A bubble-driven annular micro-unit array assembly system and method

A technology for assembling systems and micro-units, which can be applied to biochemical equipment and methods, biochemical cleaning devices, and devices for human tubular structures, etc. performance and stability, low probability of failure, huge cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

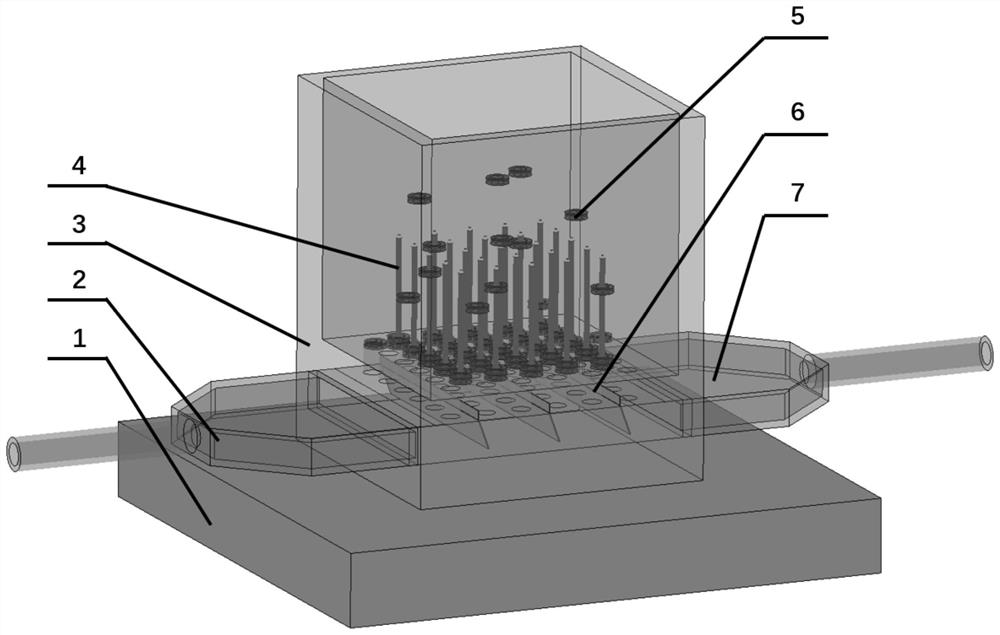

[0034] The microvascular two-dimensional annular unit 5 used in this example has an outer diameter of 250 μm, an inner diameter of 100 μm, and a thickness of 40 μm. It is mixed with the culture solution and poured into the upper chamber of the culture dish 3. 75%, the length, width and height of the petri dish 3 are 15mm, 15mm and 18mm respectively, the wall thickness is 1mm, and the left air inlet pipe 2 and the right air inlet pipe 7 are in a normally closed state.

