Silica gel vibrating diaphragm adhesive tape and preparation method thereof

A silicone diaphragm and tape technology, applied in adhesives, flat products, film/flake adhesives, etc., can solve problems such as the influence of production rate, the limitation of the use effect of silicone diaphragm, and the difficulty in stabilizing the performance parameters of the production diaphragm. , to achieve the effect of improving production efficiency, improving preparation method and good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

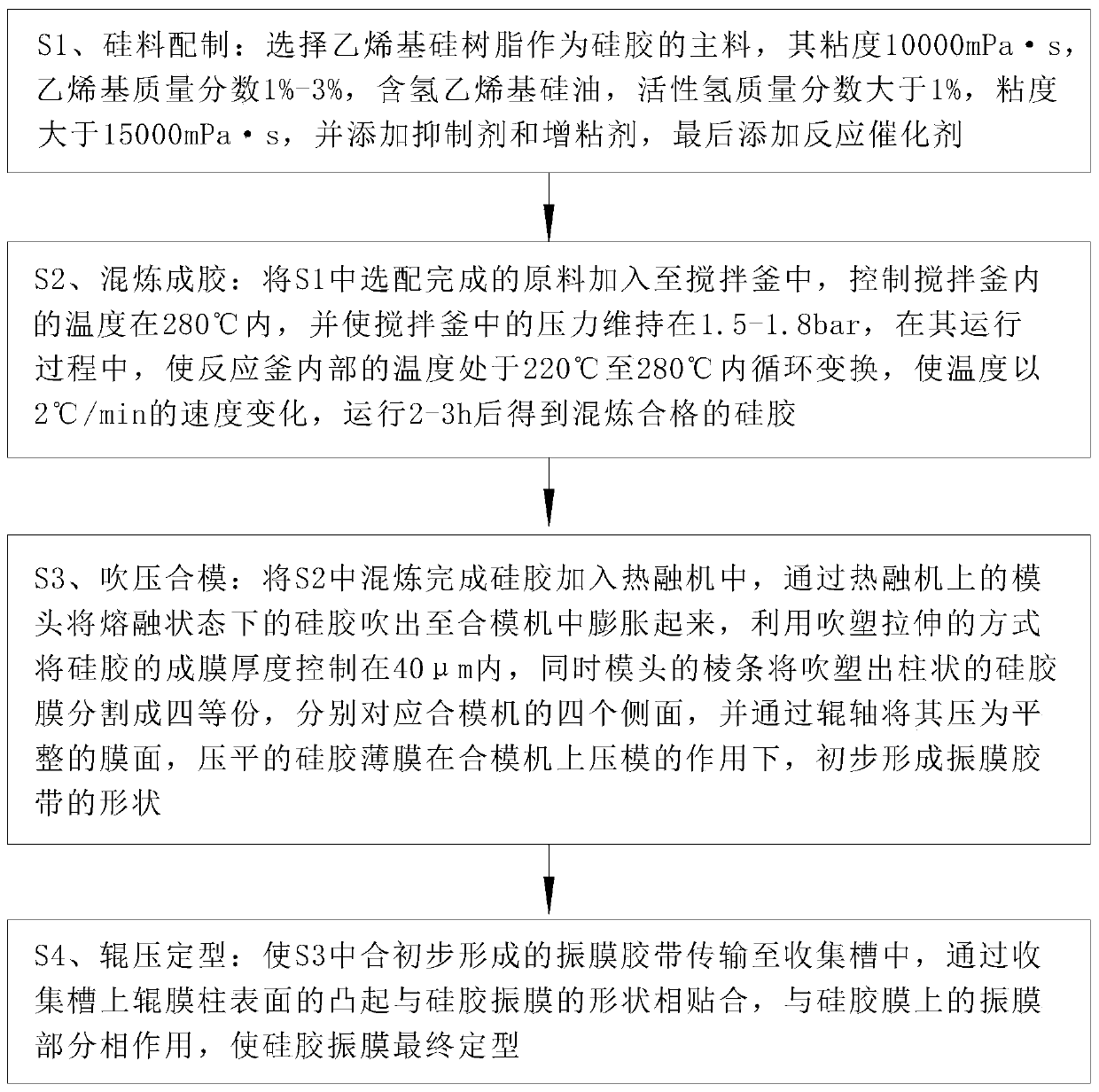

[0032] Such as Figure 1 to Figure 7 Shown, a kind of silica gel diaphragm tape preparation method of the present invention: the method steps are as follows:

[0033] S1. Preparation of silicon material: choose vinyl silicone resin as the main material of silica gel, its viscosity is 10000mPa·s, vinyl mass fraction is 1%-3%, hydrogen-containing vinyl silicone oil, active hydrogen mass fraction is greater than 1%, and viscosity is greater than 15000mPa s, and add inhibitors and tackifiers, and finally add reaction catalysts;

[0034] S2. Mixing into gel: Add the selected raw materials in S1 into the stirred tank, control the temperature in the stirred tank within 280°C, and maintain the pressure in the stirred tank at 1.5-1.8bar, during its operation In the process, the temperature inside the reactor is cyclically changed from 220°C to 280°C, and the temperature is changed at a speed of 2°C / min. After running for 2-3 hours, qualified silica gel for mixing is obtained; the temp...

