Device and method for passivating heavy metals by fermenting and composting field livestock and poultry breeding wastes in cold regions

A technology for livestock and poultry breeding and waste, which is applied in the field of field livestock and poultry breeding waste fermentation and composting passivation heavy metal devices in cold regions, can solve the problems of high cost, inability to passivate heavy metals, and difficulty in raising the temperature of aerobic composting in the field. Low cost and short composting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

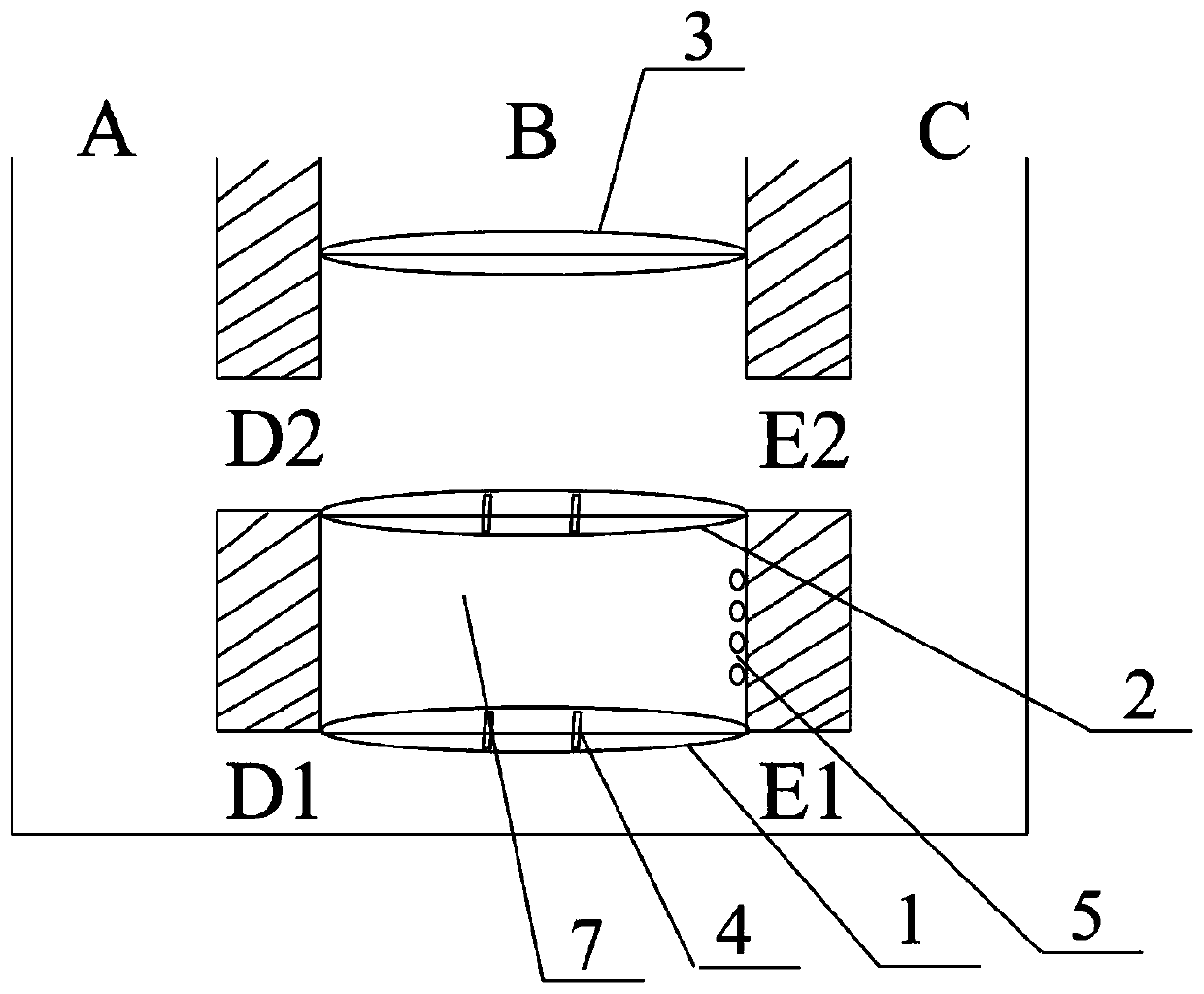

[0026] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment comprises fermenting vat 7, lower disc 1, upper disc 2, cover plate 3 and hinge 4, the diameter of the upper opening of fermenting vat 7 is greater than the diameter of the lower opening, that is, the diameter of the upper opening is 1.8m~ 2.2m, the diameter of the lower opening is 1.6m~2m, the height of the fermenter 7 is 1m, several round holes 5 are arranged on the barrel wall of the fermenter 7, the round holes 5 are used for ventilation, and the upper circular plate 2 consists of two Composed of semicircles and connected by hinge 4, upper circular plate 2 is arranged at the upper port of fermentation tank 7, upper circular plate 2 and fermentation