Auxiliary tooth type harmonic induction excitation motor

A technology of excitation motor and auxiliary teeth, applied in the direction of magnetic circuit, electric components, electrical components, etc., can solve the problem of large volume of the motor system, and achieve the effect of increasing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

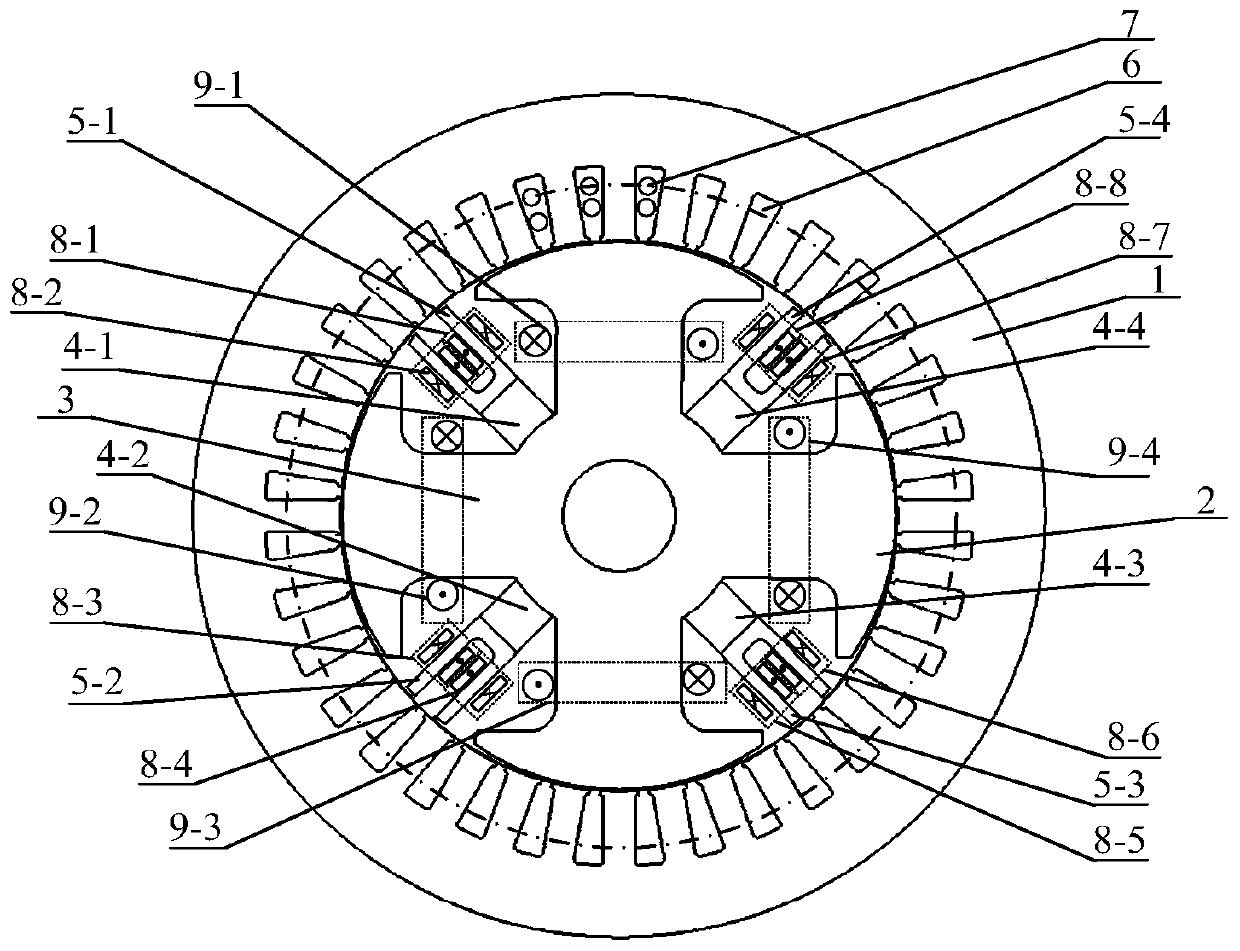

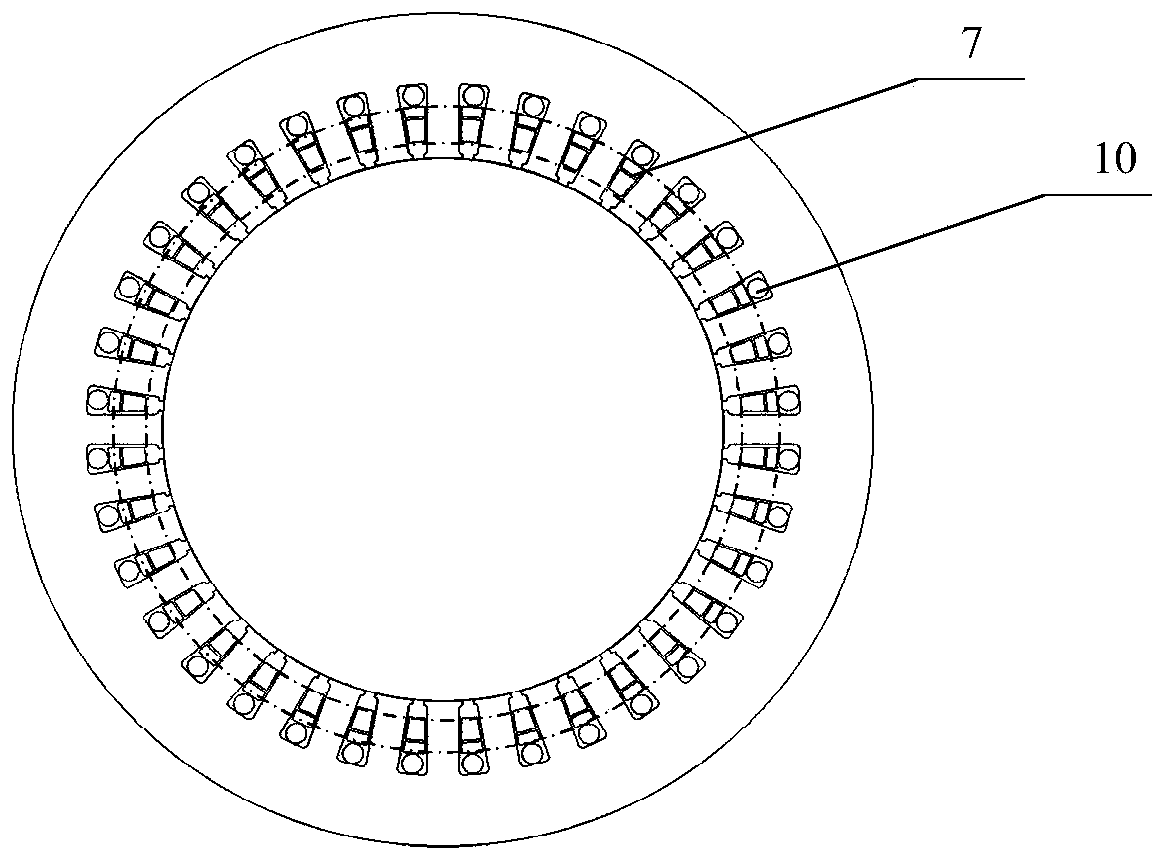

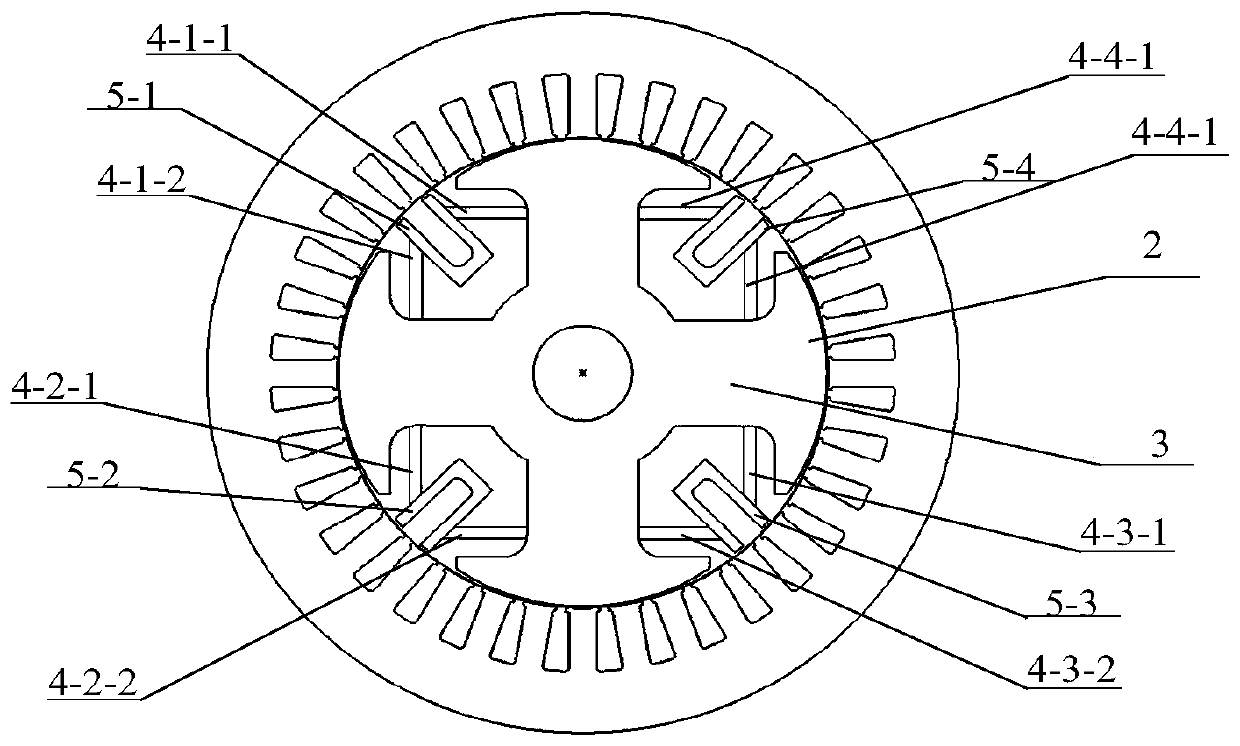

[0024] The present invention designs an auxiliary tooth type harmonic induction excitation motor, such as figure 1 As shown, taking the stator with 36 slots and the rotor with 4 poles as an example, auxiliary rotor cores 5-1, 5-2, 5-3, and 5-4 are installed on the rotor core 2, and each auxiliary rotor core is U-shaped. (It can also be set as a semicircle, etc.), the axial length of the auxiliary rotor core and the axial length of the rotor core 2 can be completely equal or not equal. The linearization compensation method of the bridge switch in the auxiliary rotor core unbalanced bridge insulation monitoring circuit is connected to the rotor core 2 through non-magnetic connection units 4-1, 4-2, 4-3, 4-4. Auxiliary harmonic induction windings 8-1, 8-2, 8-3, 8-4, 8-5, 8-6, 8-7, 8-8 are wound on each auxiliary rotor iron core. The rotor te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com