tension yarn feeder 9, buffer roller 10, buffer arm 11, flat knitting machine head 12, flat knitting machine;

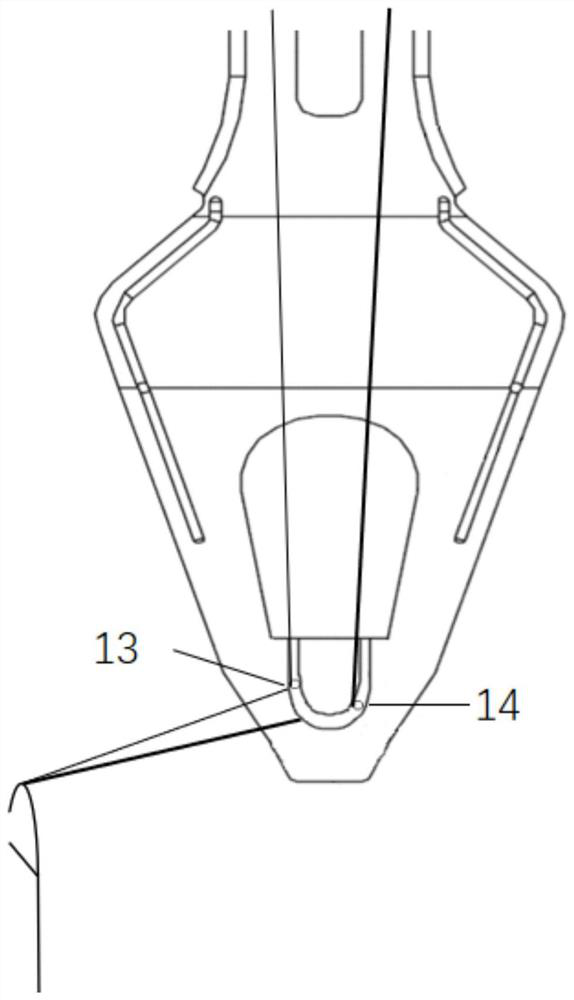

[0036] There is a yarn guide roller on both sides of the upper part of the first yarn feeder 1, a yarn guide porcelain eye is respectively arranged on both sides of the middle part of the first yarn feeder 1, and the bottom of the first yarn feeder 1 is a yarn feeding hole , the first yarn feeder 1 and the second yarn feeder 2 have the same structure, the first yarn feeder 1 is used to feed ordinary yarn 4, and the second yarn feeder 2 is used to feed naked ammonia silk 3, so The first yarn feeder 1 is set on one side of the second yarn feeder 2...

Embodiment 2

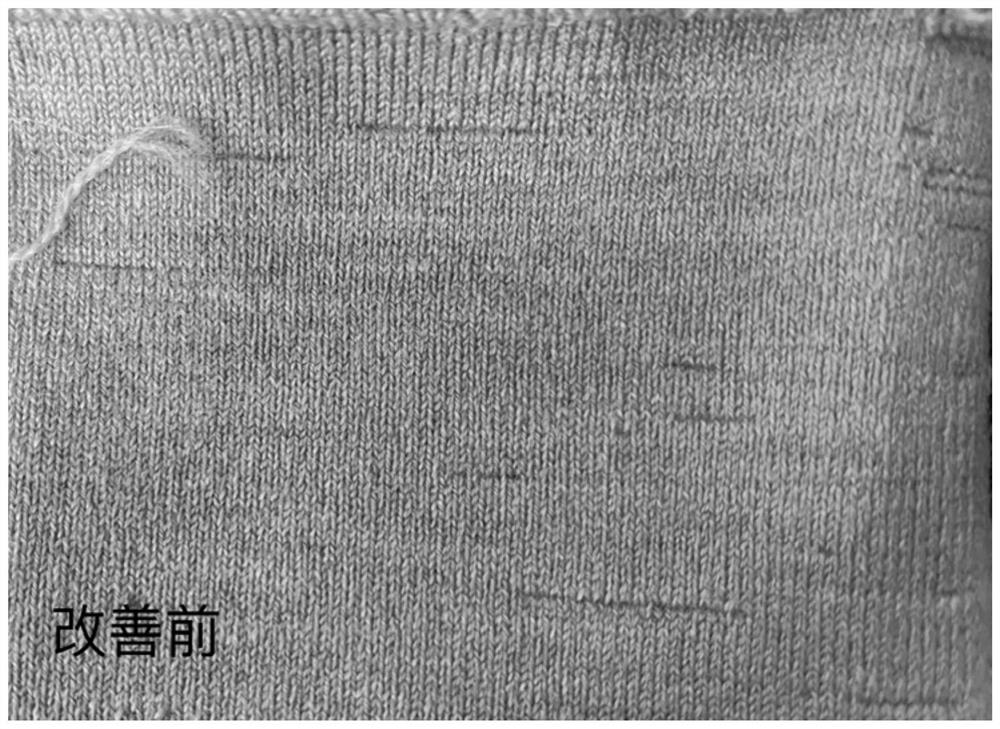

[0049] This embodiment provides a weaving method of naked ammonia silk plated flat knitting fabric, which is to realize constant tension yarn feeding of naked ammonia silk when the machine head is running and knitting, so as to ensure the smoothness of the cloth surface. The methods include:

[0050] Step 1: the naked ammonia yarn 3 enters the constant tension yarn feeder 9 from the naked ammonia yarn drum 7 through the yarn guide roller 8, and after the tension balance is performed by the constant tension yarn feeder 9 (the constant tension yarn feeder itself has a yarn storage function, it starts When a certain balance tension is reached, when the yarn feeder detects that the tension becomes larger, increase the amount of yarn feeding; when it detects that the tension is too small, stop yarn feeding, and continue feeding until the yarn tension reaches the set value), and then pass in The buffer roller 10 and the buffer arm 11 control the margin of the naked ammonia silk thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com