tank 7 are connected by iron wire, lower circular plate 1 is composed of two semicircles and connected by hinge 4, and the lower circular plate 2 is connected by hinge 4. The circular plate 1 is arranged at the lower port of the f...

specific Embodiment approach 2

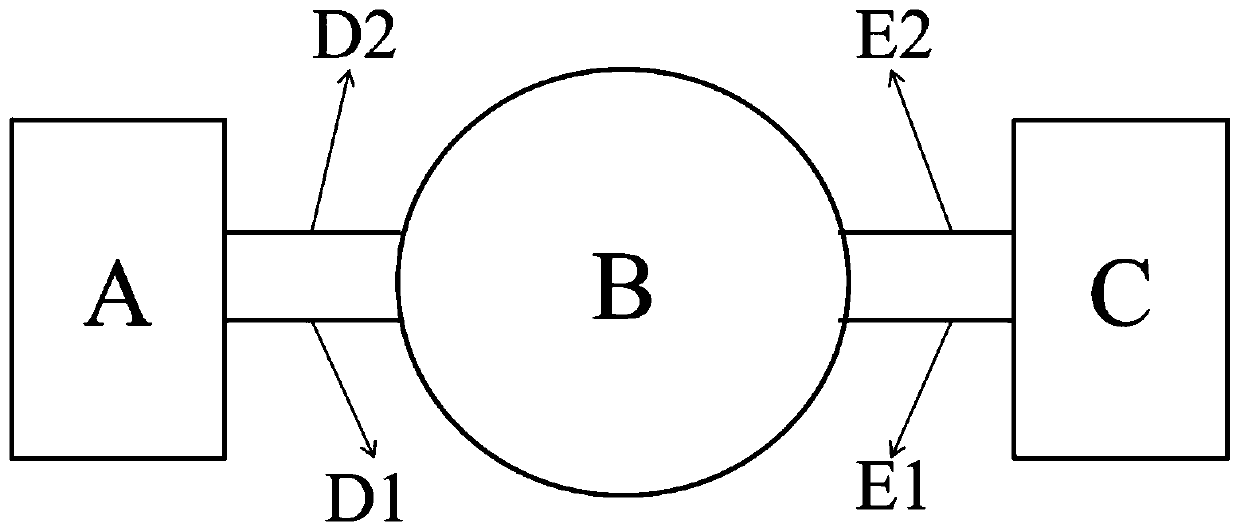

[0030] Specific implementation mode two: combination figure 1 and figure 2 Describe this implementation mode, this implementation mode is realized through the following steps:

[0031] Step 1. Excavate the fermentation port B: excavate the fermentation port B in the field. The fermentation port B is cylindrical. The diameter of the upper end of the fermentation port B is larger than the diameter of the lower end, that is, the diameter of the upper end is 1.8m~2.2m, and the diameter of the lower end is 1.6m~2m. The height of fermentation port B is 2.4m;

[0032] Step 2. Excavate fuel channel A and smoke outlet channel C: Excavate fuel channel A and smoke outlet channel C on the left and right sides of fermentation port B respectively. The distance between fuel channel A, smoke outlet channel C and fermentation port B is 0.5m. The shape of the fuel channel A is a cuboid with a length of 0.5m, a width of 0.3m and a height of 2.4m. The shape of the smoke outlet channel C is a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com