A steel ring presser foot chamfering all-in-one machine

An all-in-one machine and steel ring technology, applied in the field of steel ring manufacturing, can solve problems such as low efficiency, injury, cutting hands, etc., achieve the effects of reducing labor intensity, realizing processing automation, and improving safety and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

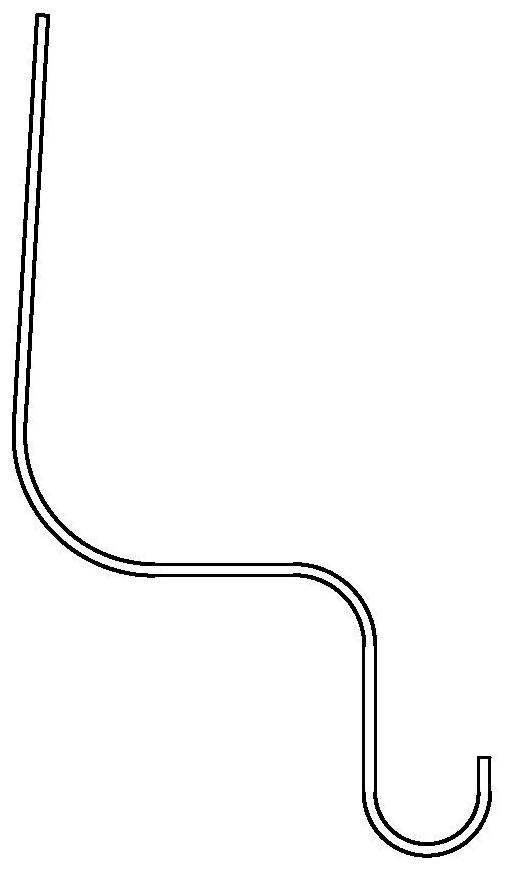

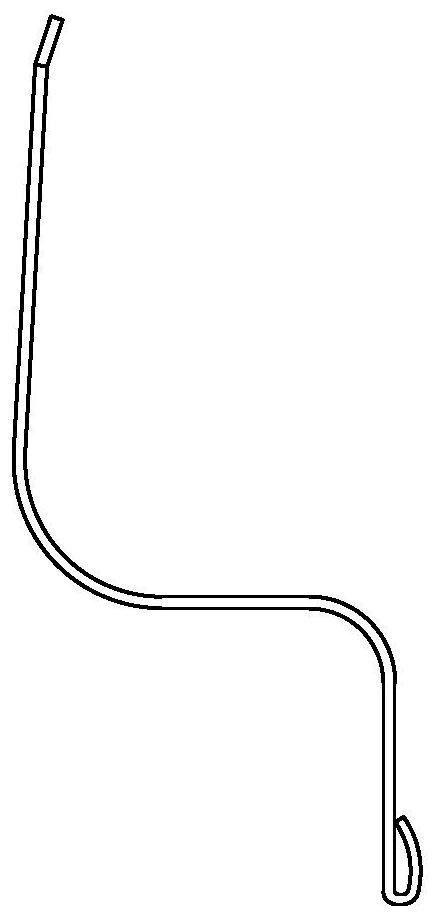

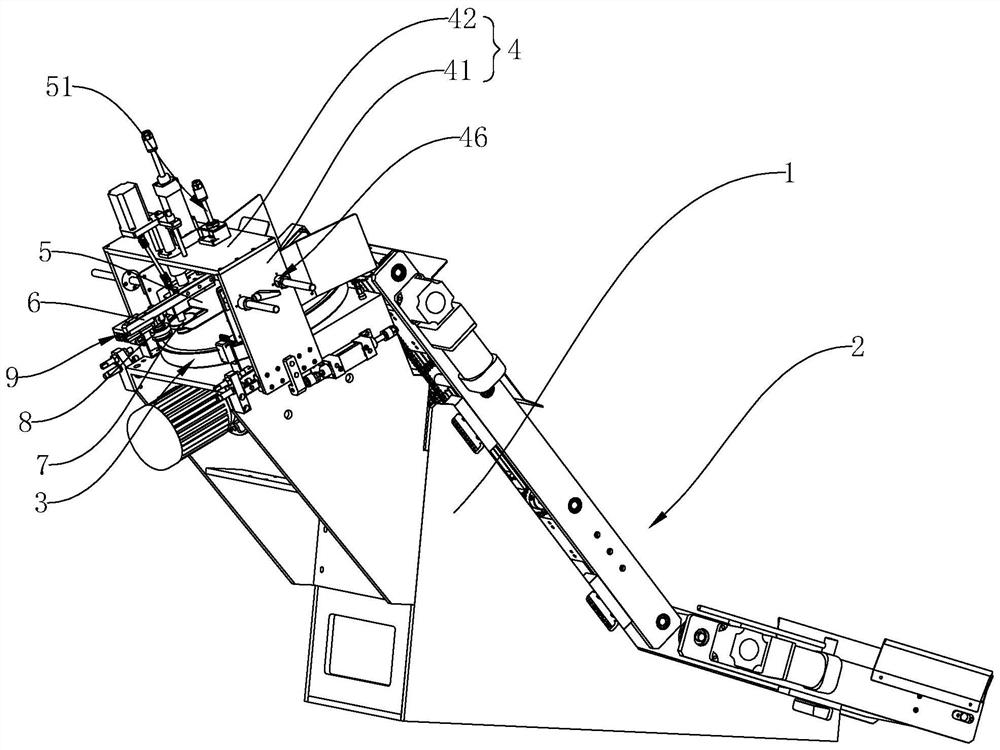

[0038] Embodiment 1: As shown in the figure, a steel ring presser foot chamfering machine includes

[0039] Rack 1;

[0040] A transmission mechanism 2, the transmission mechanism 2 is arranged on the frame 1, and is used to transmit the steel ring to be processed;

[0041] A turntable mechanism 3, the turntable mechanism 3 is arranged on the frame 1, and is used to receive the steel ring to be processed delivered by the transmission mechanism and make the steel ring to be processed rotate;

[0042] A mobile frame 4, the mobile frame 4 can move forward and backward and is arranged on the frame 1, and is located above the turntable mechanism 3;

[0043] A pressing plate 5, the pressing plate 5 is arranged on the mobile frame 4 through the lifting mechanism 51, and is used for contacting with the steel ring to be processed;

[0044] Press down bar 6, and press down bar 6 can move up and down by pressing down mechanism 61 and be arranged on moving frame 4;

[0045] A driving w...

Embodiment 2

[0049] Embodiment two: as shown in the figure, other structures are identical with embodiment one, and its difference is that transmission mechanism 2 comprises belt conveying unit 21 and chain conveying unit 22, and belt conveying unit 21 is arranged on the bottom of