Columnar joint sample pasting device

A technology of patch device and columnar joint, applied in the field of columnar joint sample patch device, can solve problems such as affecting the test accuracy, and achieve the effect of ensuring reliability and accuracy and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

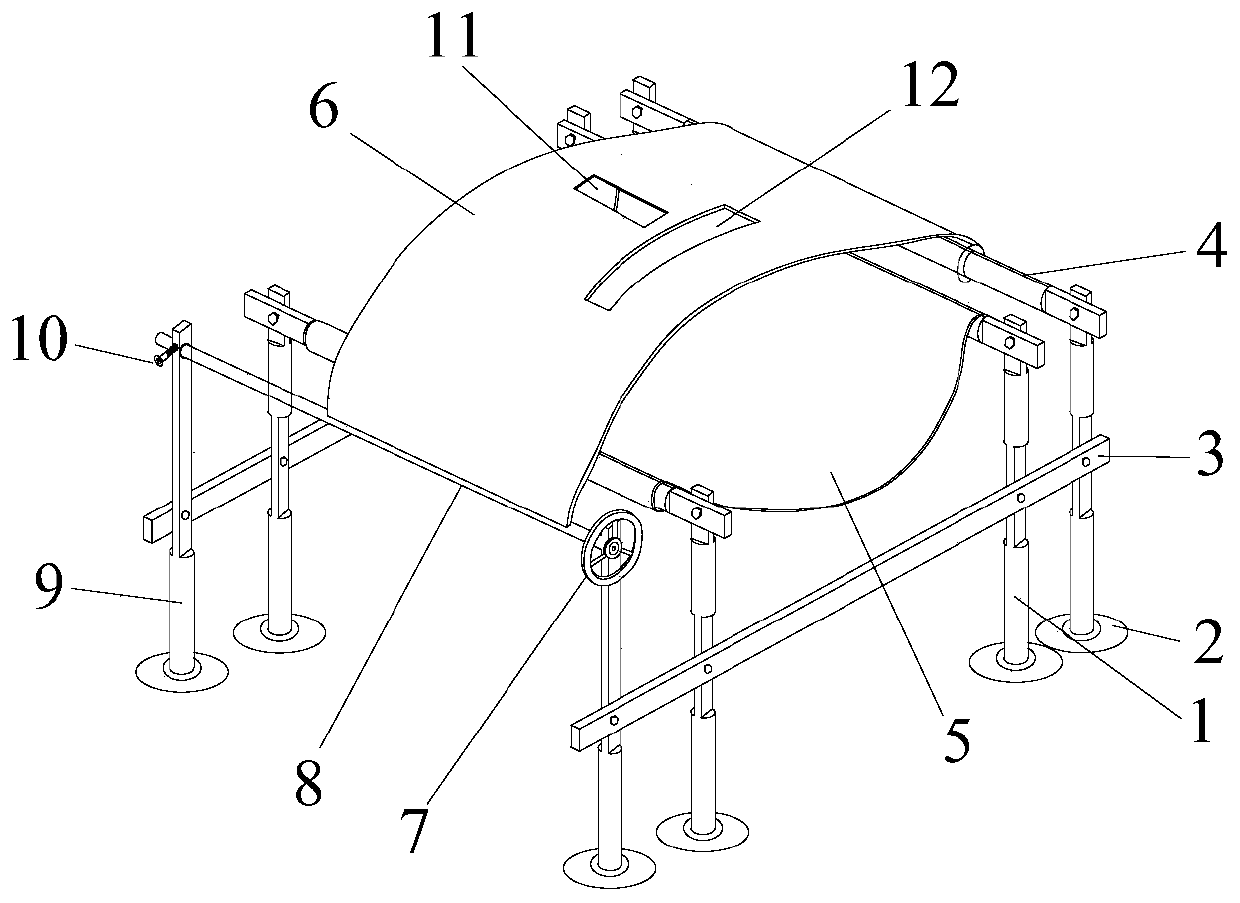

[0014] Such as figure 1 As shown, the bracket and sample constraining structure of the present invention, the bracket includes two groups of symmetrically distributed first lower brackets 1 and second lower brackets 9, wherein the first lower bracket 1 is located inside the second lower bracket 9, and the left side is located The top of one group of second lower brackets 9 is fixed with adjusting rod 8, the top of another group of second lower brackets 9 is connected with upper bracket 4, and the tops of two groups of first lower brackets 1 are connected with upper bracket 4, upper bracket 4 All are detachably connected by bolts. A lower restraint rubber plate 5 is arranged between the two groups of upper supports 4 at the top of the first lower support 1, and an upper restraint rubber plate 6 is arranged between the upper support 4 and the adjusting rod 8 at the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com