Automatic bundling equipment for plastic bag production

An automatic strapping and plastic bag technology, which is applied to strapping materials, strapping machine parts, paper product packaging, etc., can solve problems such as low efficiency of strapping machines, and achieve the effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

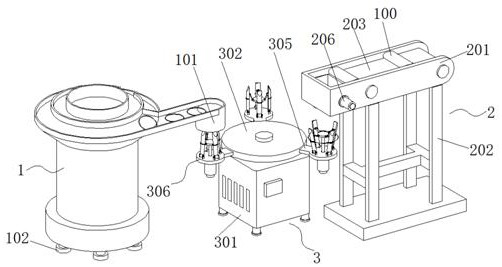

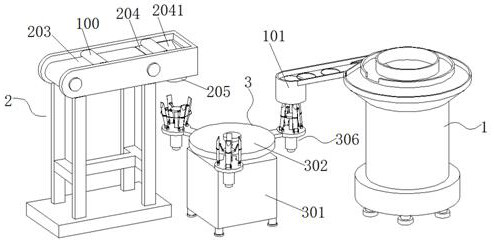

[0038] Embodiment 1 has introduced a kind of automatic strapping equipment for plastic bag production, with reference to attached figure 1 And attached figure 2 , its main structure includes a rubber ring vibrating plate 1, a plastic bag unloading mechanism 2 and a strapping device 3. Wherein the binding mechanism 3 is arranged between the rubber ring vibrating plate 1 and the plastic bag unloading mechanism 2 .

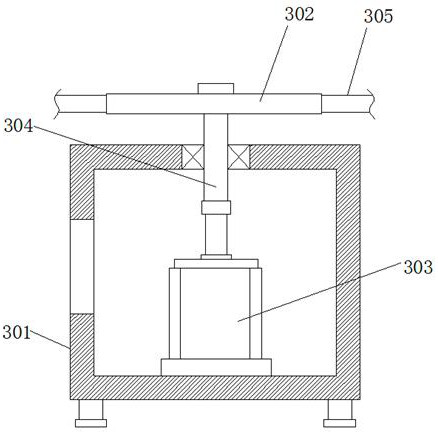

[0039] Reference attached image 3 , its strapping device includes a chassis 301, a turntable 302 and a stepping motor 303. A PLC (not marked in the figure) is provided on the outer side of the case 301, wherein the PLC can be selected from Mitsubishi's FX1N-24MT-001 model, and its stepping motor can be selected from a 60BYG350DL-0451 model. During the specific setting, the stepping motor 303 is arranged inside the cabinet 1, and a heat dissipation port (not shown in the figure) is provided on the side of the cabinet 1, and the upper end of the output shaft of th...

Embodiment 2

[0044] Embodiment 2 is to add a finished product unloading mechanism after binding on the basis of embodiment 1. For details, refer to the attached Figure 8 And attached Figure 9 .

[0045] Embodiment 2 does not repeat the description of the same part as Embodiment 1, and the difference is that, with reference to the attached Figure 8 , also be provided with finished product unloading mechanism 4 on the side of binding device 3, can be arranged on the downstream position of plastic bag unloading mechanism 2 with finished product unloading mechanism 4 during specific setting. Among them, the finished product blanking mechanism 4 includes mechanical grippers 401, lifting hydraulic cylinders 402, rotating columns 403, rotating drums 404 and servo motors 405, wherein the servo motors 405 can be selected from servo motors with a model number of 110MB060D-001000. Bearings 4041 are arranged at the upper and lower ends of the inner cavity, and the rotating column 403 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com