A large-scale three-way high-efficiency automatic die forging device and die forging method thereof

A tee and die forging technology, applied to forging/pressing/hammer devices, engine components, forging/pressing/hammering machinery, etc., can solve problems such as low efficiency, inapplicability to mass production, and large losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

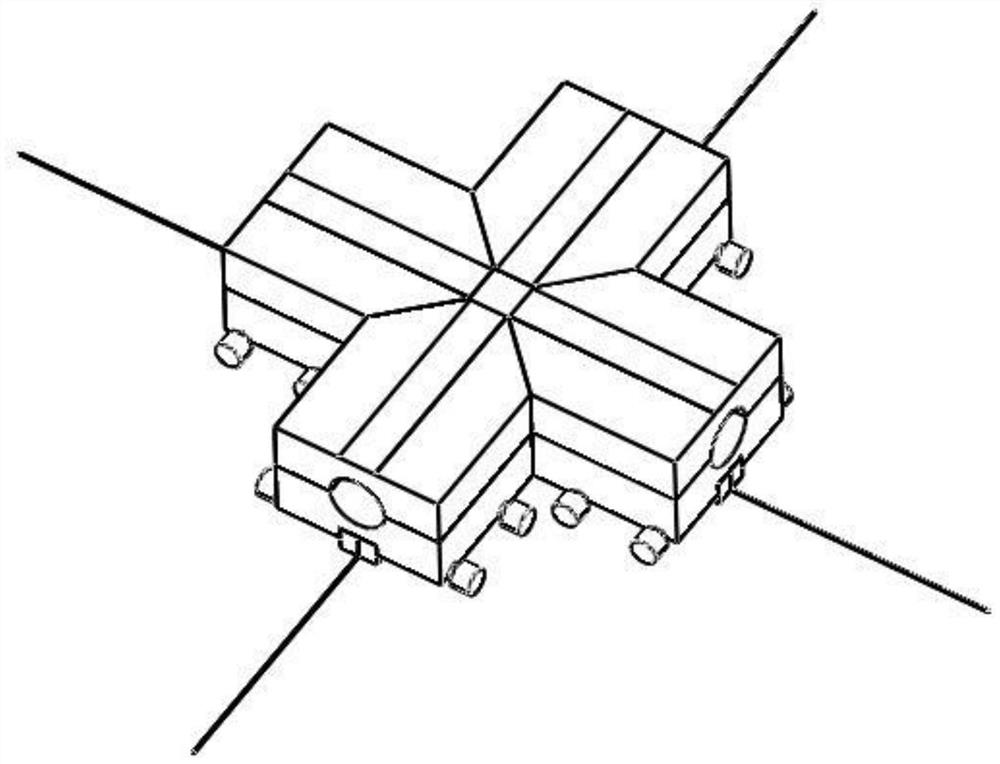

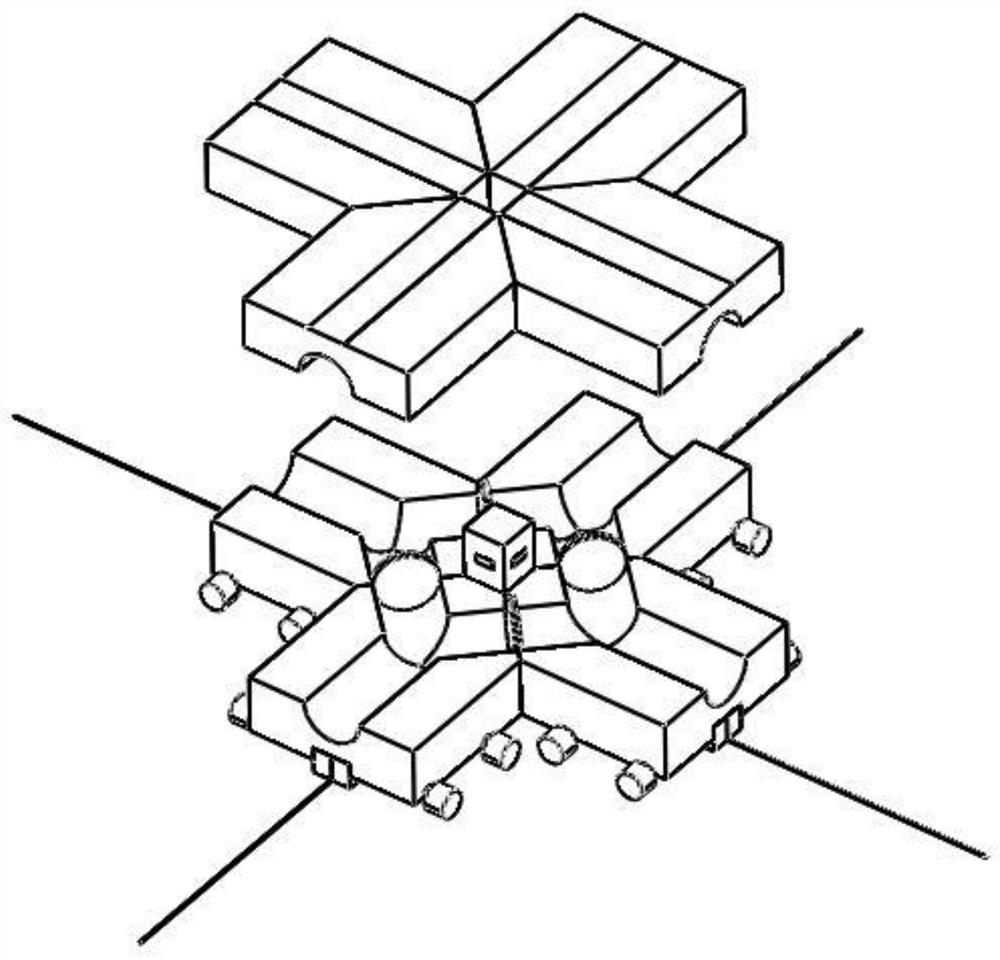

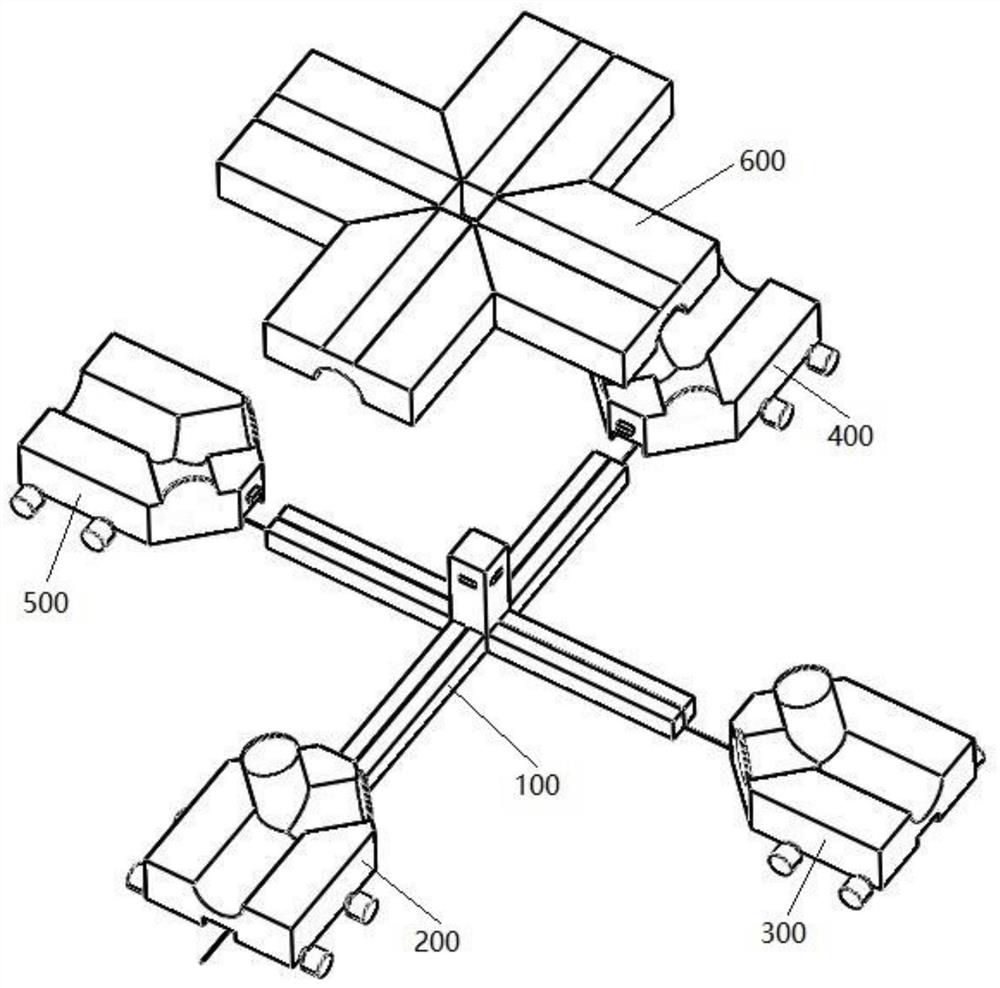

[0038] Embodiment 1: as Figure 1 to Figure 10 As shown, a large-scale three-way high-efficiency automatic die forging device proposed by the present invention includes a base 100, four lower mold trolleys 200 that can move relatively, and an upper mold 600 connected to the four lower mold trolleys 200.

[0039] Wherein the base 100 includes four support rails 101 respectively corresponding to the lower mold trolley 200 and arranged in a cross shape, and a column 110 located in the middle of the base 100. The column 110 is arranged in a square column shape and is fixed at the center of the four support rails 101 , the end surfaces of the four lower mold trolleys 200 can abut against the side walls of the columns 110 . In addition, the upper surface of the support rail 101 is respectively provided with thin strip grooves and embedded wires 105. The four wires 105 are all connected with extension wires 1051. The extension wires 1051 are arranged on the ground. device.

[0040]...

Embodiment 2

[0044] Embodiment 2, a die forging method of the large-scale three-way high-efficiency automatic die forging device of embodiment 1, comprises the following steps:

[0045] Step 1. The four lower mold trolleys 200 are respectively moved to the vicinity of the heating furnace along the corresponding routes; and the cylindrical metal blank material to be extruded is heated to 1200 degrees Celsius in the heating furnace, taken out by the clamp, and placed in the It corresponds to the main cavity 202 of the lower mold trolley 200 .

[0046] Step 2, transportation, the extension wire 1051 and the wire 105 are energized, a magnetic field is generated around the wire 105 and the extension wire 1051, the electromagnetic sensor 208 detects the magnetic signal, and transmits the signal to the host computer, and the host computer controls the power unit 213 to start working, and drives The wheel 209 rotates, the lower mold trolley 200 obtains power, and the differential speed of the whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com