Automatic laminating equipment for marble tile manufacturing

A marble and film-covering technology, which is applied in chemical instruments and methods, building components, metal processing, etc., can solve problems such as unsatisfactory, easy to stick impurities, and affect the quality of ceramic tiles, so as to improve the quality and efficiency of bonding, improve Quality and efficiency, the effect of improving economical practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

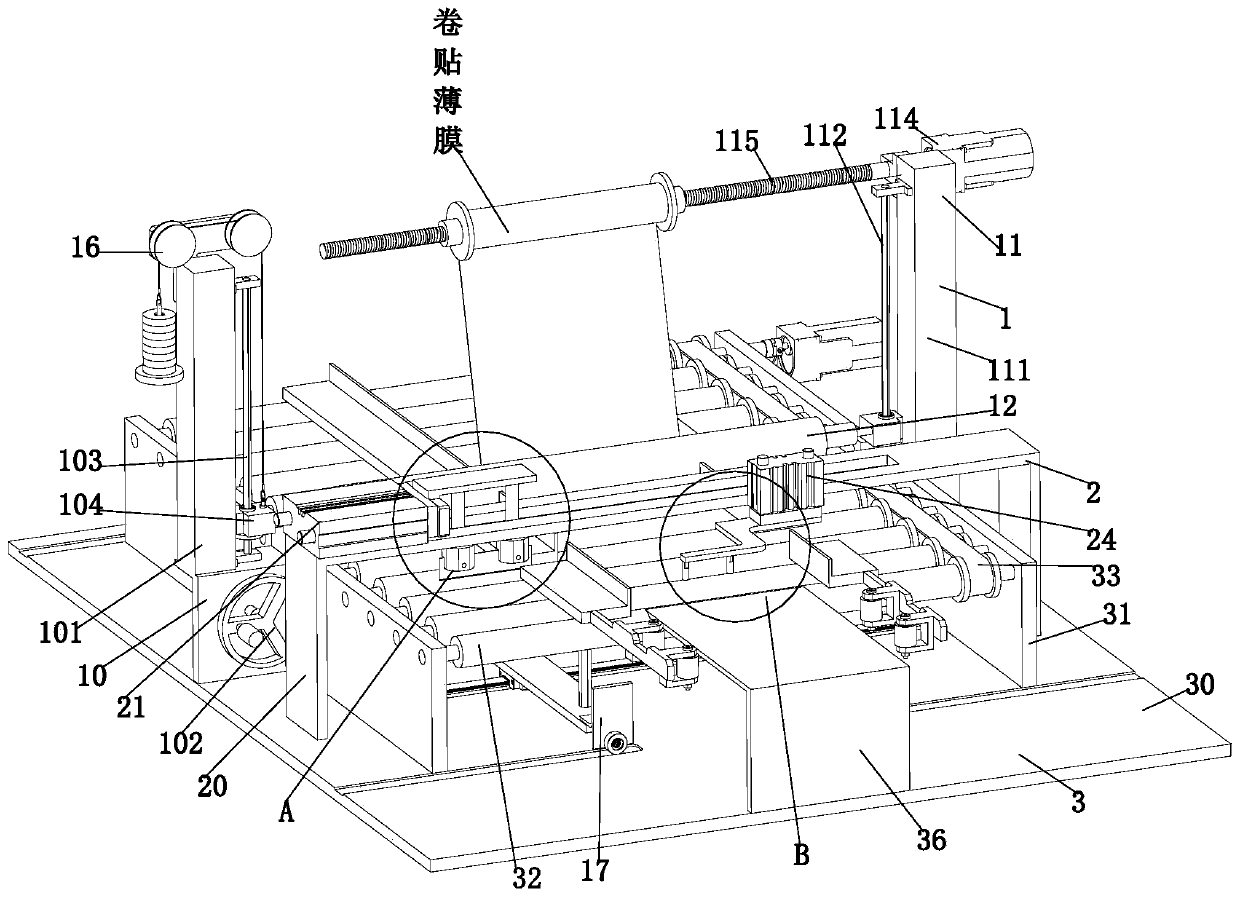

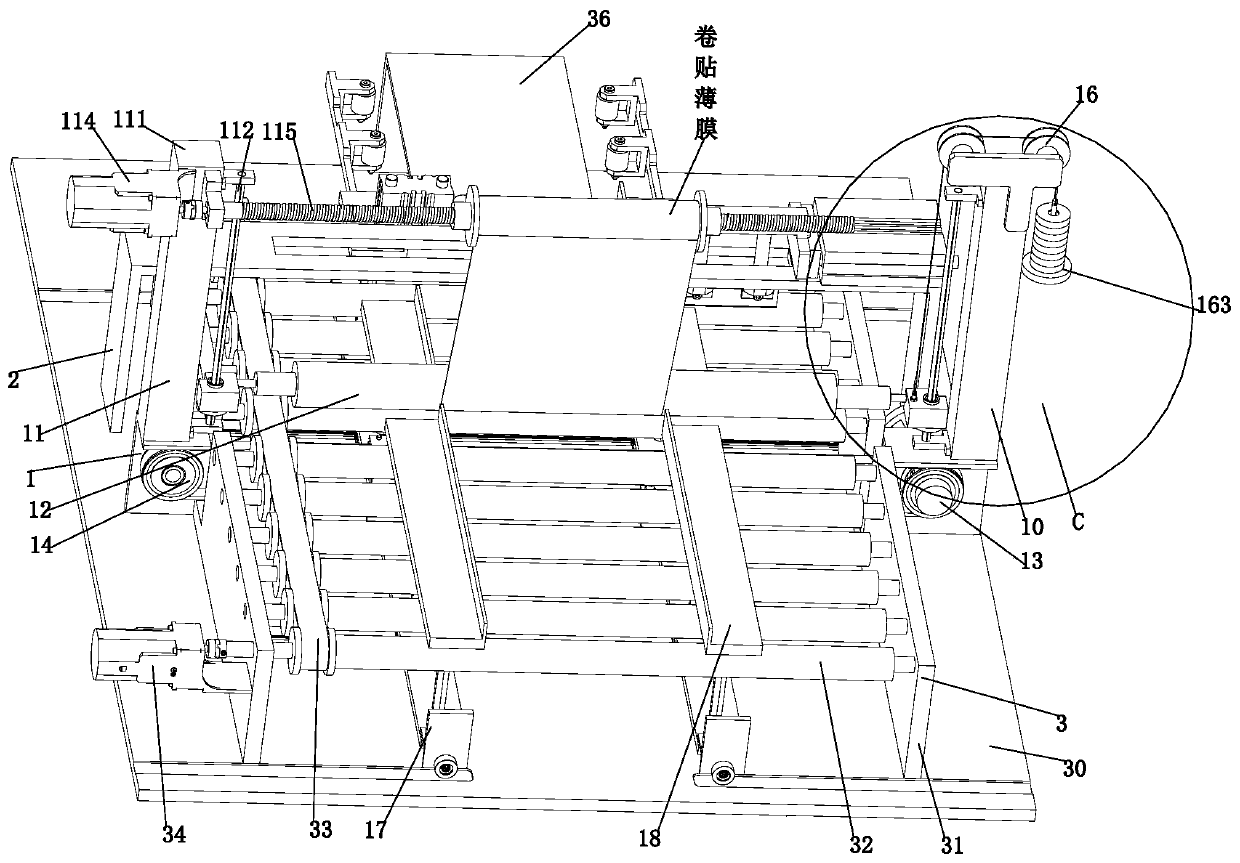

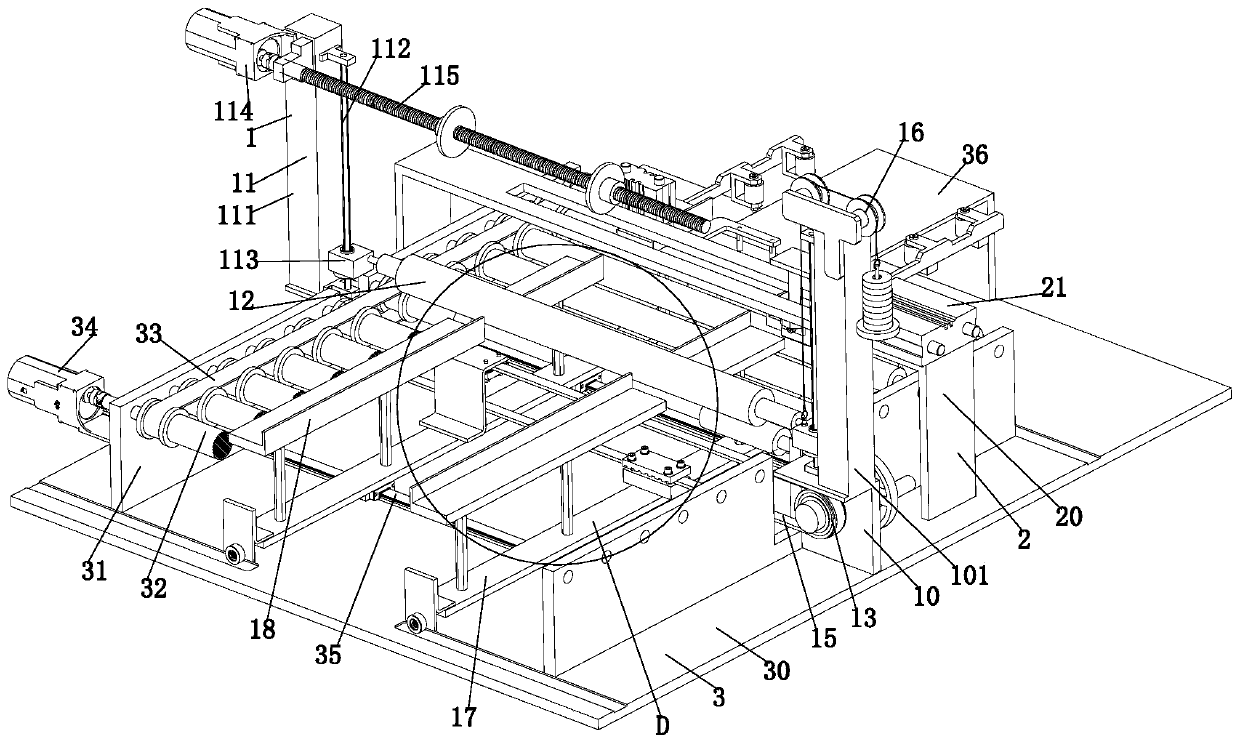

[0028] Such as Figure 1 to Figure 7 As shown, an automatic coating equipment for manufacturing marble tiles includes an actuator 1, a cutting mechanism 2 and a transmission mechanism 3. The actuator 1 is installed on the transmission mechanism 3 by sliding fit, and is located A cutting mechanism 2 is provided at the position directly in front of it, and the cutting mechanism 2 is installed on the transmission mechanism 3, wherein:

[0029] The actuator 1 includes a left column unit 10, a right column unit 11, a coating cylinder 12, a left pulley 13, a right pulley 14, a toothed transmission belt 15, a lifting unit 16, a carriage 17, a guide bracket 18 and Synchronous toothed plate 19; the left column unit 10 and the right column unit 11 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com