Dust removal method for heading face of mine

A technology for excavating working faces and mines, which is applied in dust prevention, mining equipment, earthwork drilling and mining, etc. It can solve the problems of easy generation of dust by wind flow, uneven wind pressure of air curtain, and poor sealing effect, so as to ensure the effect of suction and dust removal , Improve the amount of ventilation and dust removal, and ensure the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

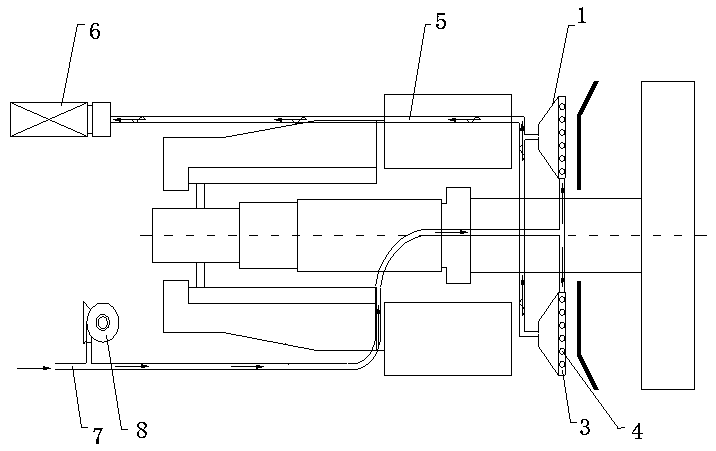

[0022] Such as figure 1 , the present invention proposes a kind of mine excavation working face dedusting method, comprises the following steps:

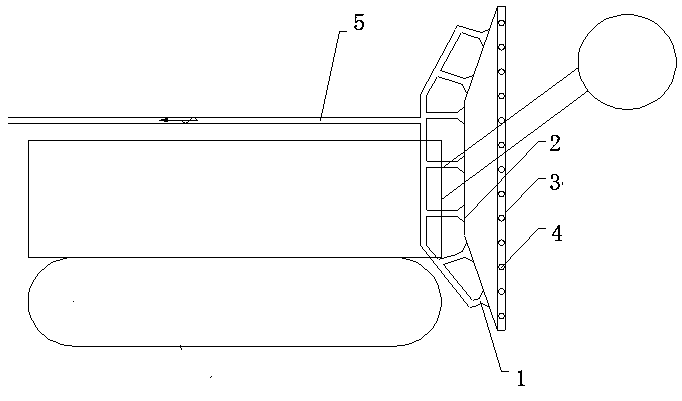

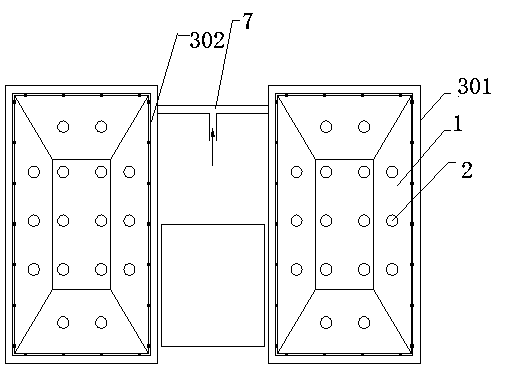

[0023] S1. Two conical wind collecting plates 1 are symmetrically arranged on the left and right sides of the front of the main shaft of the roadheader, and the opening of the conical wind collecting plates 1 faces the excavation side; the inner wall of each of the conical wind collecting plates 1 A plurality of air-collecting outlets 2 for suction are uniformly arranged on the upper surface; the air-collecting outlets 2 are connected to negative pressure dust removal fans 6 through rigid exhaust pipes 5; an outlet is fixed on the outer wall of each conical air-collecting plate 1. The wind frame 3; the air outlet frame 3 is connected to the compressor 8 through the air inlet hose 7; the two air outlet frames 3 are symmetrically arranged on the left and right sides of the front of the main shaft of the roadheader; the outer periphery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com