frame 1 back, And it is used to transport the steel rings to be processed to the entrance of the chain conveyor unit 22, the chain conveyor unit 22 is obliquely arranged on the back of the frame 1, and is used to transport the steel rings to be processed delivered by the belt conveyor unit 21 one by one to There are 3 turntable mechanisms. In this structure, the belt conveying unit 21 is an existing technology, which is used to receive the steel rings conveyed from the previous station, and then transfer them to the chain conveying unit 22, and the chain conveying unit 22 sequentially conveys the steel rings to the turntable mechanism one by one 3. The transmission process is relatively stable.

[0050] The chai...

Embodiment 3

[0051] Embodiment 3: As shown in the figure, other structures are the same as Embodiment 2. The difference is that the turntable mechanism 3 includes a mounting base 31, a first motor 32 and a rotating disk 33, and the mounting base 31 is fixed on the front of the frame 1. part, and the top of the mounting seat 31 has a fixed plate 34 inclined downwards, the rotating disk 33 is rotatably arranged on the upper end of the fixed plate 34, and the upper surface of the rotating disk 33 is provided with an accommodating chamber 35 for placing the steel ring, The first motor 32 is fixed in the mounting seat 31, and is used to drive the rotating disc 33 to rotate. The mobile frame 4 is composed of two side plates 41 and a top plate 42 fixed between the two side plates 41. The two side plates 41 are respectively The first cylinder 43 can move back and forth and is arranged on the left and right sides of the installation seat 31 , and a first guide assembly 44 is arranged between each si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com