Preparation method of color-changing microcapsule capable of being applied to textile and color-changing microcapsule

A microcapsule and textile technology, which is applied in the direction of microcapsule preparation, microsphere preparation, color-changing fluorescent materials, etc., can solve the problems of insufficient discoloration sensitivity and failure to meet the requirements, and achieve high temperature sensitivity, reduce damage, and high conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

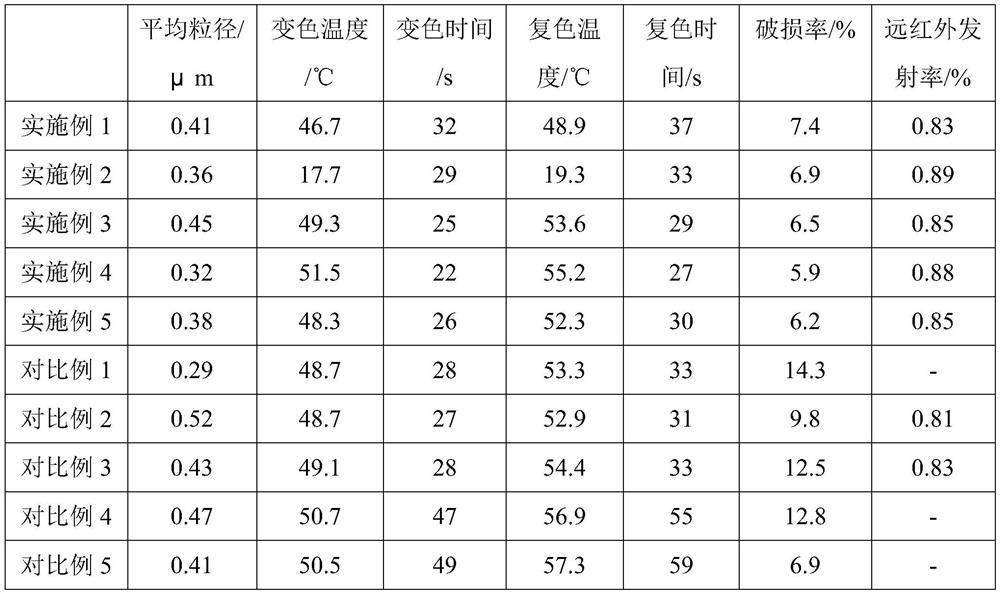

Examples

Embodiment 1

[0027] 1 part by weight of crystal violet lactone, 3 parts by weight of bisphenol A, 30 parts by weight of n-tetradecyl alcohol, 2.8 parts by weight of butyl methacrylate, 0.2 parts by weight of tripropylene glycol diacrylate and 1 part by weight of 3-(formyl 2.5 parts by weight of OP-10 and 0.5 parts of sodium dodecylbenzenesulfonate were added, stirred and dispersed at a constant temperature to obtain dispersion 1; Under high-speed stirring, add 80 parts by weight of water to the dispersion liquid 1, and stir evenly to obtain emulsion 1; Hours, suction filtration, washing, drying, to obtain color-changing microcapsules 1.

Embodiment 2

[0029] 1 part by weight of 2-anilino-6-diethylaminofluorane, 4 parts by weight of bisphenol F, 38 parts by weight of n-stearyl alcohol, 4.5 parts by weight of styrene, 0.5 parts by weight of trivinylbenzene and 3 parts by weight of 3 -(Methacryloyloxy)propyltriethoxysilane-treated nano-tourmaline mixed, heated and melted, added 6 parts by weight of OP-10 and 1 part by weight of sodium lauryl sulfate, stirred at a constant temperature to disperse evenly, and obtained a dispersed Liquid 2; under high-speed stirring, add 110 parts by weight of water to the dispersion liquid 2, and stir evenly to obtain emulsion 2; add 2.5 parts by weight of ammonium persulfate to the emulsion 2, heat up to 35°C, slowly add 1 part by weight of sodium sulfite, and react After 2.5 hours, filter, wash, and dry to obtain color-changing microcapsules 2 .

Embodiment 3

[0031] 1 part by weight of crystal violet lactone, 5 parts by weight of 1,5-dihydroxynaphthalene, 47 parts by weight of n-octadecane, 6.6 parts by weight of isooctyl methacrylate, 0.4 parts by weight of pentaerythritol tetraacrylate and 6 parts by weight of vinyl Mix the nano-tourmaline treated with trimethoxysilane, heat and melt, add 8 parts by weight of AEO-10 and 2 parts by weight of sodium dodecylbenzenesulfonate, stir and disperse evenly at a constant temperature, and obtain dispersion 3; Add 130 parts by weight of water to liquid 3, stir evenly to obtain emulsion 3; add 4 parts by weight of water-soluble azo free radical initiator AIBI to emulsion 3, heat up to 60°C and react for 6 hours, suction filter, wash, dry, Obtain color-changing microcapsules 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com