Dissolved oxygen sensor calibration device and dissolved oxygen sensor calibration method

A technology of dissolved oxygen sensor and calibration device, applied in the field of measurement, can solve the problems of low calibration efficiency, cumbersome operation, long time-consuming calibration, etc., to avoid injury and secondary pollution, simplify the proportioning process, and save the calibration time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

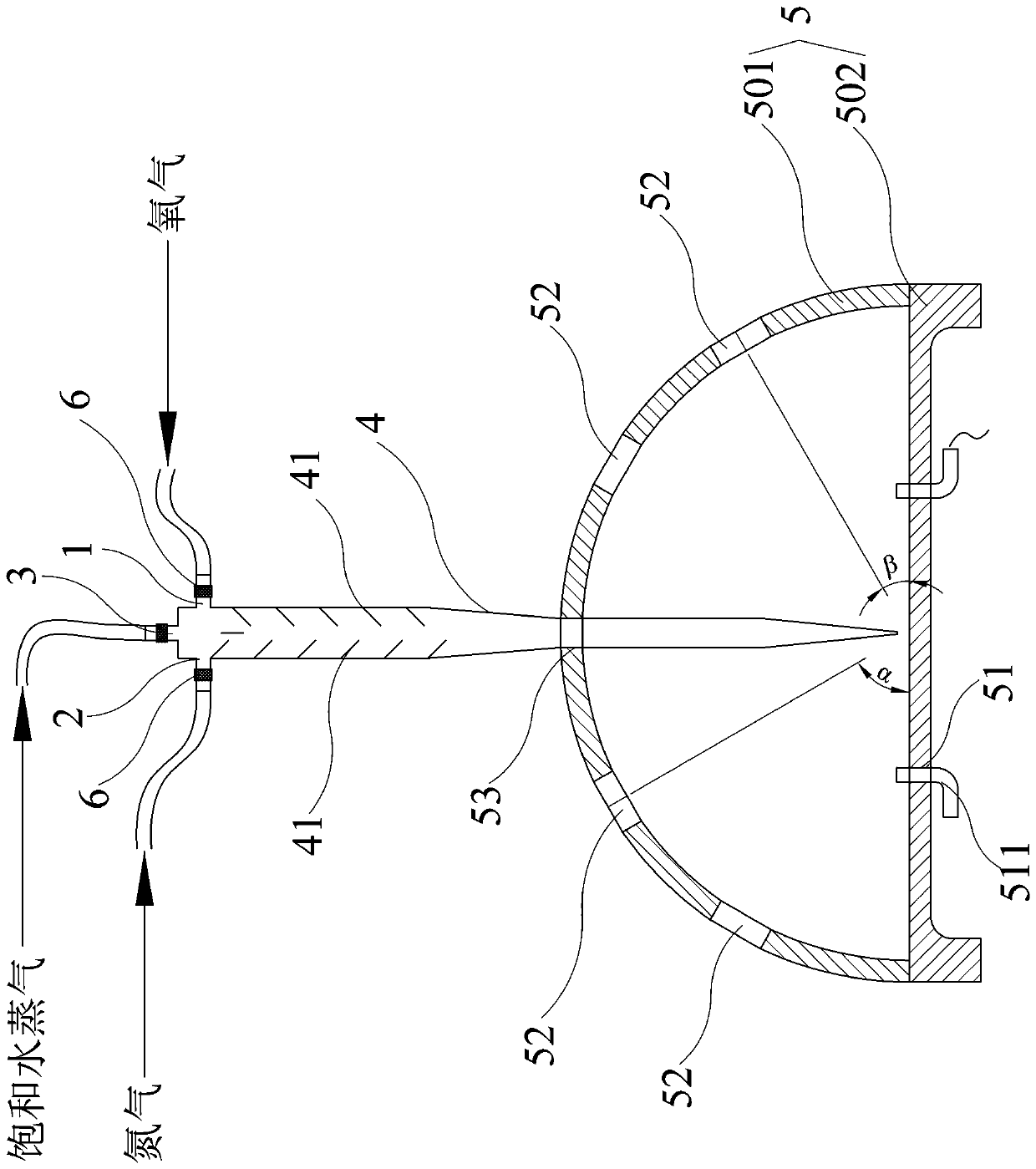

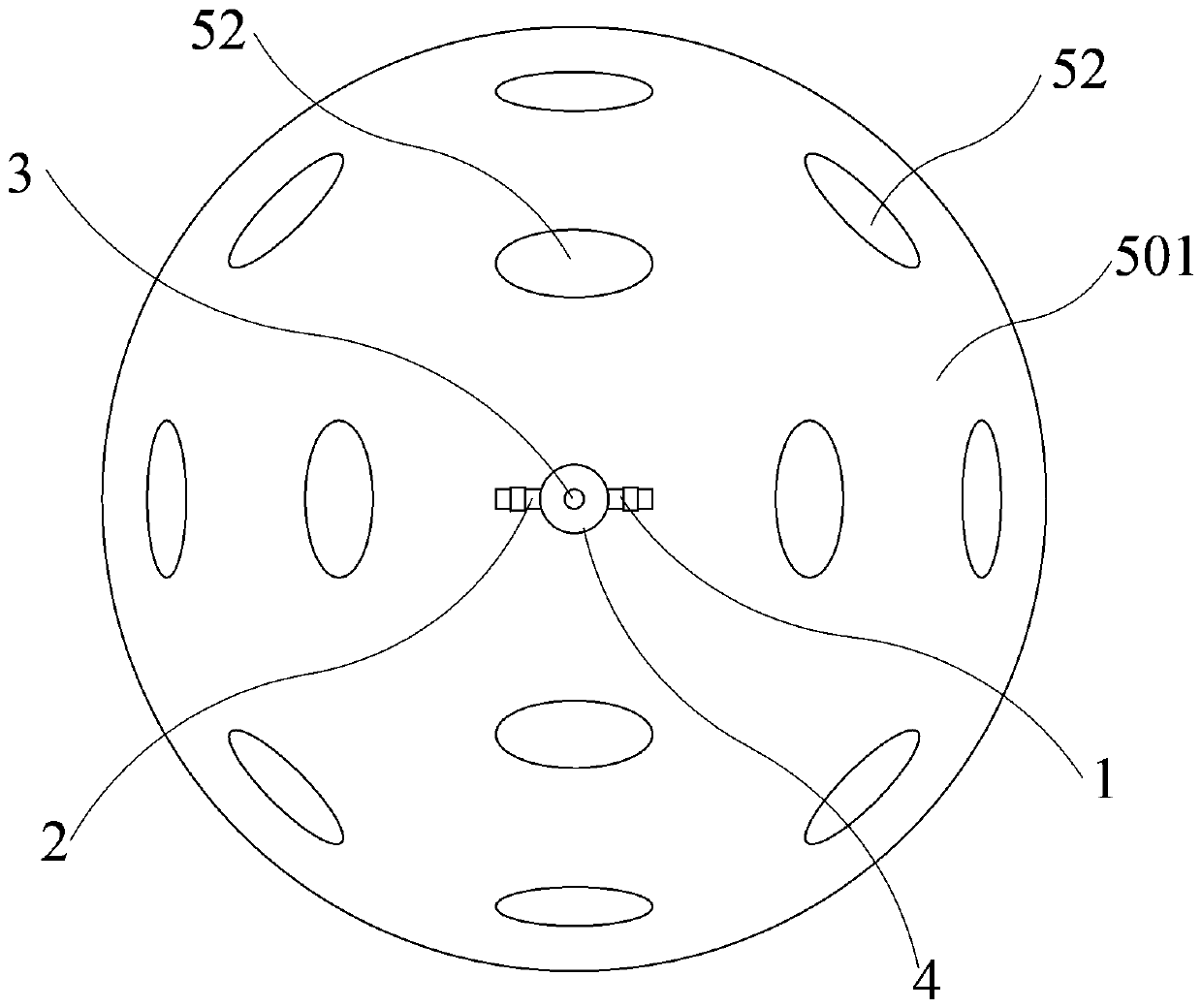

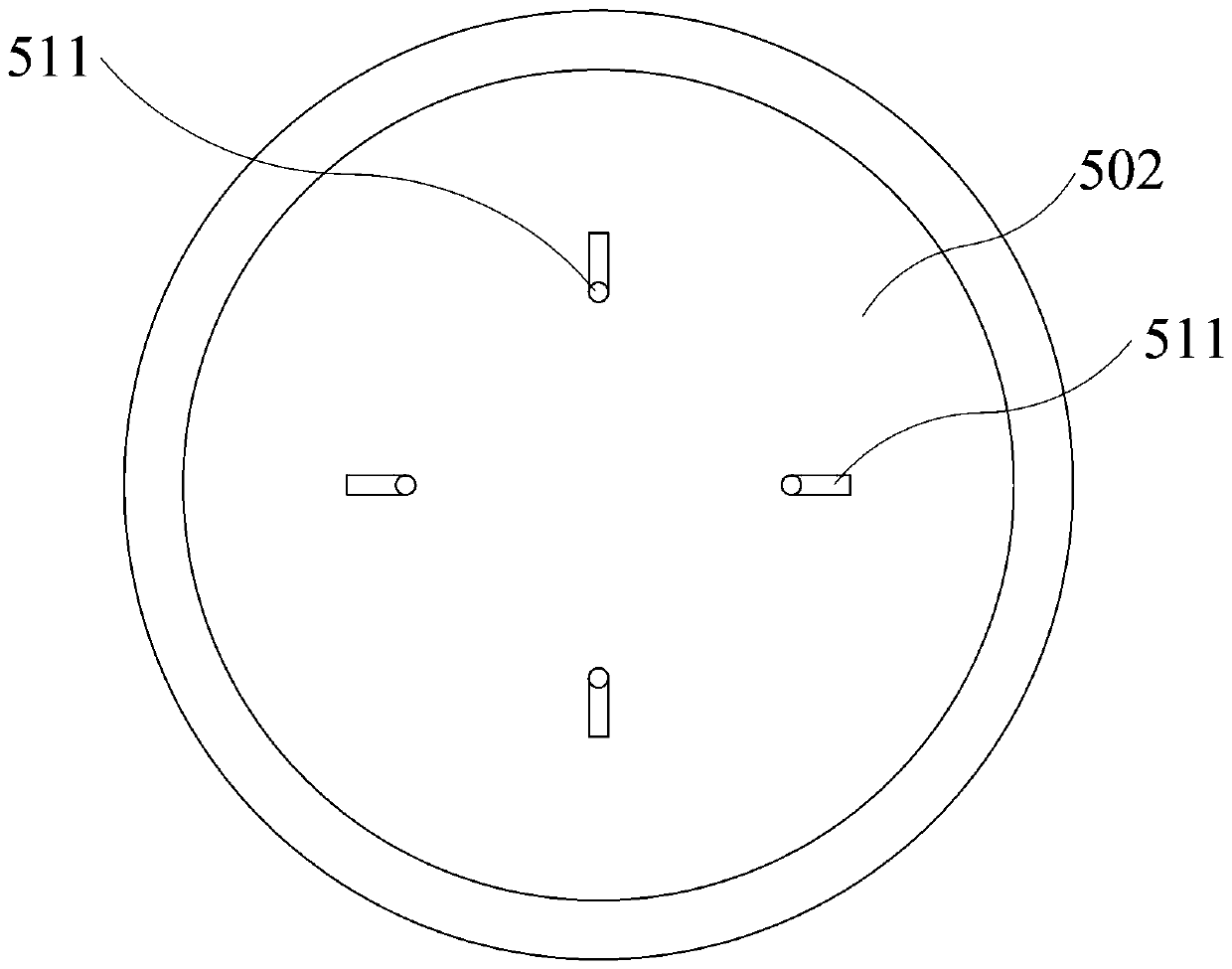

[0041] Such as Figure 1 to Figure 3 As shown, the present invention discloses a dissolved oxygen sensor calibration device, which includes an oxygen input interface 1, a nitrogen input interface 2, a saturated water vapor input interface 3, a gas mixing pipeline 4 and a calibration chamber 5; wherein the oxygen input interface 1 , the nitrogen input interface 2 and the saturated water vapor input interface 3 are connected to the gas mixing pipeline 4 and communicate with the inner chamber of the gas mixing pipeline 4; the gas mixing pipeline 4 is connected with the calibration chamber 5 and the inner cavity of the gas mixing pipeline 4 is connected with The inner cavity of the calibration chamber 5 communicates; the calibration chamber 5 is provided with a liquid seal 51 communicating with the inner cavity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com