Clamp with self-locking function for products in irregular shapes

A technology for irregular products, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of not being able to clamp irregular products, and achieve the effect of improving versatility, convenience, good economy, and outstanding economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

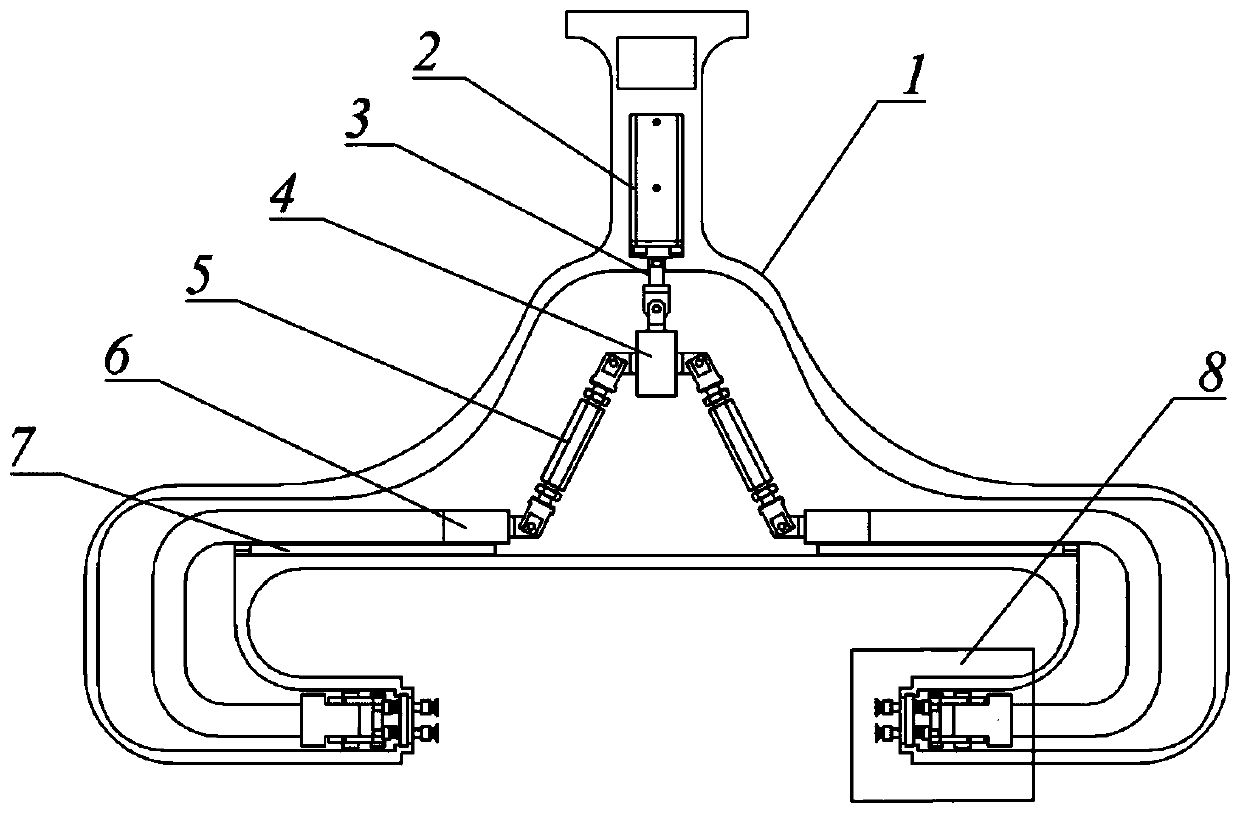

[0027] The present invention will be further explained below in conjunction with the drawings:

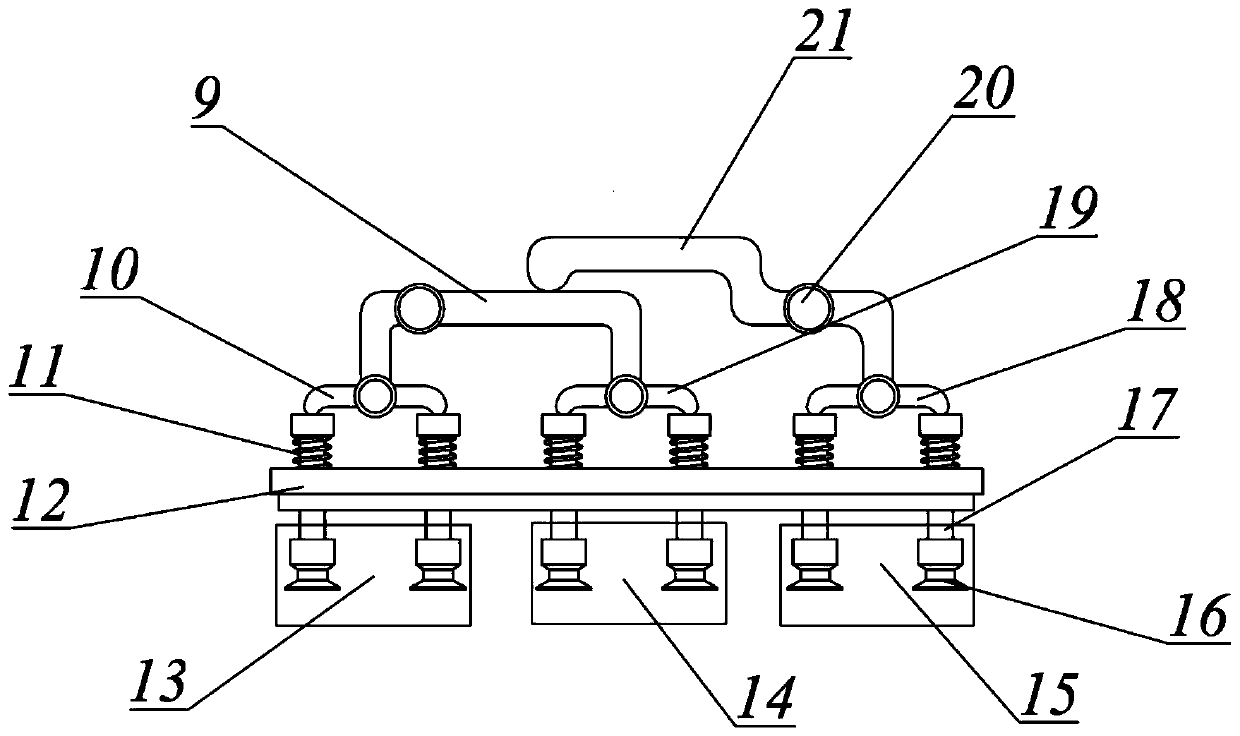

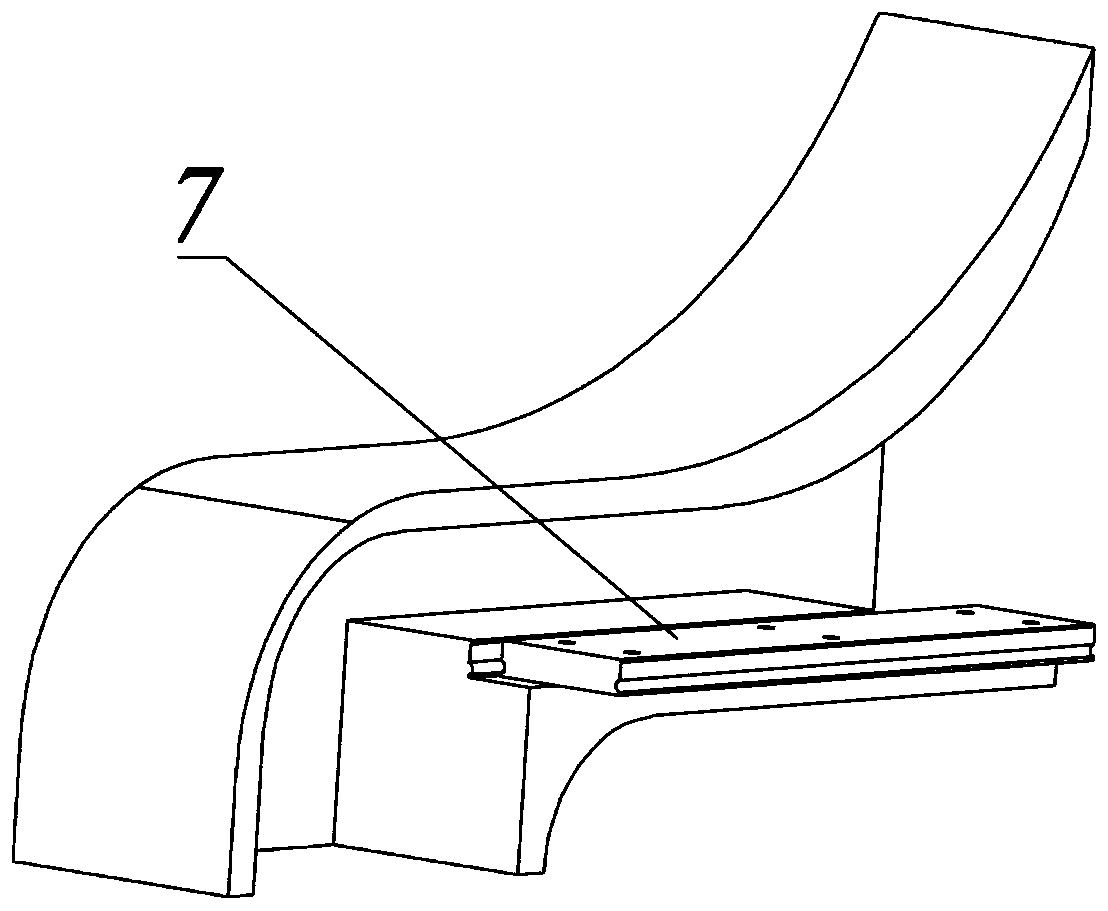

[0028] The specific working process as shown in the figure is as follows: figure 1 This is the internal overall structure of the present invention (the shell 1 is drawn in half). The cylinder 2 is connected to the push rod 3 by threads, the push rod 3 is fixed on the slider 4 through the hinge seat, and the slider 4 is connected to two connecting rods 5 on the left and right sides through the hinge. The connecting rod 5 has threads to achieve length expansion . The left and right connecting rods 5 are respectively connected with a gripper 6 through a hinge seat. At the same time, a T-shaped guide rail 7 is connected to the gripping hands 6 on the left and right sides, so that the gripping grip 6 and the guide rail 7 can slide horizontally on the housing 1. A clamping jaw device 8 is connected to the end of the clamping hand 6, and the object positioning, clamping, and transportation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com