A medium-strength stress-corrosion-resistant aluminum-based material and its preparation method

An aluminum-based material and stress-resistant technology, applied in the field of metal materials, can solve the problems of neglecting stress corrosion resistance, low strength and rigidity, and difficult to meet the needs of high-strength and high-rigidity lightweight materials, and achieve good stress corrosion resistance. Effects of properties, high strength and elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

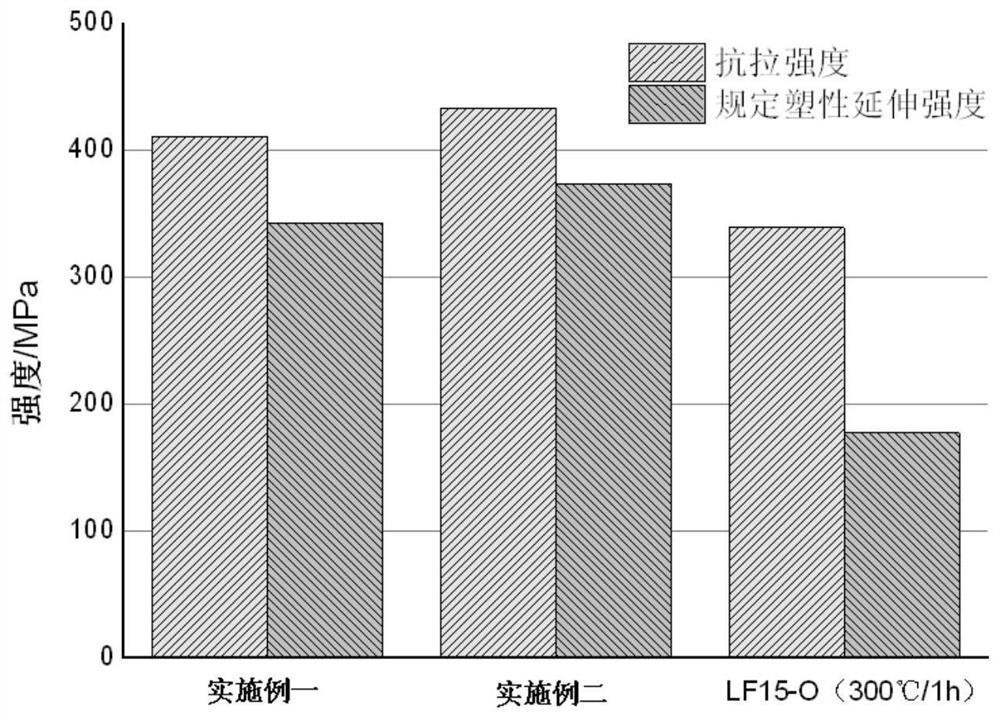

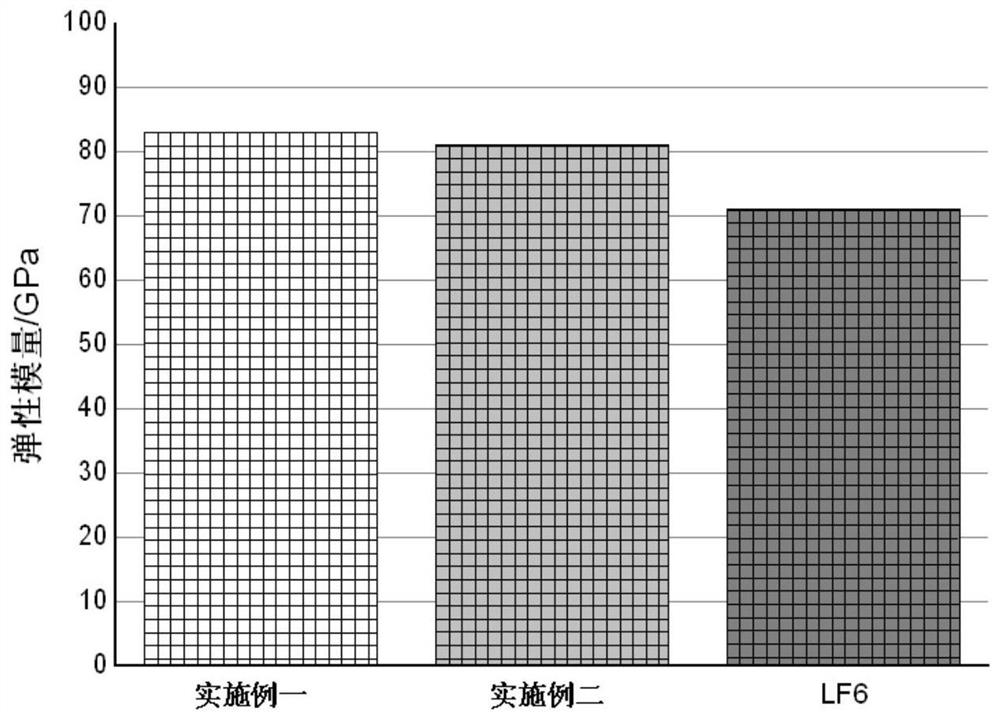

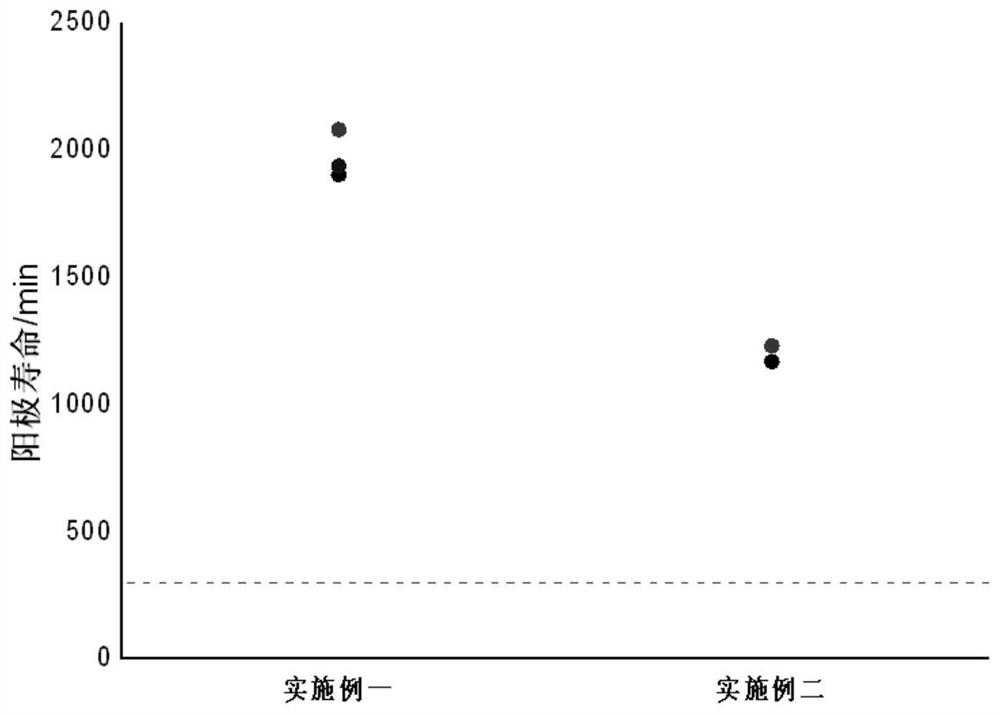

Embodiment 1

[0032] AlZn 3.9 Mg 1.9 mn 0.3 Zr 0.1 Cr 0.1 The alloy is used as the matrix, and silicon carbide with an average particle size of 5 μm is used as the reinforcing particles to prepare aluminum-based materials. The preparation process is as follows:

[0033] ① After weighing aluminum ingots, magnesium ingots, zinc ingots, and aluminum-based intermediate alloy ingots in proportion, alloy powders were prepared using a supersonic gas atomization furnace, and alloy fine powders of -200 mesh (≤71 μm) were obtained after sieving. The chemical composition of the alloy powder was tested, and the results are shown in Table 1.