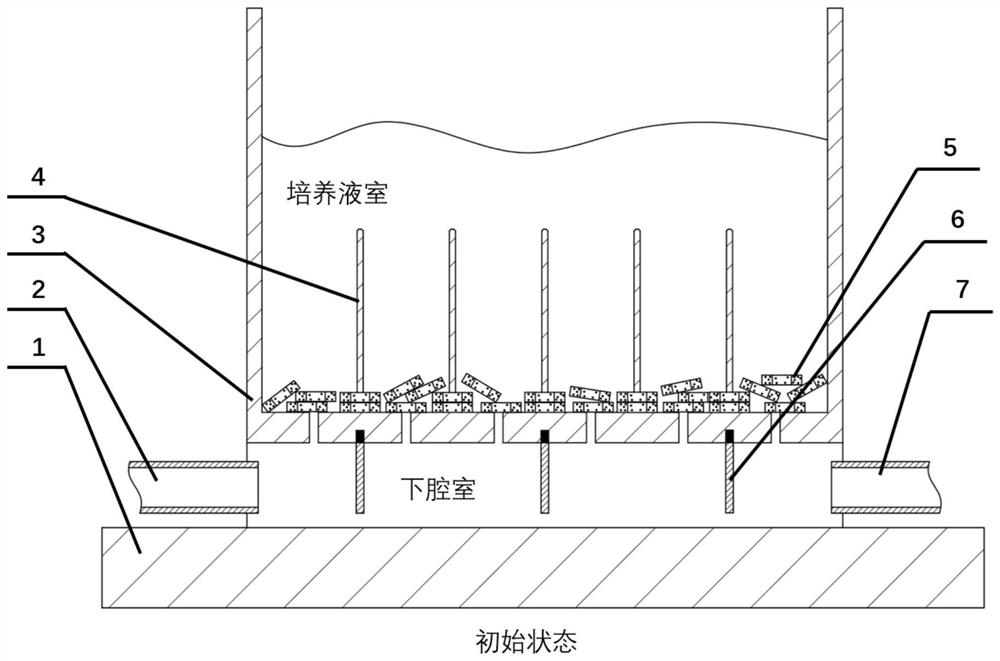

[0035] The specific operation process of a bubble-driven annular micro-unit array assembly method will be fully described below. figure 1 and Figure 2.

[0036] 1. Ensure that the liquid level of the culture solution in the culture dish 3 is 75% of the culture dish 3, and the left air inlet pipe 2 and the right air inlet pipe 7 are in a normally closed state, and the reversing valve 6 is in a straight state;

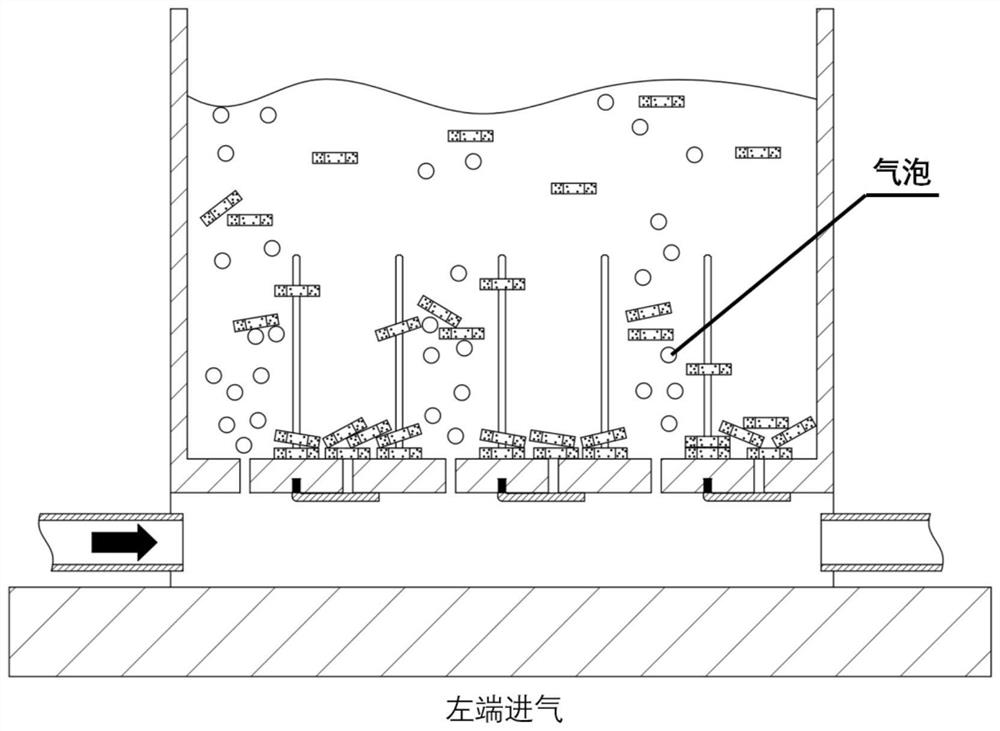

[0037] 2. Open the control valve of the left air inlet pipe 2, and pass compressed gas to the lower ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com