Granulated feed conveying device

A technology of conveying device and pellet feed, which is applied in conveyors, transportation and packaging, loading/unloading, etc., can solve the problems of increased energy consumption of equipment by throwing force, scattered distance of dust-prone materials, and time-consuming cleaning, etc., and achieves high flexibility. , to avoid the effect of throwing force and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

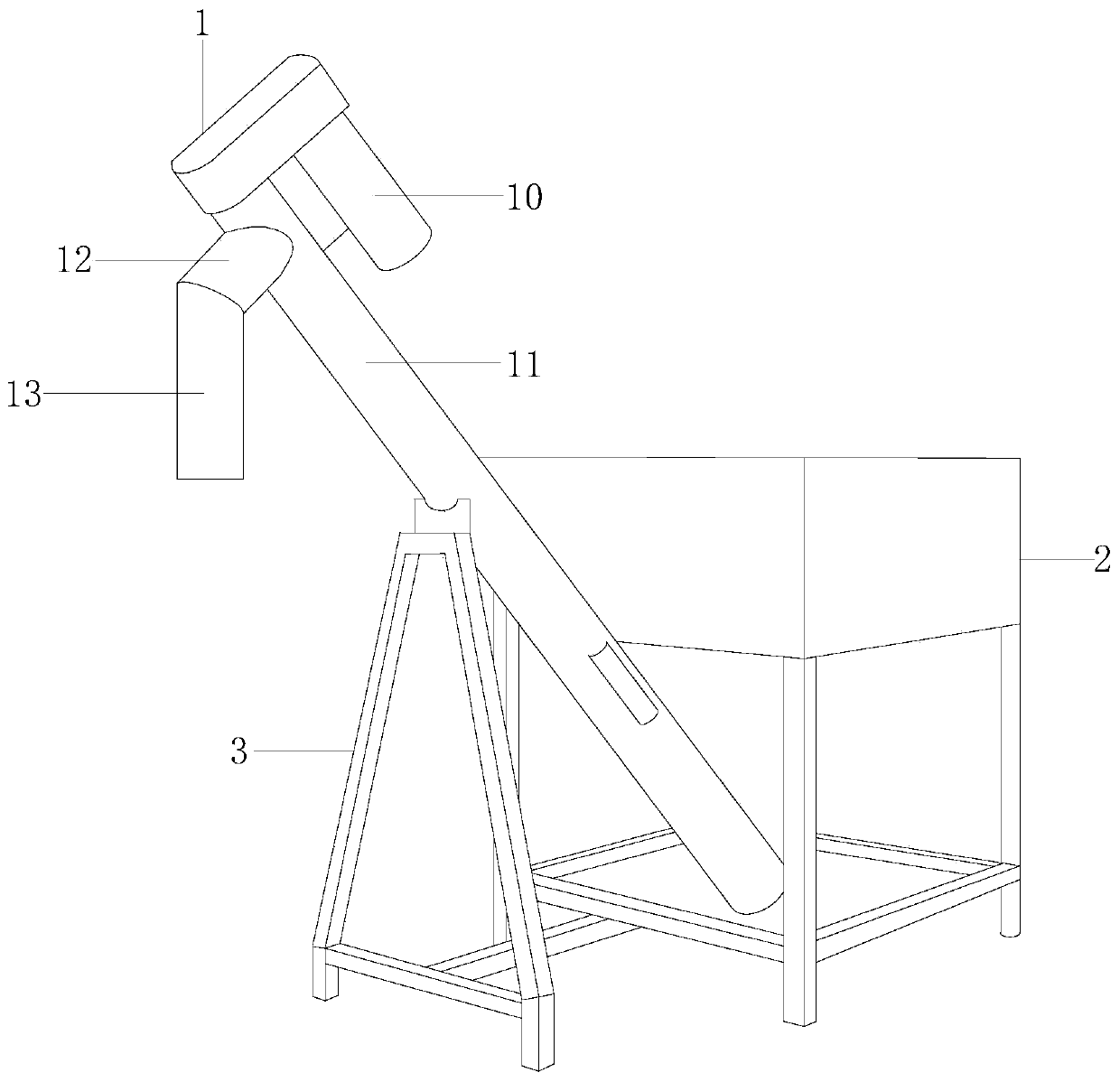

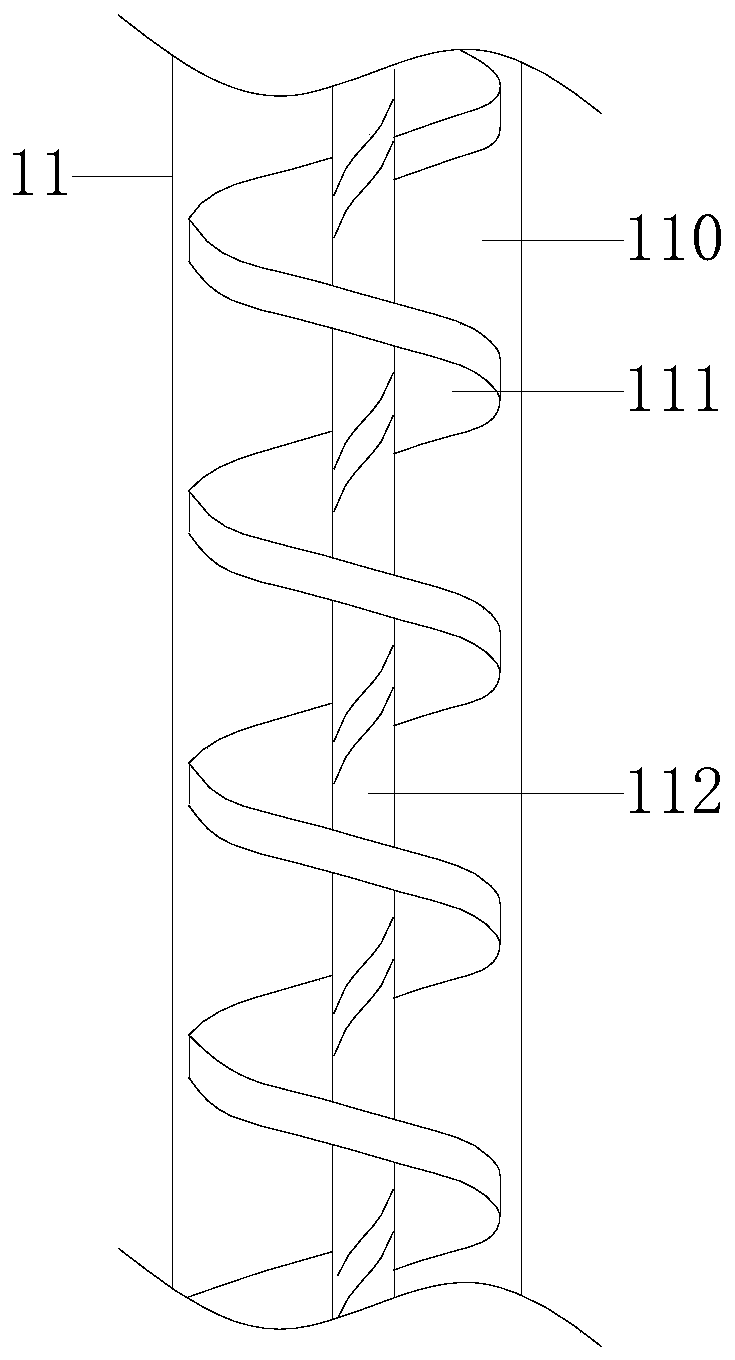

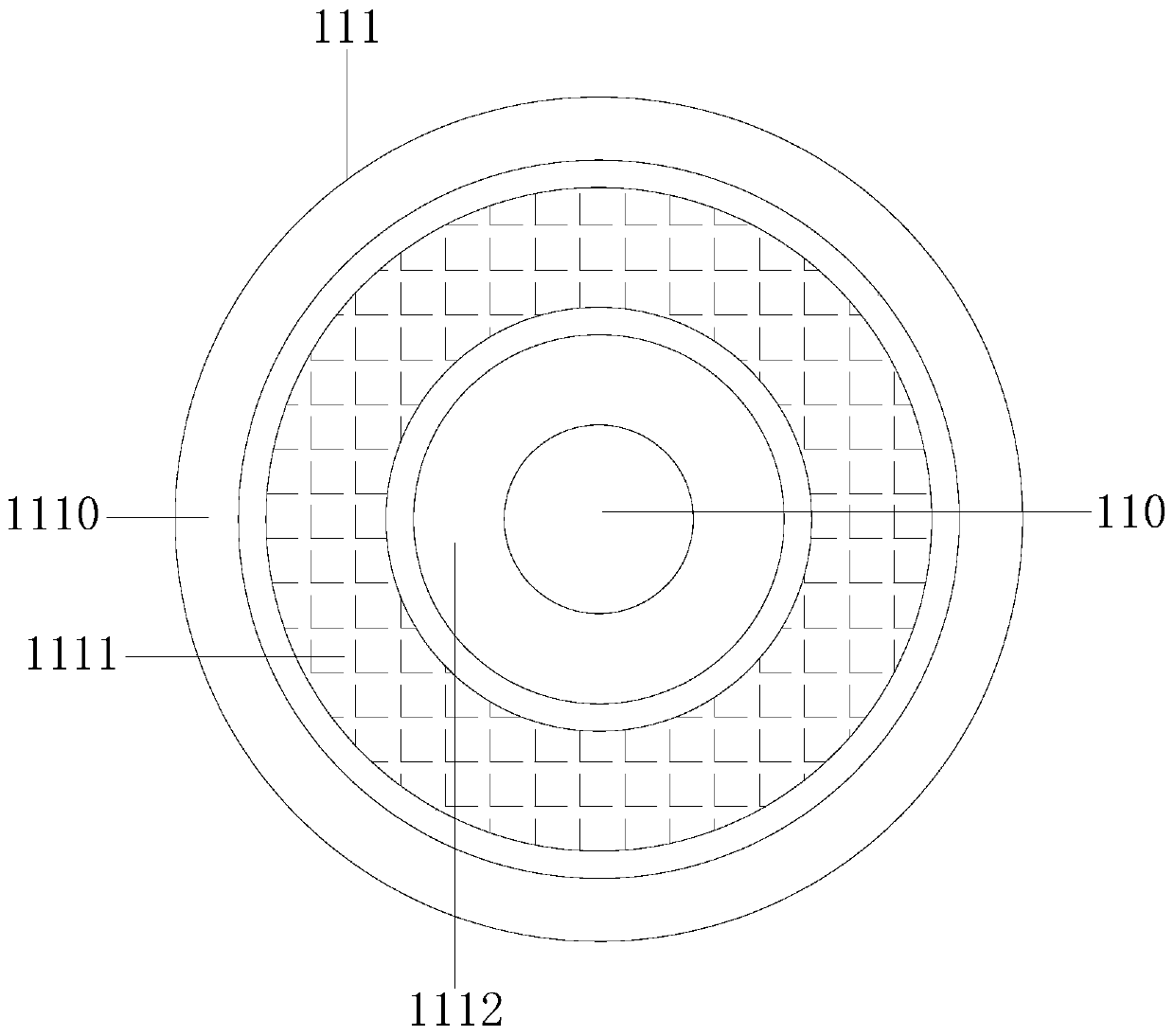

[0026] Example 1 see Figure 1-5 , the present invention provides a technical solution for a granular feed conveying device: its structure includes a feeding structure 1, a charging frame 2, and a support frame 3, the right end of the feeding structure 1 is installed and connected to the