[0034] ②Place silicon carbide particles with an average particle size of 5 μm at a temperature of 160°C for 7 hours, and then mix with AlZn 3.9 Mg 1.9 mn 0.3 Zr 0.1 Cr 0.1 Alloy fine powder is added in proportion to the mechanical mixer, the volume percentage of silicon carbide is 14% of the matrix, the rotation speed is 60r / min, and lasts for 120min. Pu...

Embodiment 2

[0049] AlZn 4.7 Mg 1.5 mn 0.4 Zr 0.1 Cu 0.2 The alloy is used as the matrix, and silicon carbide with an average particle size of 5 μm is used as the reinforcing particles to prepare aluminum-based materials. The preparation process is as follows:

[0050] ① After weighing aluminum ingots, magnesium ingots, zinc ingots, and aluminum-based intermediate alloy ingots in proportion, alloy powders were prepared using a supersonic gas atomization furnace, and alloy fine powders of -200 mesh (≤71 μm) were obtained after sieving. The chemical composition of the alloy powder was tested, and the results are shown in Table 4.

[0051] ② Put silicon carbide particles with an average particle size of 5 μm at a temperature of 170 ° C for 5 h, and then mix with AlZn 4.7 Mg 1.5 mn 0.4 Zr 0.1 Cu 0.2 Alloy fine powder is added in proportion to the mechanical mixer, the volume percentage of silicon carbide is 13.5% of the matrix, the rotation speed is 30r / min, and lasts for 180min. Put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com