Conveying device for machine tool production

A technology of transportation device and machine tool, which is applied in the field of transportation device for machine tool production, which can solve the problems of increased difficulty in installation and uneven weight of parts, and achieve the effect of simple operation and convenient lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

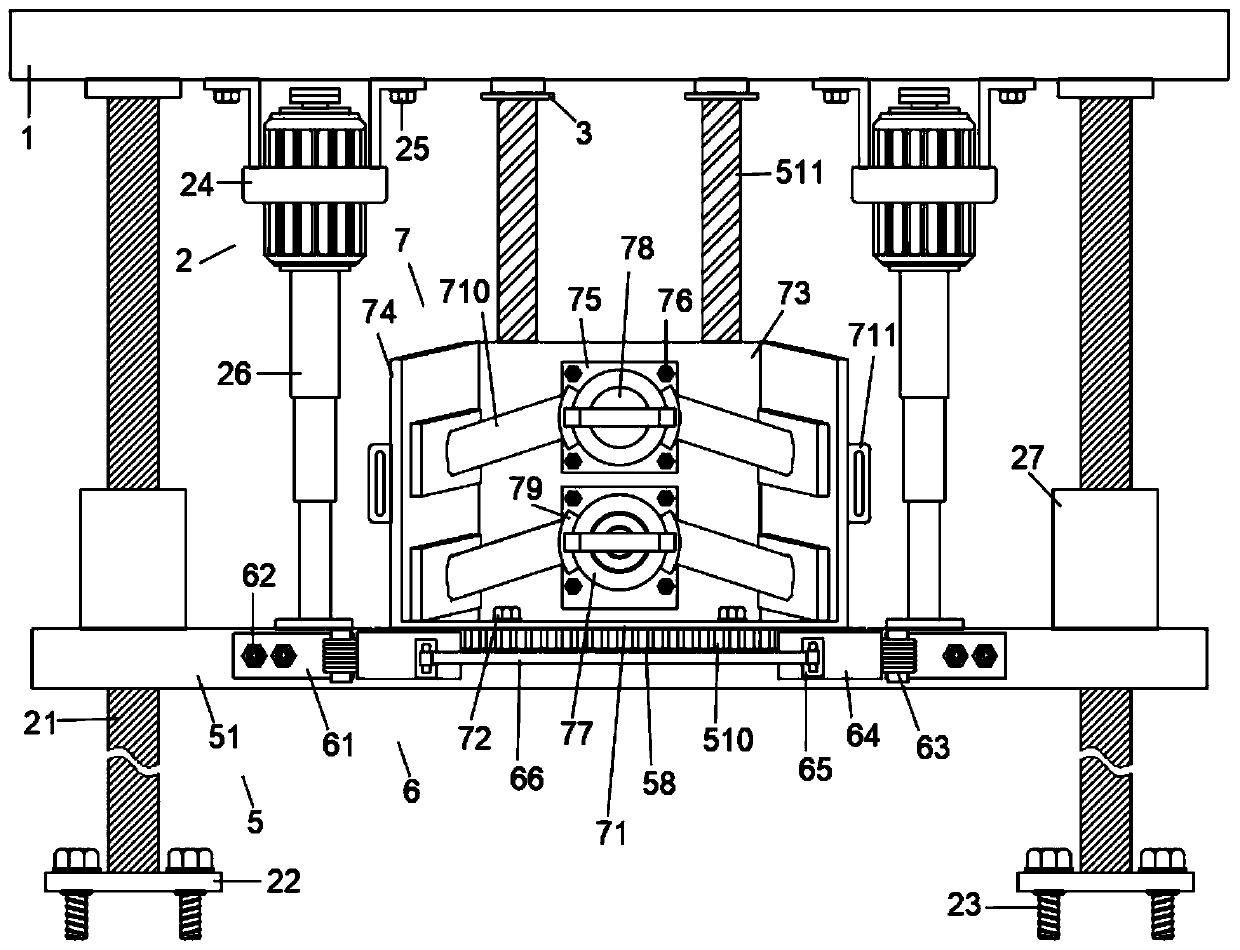

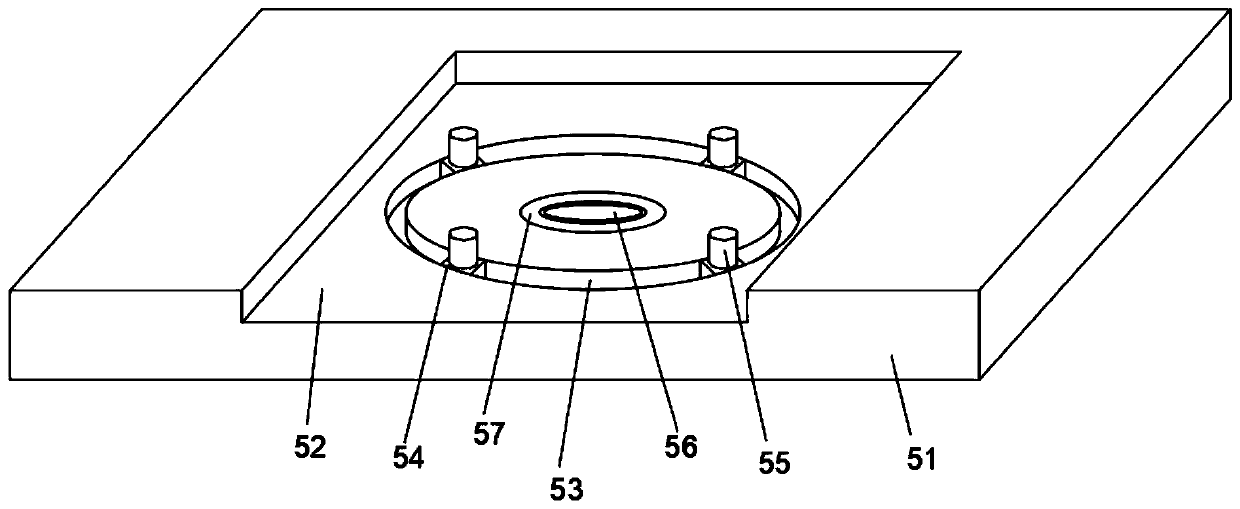

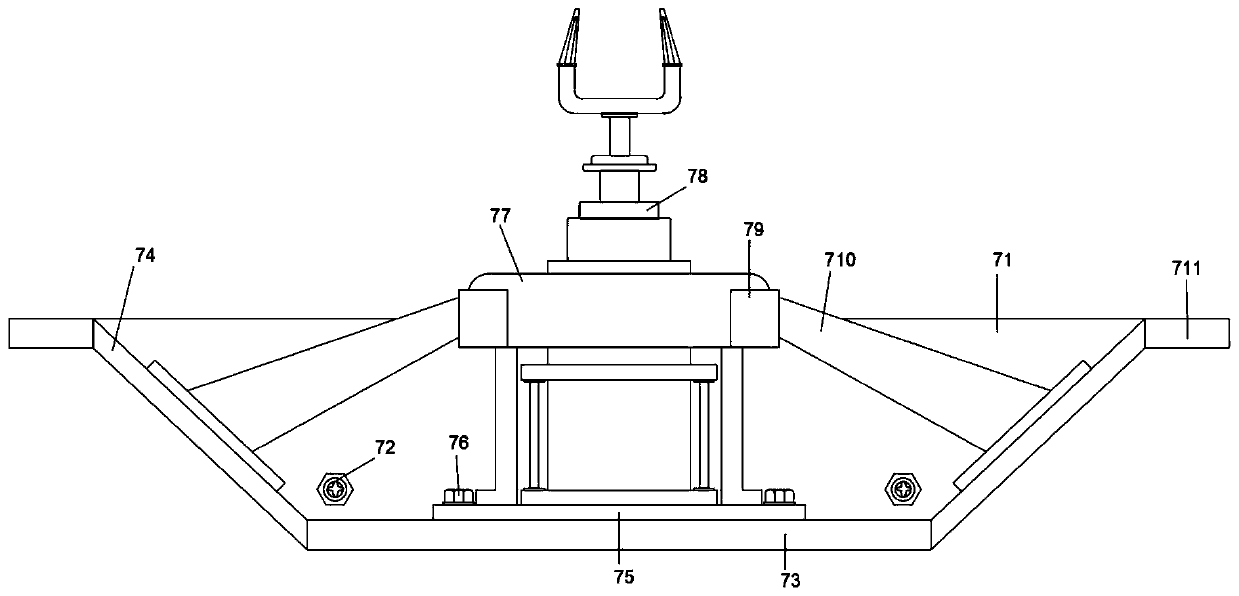

[0032] like Figure 1-9 As shown, this specific embodiment adopts the following technical solutions: a transportation device for machine tool production, including a top plate 1, the bottom four corners of the top plate 1 are respectively connected with the top four corners of the lifting mechanism 2, and the top plate 1 is located at the top of the lifting mechanism 2 An auxiliary chute 3 is excavated between them, and two other auxiliary sliders 4 are slidably connected in the auxiliary chute 3, and the ends of the two auxiliary sliders 4 away from the top plate 1 are connected with the rotating mechanism 5, and the rotating mechanism The top of the 5 is connected with a clamping and limiting mechanism 7, and both ends of the front side wall of the rotating mechanism 5 are connected with an adjusting mechanism 6;

[0033] The lifting mechanism 2 includes four supporting columns 21, a bottom plate 22, a No. 1 bolt 23, two No. 1 frames 24, a No. 2 bolt 25, an electric telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com