A spoon dyeing device

A dyeing device and spoon technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of inability to uniformly control the dyeing time, time-consuming and labor-intensive problems, and achieve the effect of reducing manual operations and facilitating collection and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

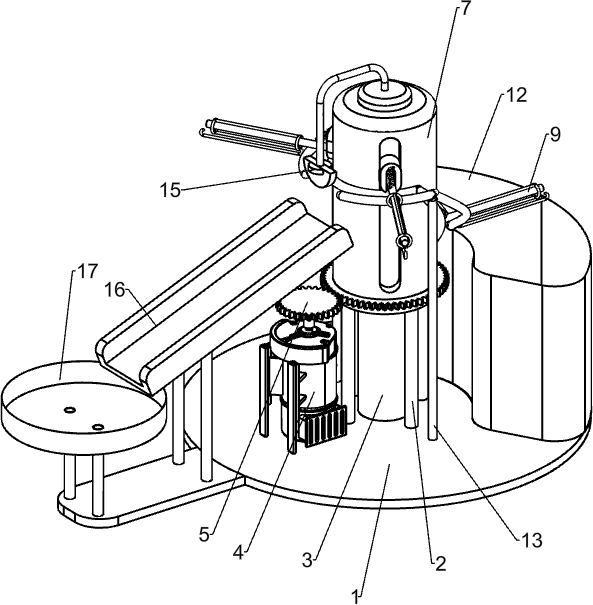

[0020] A spoon dyeing device, such as Figure 1-3 As shown, including the rack 1, the support frame 2, the cylindrical 3, the dye box 12, the power assembly, and the support assembly, the upper intermediate welding of the frame 1 is welded, and the cylindrical 3 is located in the support frame 2, the rack 1 The upper right side is placed with a dye box 12, and the upper portion of the rack 1 is provided with a power assembly that operates by the motor rotation, and the power assembly is slidably disposed.

[0021] like figure 1 with 2 As shown, the power assembly includes a reduction motor 4, a gear 5, a ring gear 6, and a rotating sleeve 7, and the upper left side of the rack 1 passes through the bolt, and the output shaft of the reduction motor 4 is connected by the rotor. The gear 5, the upper rotation of the support frame 2 is provided with a rotating sleeve 7, and the cylindrical 3 is located in the rotary sleeve 7, and the rotary sleeve 7 is connected to the ring gear 6, and ...

Embodiment 2

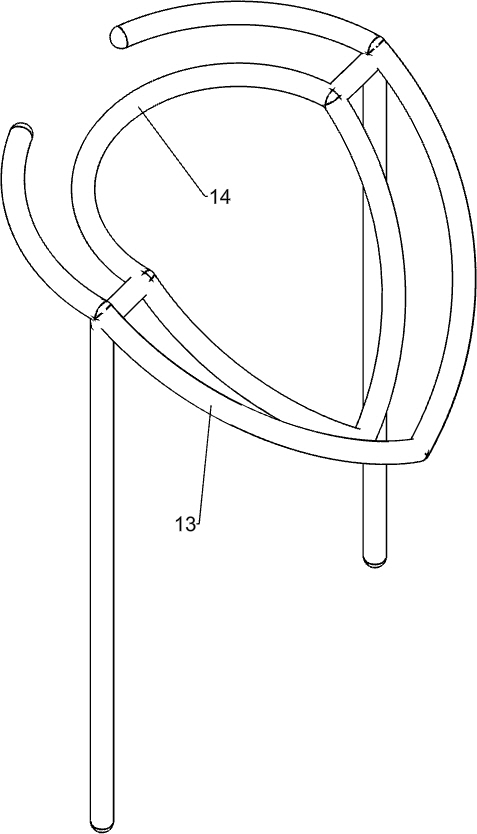

[0027] On the basis of Example 1, if figure 1 with 4 As shown, there is also included a first adjustment lever 13 and a second adjustment lever 14, and a first adjustment lever 13 is welded at the top of the frame 1, and the second adjustment lever 13 is welded in the first regulating lever 13.

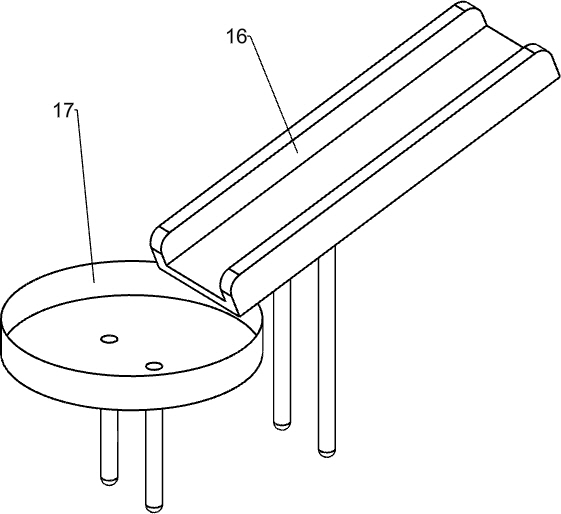

[0028] like figure 1 with 5 As shown, there is also a stopper 15, a slide 16, and a collection box 17. The left side of the top of the cylindrical 3 is welded, and the left side of the rack 1 has a slide 16, and the left side of the rack 1 is welded to the collected box 17. .

[0029] The working principle of the above embodiment: When the support assembly is moved, the slider 8 is in line with the second regulating lever 14, and as the second adjustment lever 14 is lifted down, the pendulum rod 9 drives the spoon from the dye box 12 Dye box 12, and exit from above after dyeing, preventing dye from moving out along the side wall of the dye box 12. In this process, the pendulum 9 is tightl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com