Guiding blade mold and design method for contraction thereof

A guide vane and mold shrinkage technology, which is applied in the field of precision casting, can solve the problems of prolonged delivery period, inability to open the mold, and out-of-tolerance blade throat area, and achieve the goal of solving mold opening interference, promoting engineering application, and improving design technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A slender five-joint equiaxed crystal turbine guide vane of an engine blade:

[0054] Step 1, set parameters

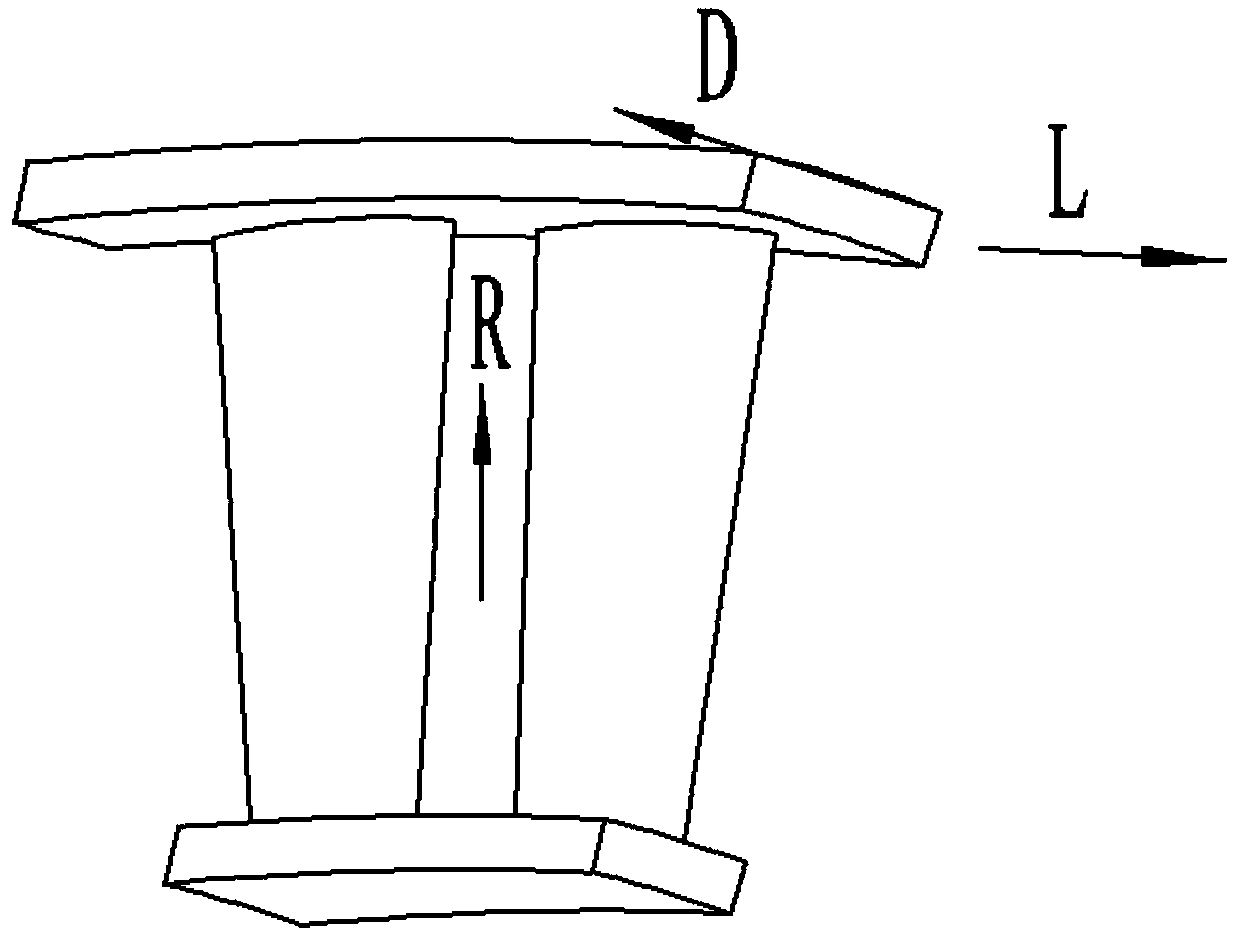

[0055] The length of the blade body is A=225mm; the length direction of the blade is the R direction, which coincides with the coordinate axis Z axis, and the shrinkage rate is ψ1=2.4%;

[0056] The chord length direction of the upper and lower edge plates is the L direction, which coincides with the X axis of the coordinate axis, and the shrinkage rate is ψ2=1.8%;

[0057] The width direction of the upper and lower edge plates is the D direction, which coincides with the coordinate axis Y axis, and the shrinkage rate is ψ3=1.8%.

[0058] Step 2, mold shrinkage setting method

[0059] Taking the origin of the blade engine as the center of the circle, the blade is enlarged as a whole according to the shrinkage rate of 1.8%. The shrinkage rate given in the direction of the blade body is 0.6% smaller than the actual shrinkage rate, and the length of the blade bo...

Embodiment 2

[0062] A single-connected equiaxed crystal turbine guide vane with short blade body and large edge plate in an engine:

[0063] Step 1, set parameters

[0064] The blade body length is A=110mm;

[0065] The length direction of the blade is the R direction, which coincides with the coordinate axis Z axis, and the shrinkage rate is ψ1=1.8%;

[0066] The chord length direction of the upper and lower edge plates is the L direction, which coincides with the X axis of the coordinate axis, and the shrinkage rate is ψ2=2.2%;

[0067] The width direction of the upper and lower edge plates is the D direction, which coincides with the coordinate axis Y axis, and the shrinkage rate is ψ3=2.2%.

[0068] Step 2, mold shrinkage setting method

[0069] Taking the origin of the blade engine as the center of the circle, the blade is enlarged as a whole according to the shrinkage rate of 2.2%. The shrinkage rate given in the direction of the blade body is 0.4% larger than the actual shrinkage...

Embodiment 3

[0071] A single directionally solidified turbine guide vane with the same size as the airfoil and edge plate of an engine:

[0072] Step 1, given parameters

[0073] The blade body length is A=180mm;

[0074] The length direction of the blade is the R direction, which coincides with the coordinate axis Z axis, and the shrinkage rate is ψ1=1.6%;

[0075] The chord length direction of the upper and lower edge plates is the L direction, which coincides with the X axis of the coordinate axis, and the shrinkage rate is ψ2=2.1%;

[0076] The width direction of the upper and lower edge plates is the D direction, which coincides with the coordinate axis Y axis, and the shrinkage rate is ψ3=2.1%.

[0077] Step 2, mold shrinkage setting method

[0078] Taking the origin of the blade engine as the center of the circle, the blade is enlarged as a whole according to the shrinkage rate of 2.1%. The shrinkage rate given in the direction of the blade body is 0.5% larger than the actual shr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com