A wiring harness fixing card for a vehicle

A wire harness fixing and vehicle-used technology, which is applied in the direction of vehicle components, circuits or fluid pipelines, electrical components, etc., to achieve good fixation and meet the effect of coordination and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

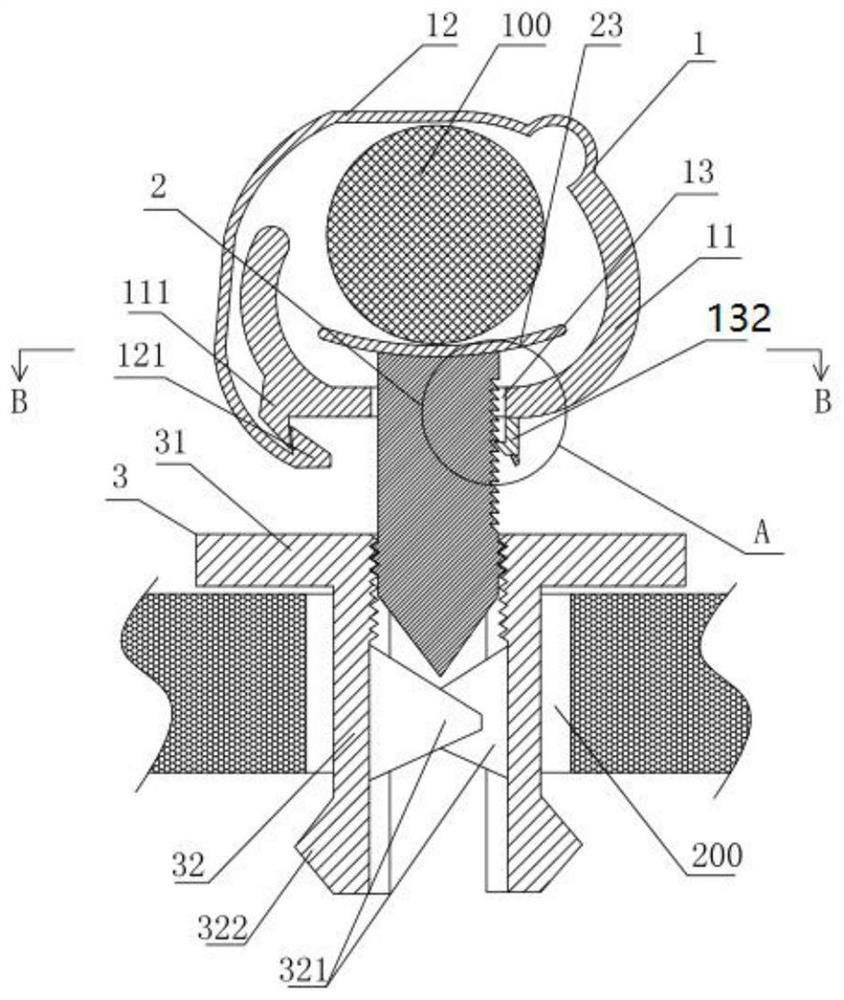

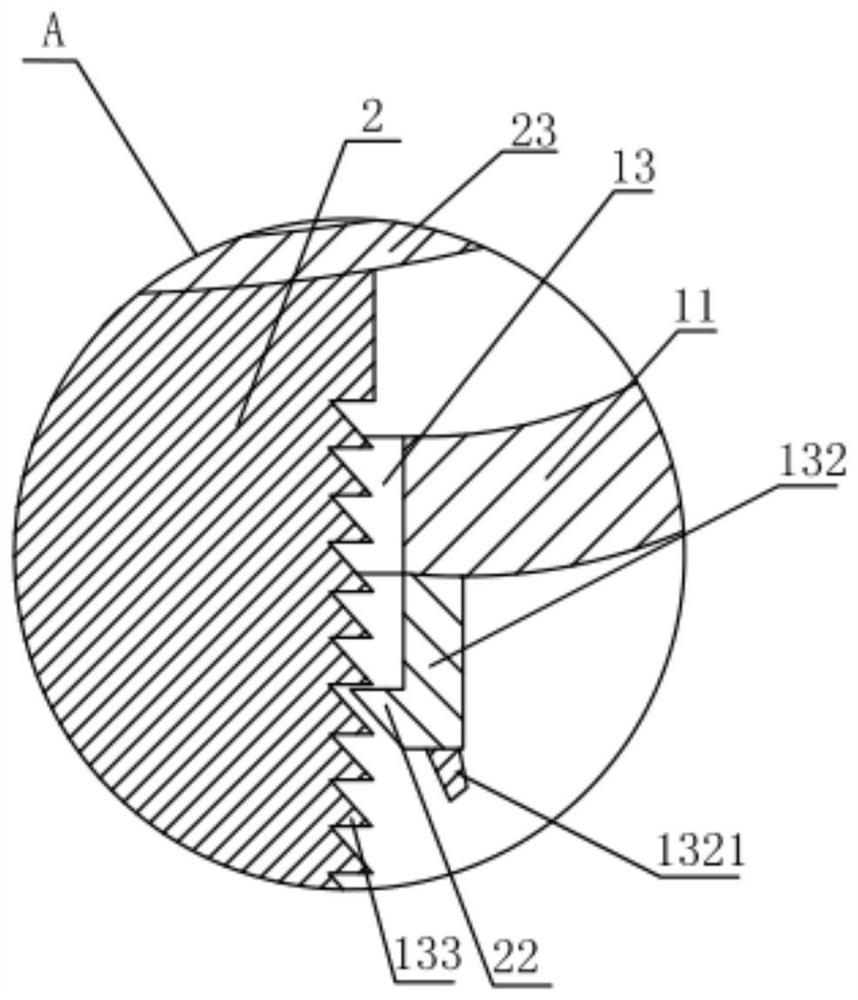

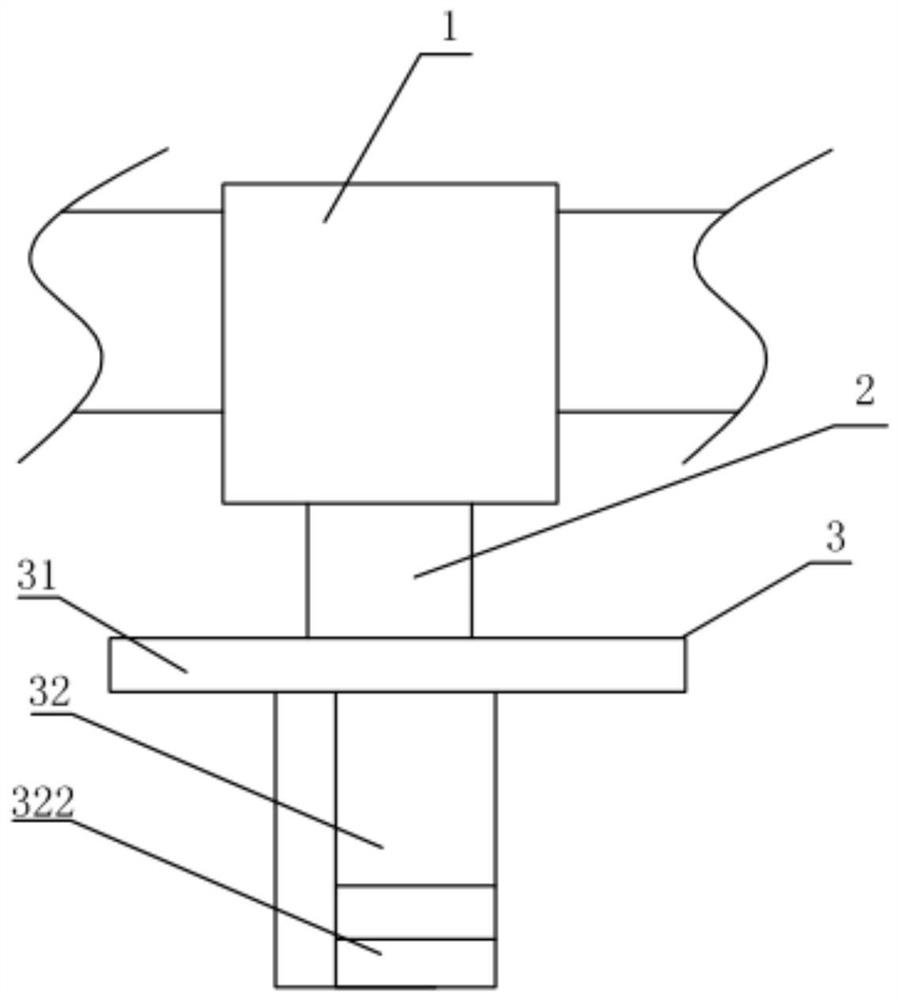

[0023] like Figure 1 to Figure 5 As shown, a vehicle wire harness fixing card according to the present invention includes a wire binding ring 1, a central column 2 and a positioning seat 3. The wire binding ring 1 includes a fixed arc plate 11 and a movable arc plate 12. The fixed The arc plate 11 opens upwards, its left end overhangs upwards, its right end extends upwards and is fixedly connected to one end of the movable arc plate 12, and the other end of the movable arc plate 12 extends downwards and covers the outside of the left end of the fixed arc plate 11, The bottom left side of the movable arc plate 12 is provided with an upward protruding bayonet A121, and the bottom left end of the fixed arc plate 11 is provided with a downward protruding bayonet B111. The bayonet opening B111 is buckled together to realize the fixing of the wire harness 100, and the space enclosed by the fixed arc plate 11 and the movable arc plate 12 is used for placing the wire harness 100; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com