charging frame 2, and the charging frame 2. The left end is welded with the support frame 3, and the conveying structure 1 is arranged on the upper end of the support frame 3. The conveying structure 1 is composed of a motor 10, a conveying cylinder 11, a rotating material cylinder 12, and a blanking cylinder 13. The motor 10 It is installed and connected with the upper end of the conveying cylinder 11. The left and right ends of the rotating material cylinder 12 are welded with the conveying cylinder 11 and the blanking cylinder 13. The conveying cylinder 11 includes a conveying cylinder body 110, a conveying screw 111, and a conveying shaft 112. The conveying screw 111 and the conveying shaf...

Embodiment 2

[0028] Example 2 see Figure 6 , 7, the present invention provides a technical solution for a granular feed conveying device: the structure of the blanking cylinder 13 includes a thread groove 130, a lifter 131, a blanking cylinder body 132, and a turning structure 133, and the inner ring of the blanking cylinder body 132 There is a thread groove 130 on the side, and the thread groove 130 plays the role of material buffering. The lifter 131 is installed on the blanking barrel body 132 and the two form an integrated structure. The lifter 131 is used to adjust the drop. The height of the barrel 13 improves the flexibility of discharging. The bottom of the blanking barrel body 132 is installed and connected with the turning structure 133. The turning structure 133 includes a blanking tray 1330 and a main body turning tray 1331. The blanking tray 1330 is installed and connected to the upper end of the main body turning plate 1331, the blanking plate 1330 is embedded with a blanki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com