Embodiment approach

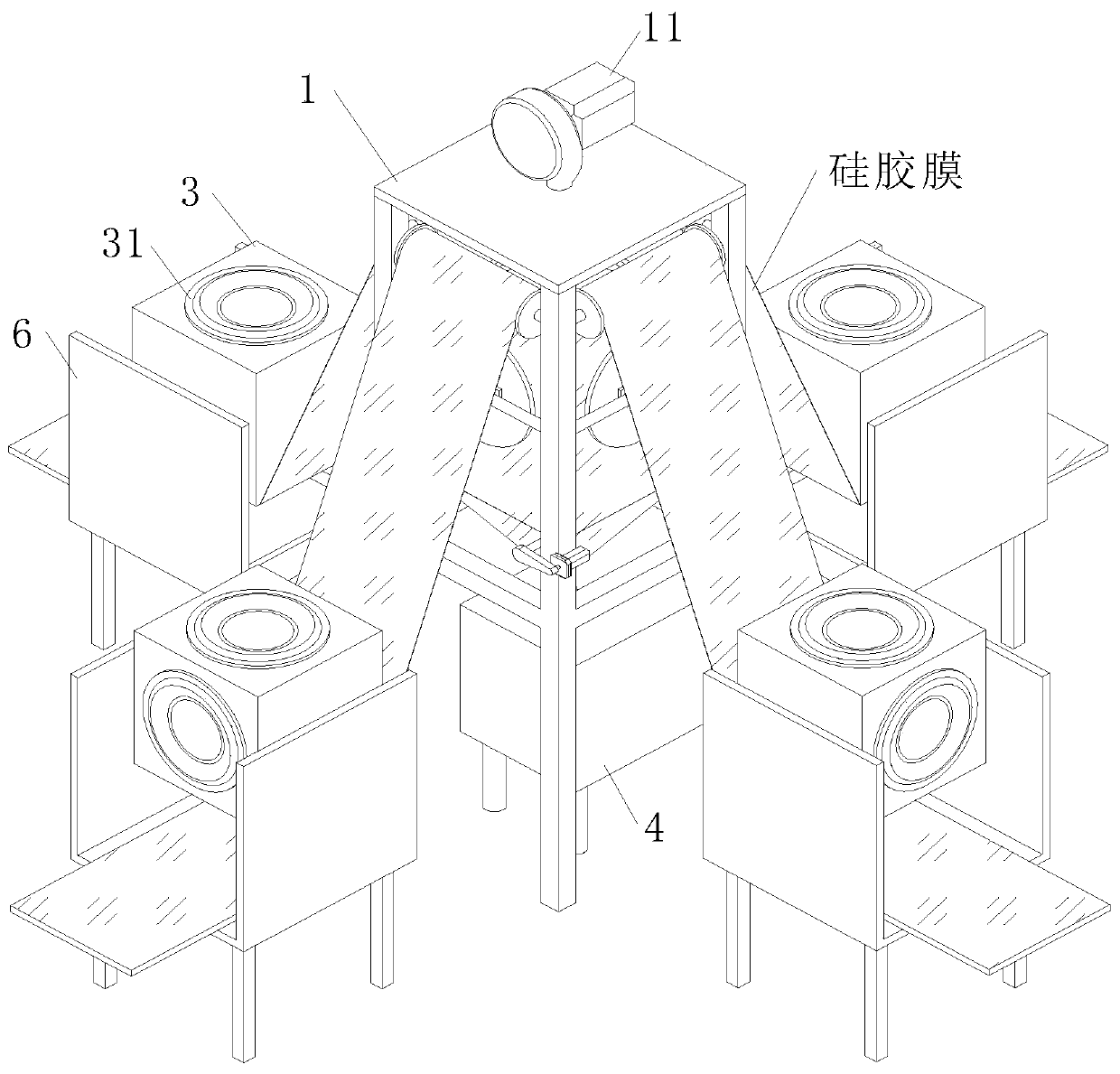

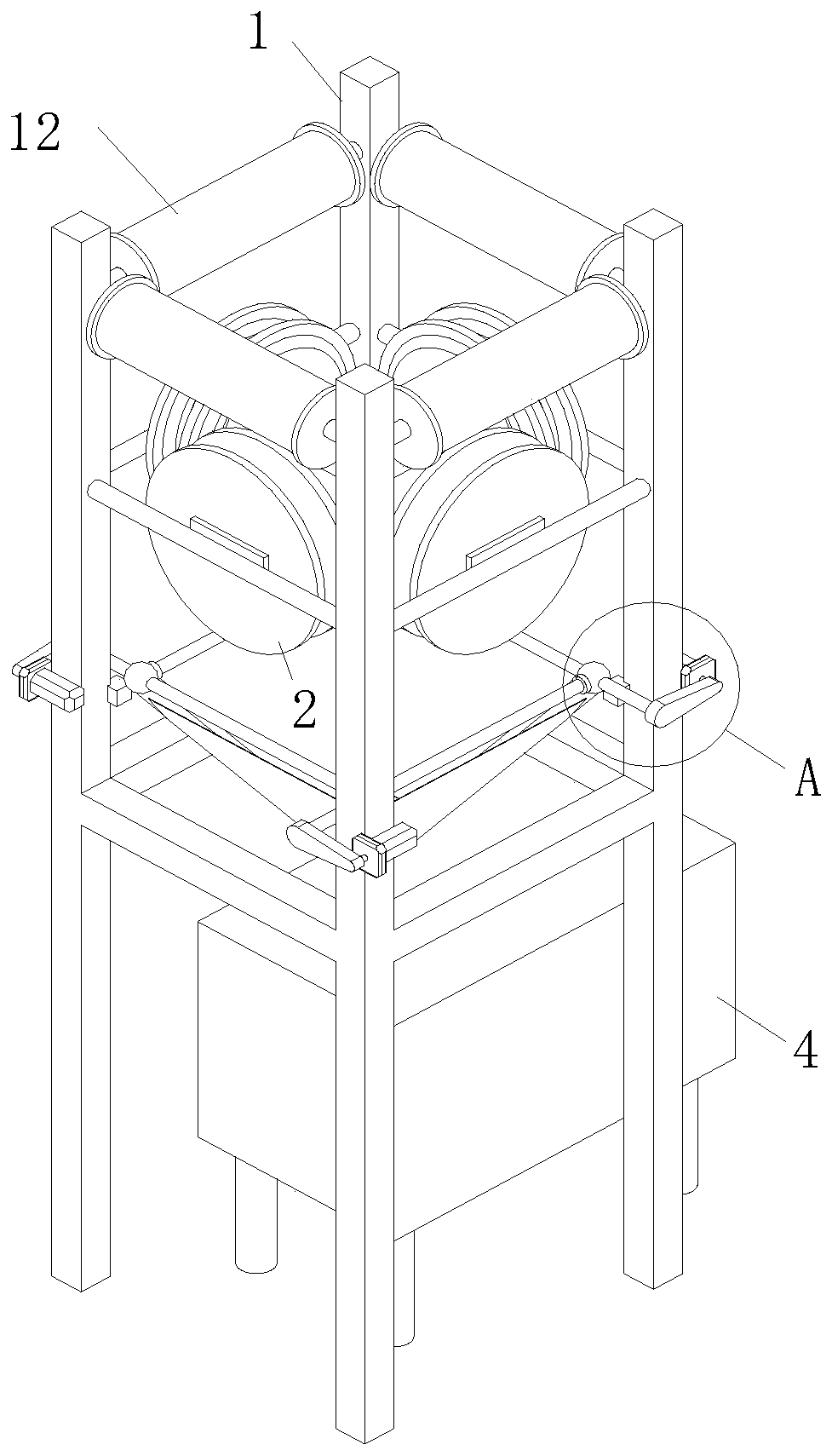

[0040] As an embodiment of the present invention, the rib 42 is provided with a spoiler 44 at a position close to the air outlet 51 of the prism 5, the bottom of the spoiler 44 is provided with a shaft column 441, and the shaft column 441 is vertically rotated and installed on the On the rib 42; the spoiler 44 is affected by blow molding and swings left and right; the blown silicone film is divided into four parts under the action of the rib 42, and the airflow blown from the top of the rib 5 is along four directions Scattered, the airflow blown out from the tuyere 51 on the adjacent two sides of the edge platform 5 interferes with each other, which affects the uniform thickness of the blown silicone film and reduces the quality of the diaphragm pressed by the diaphragm; The spoiler 44 on the edge separates the airflow of the adjacent air outlet 51 on the edge platform 5, and the airflow blown out by the adjacent air outlet 51 on the edge platform 5 is adjusted by the spoiler 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com