Foam filling type vane rear edge bonding corner and preparation method

A technology of blade trailing edge and foam filling, which is applied to chemical instruments and methods, mechanical equipment, wind turbines that are consistent with the wind direction, etc. Avoid wrinkling or slumping, reduce mold time, and optimize the effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

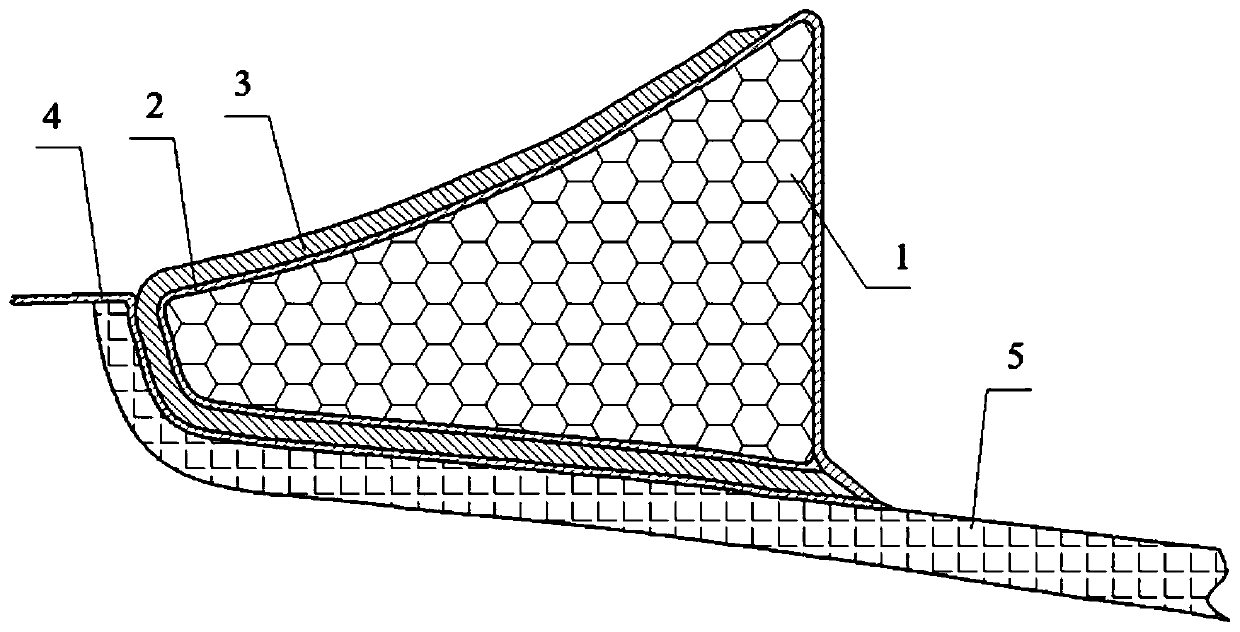

[0016] In order to better understand the purpose, structure and function of the present invention, a foam-filled blade trailing edge bonding angle and a preparation method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, it shows a foam-filled blade trailing edge bonding corner of the present invention, including foam, cladding layer 2, trailing edge bonding corner 3, and positioning layer 4. The air between the positioning layer 4, the FRP adhesive layer 3 and the cladding layer 2 is extracted by vacuuming auxiliary materials, so that the positioning layer 4, the FRP bonding layer 3 and the cladding layer 2 are flat and attached to the outside of the foam.

[0018] Further, it is preferable that the foam adopts polyurethane foam material to fill the bonding angle of the trailing edge of the blade in the form of foaming to fill up a certain cavity. In the present invention, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com