Five-channel remote spinning color mixing 3D printer

A 3D printer, five-channel technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problems of single molding color of printed products, inability to obtain product color accurately, poor structural stability, etc. Intensity, stable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

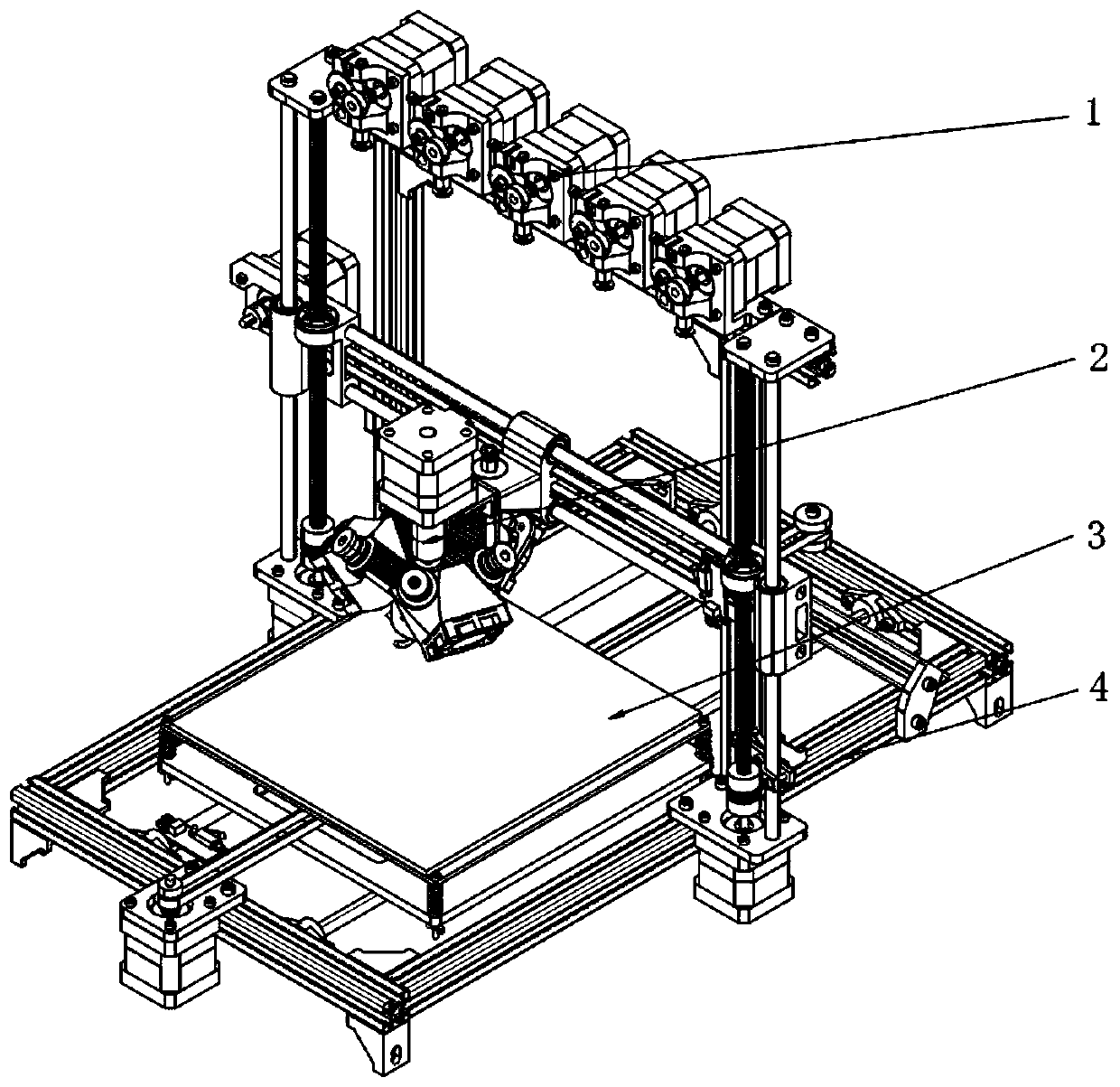

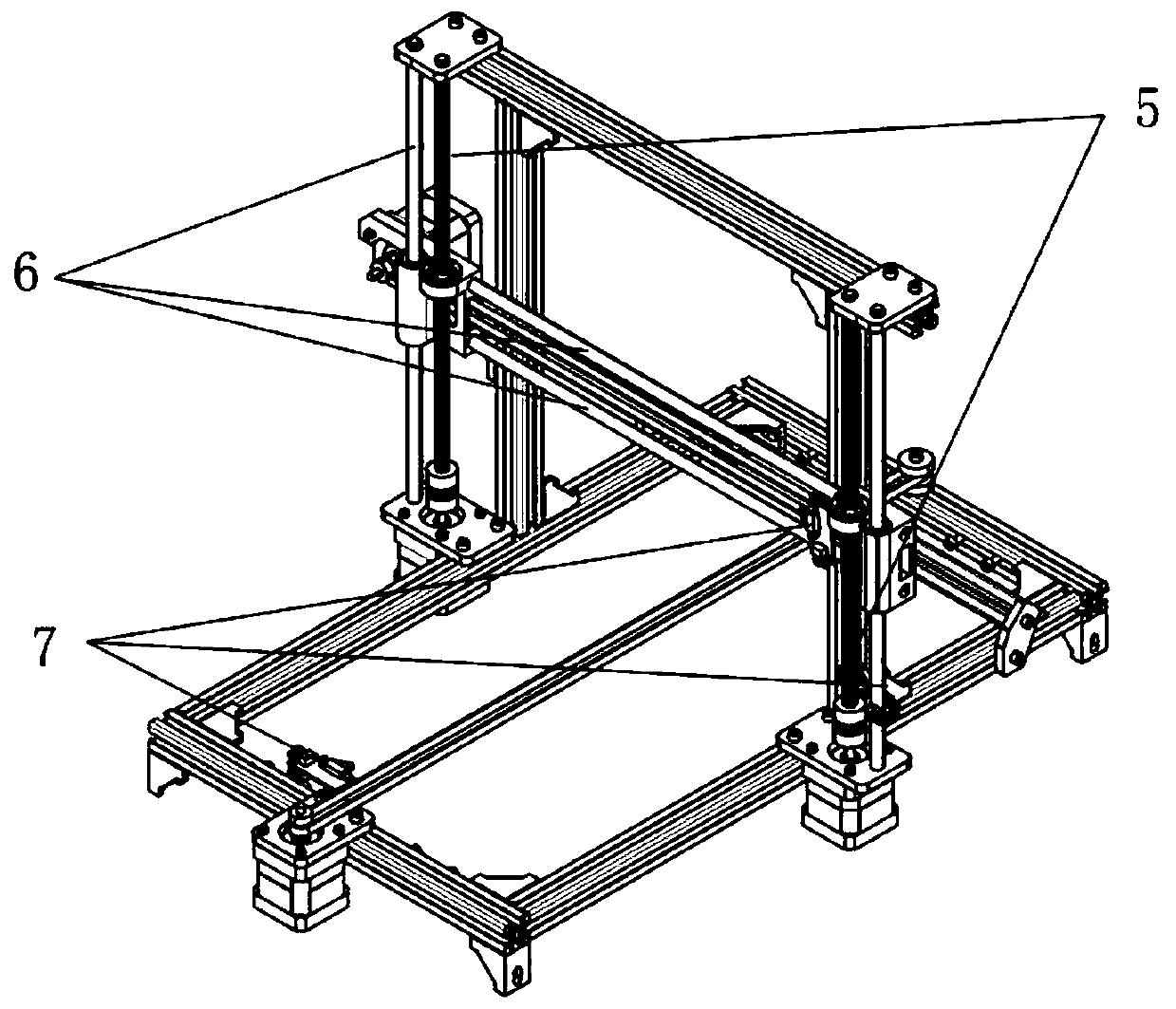

[0037] Specific implementation mode one: see Figure 1-Figure 10 This embodiment will be described. The five-channel remote spinning and color mixing 3D printer described in this embodiment includes a feeding device 1, a nozzle assembly 2, a loading platform 3, and a frame 4, and the frame 4 includes a base, a bracket, and a double screw lifting mechanism 5. The base and the support are perpendicular to each other, the double screw lifting mechanism 5 is installed in the support, the support slides back and forth along the slide rails on both sides of the base, and the top of the support is equipped with a feeding device 1, so A nozzle assembly 2 is installed on the beam of the double screw lifting mechanism 5, and the nozzle assembly 2 moves along the Z and Y directions in the bracket, and a loading platform 3 is installed in the base, and the loading platform 3 moves along the inside of the base The sliding rails on both sides move in the X direction, and the feeding device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com