Automatic animal fur carding equipment

A technology for animal fur and equipment, applied in the field of automatic animal fur carding equipment, can solve the problems of repeated carding, low carding process efficiency, time-consuming and labor-intensive manual operation, etc., to achieve the effect of improving automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

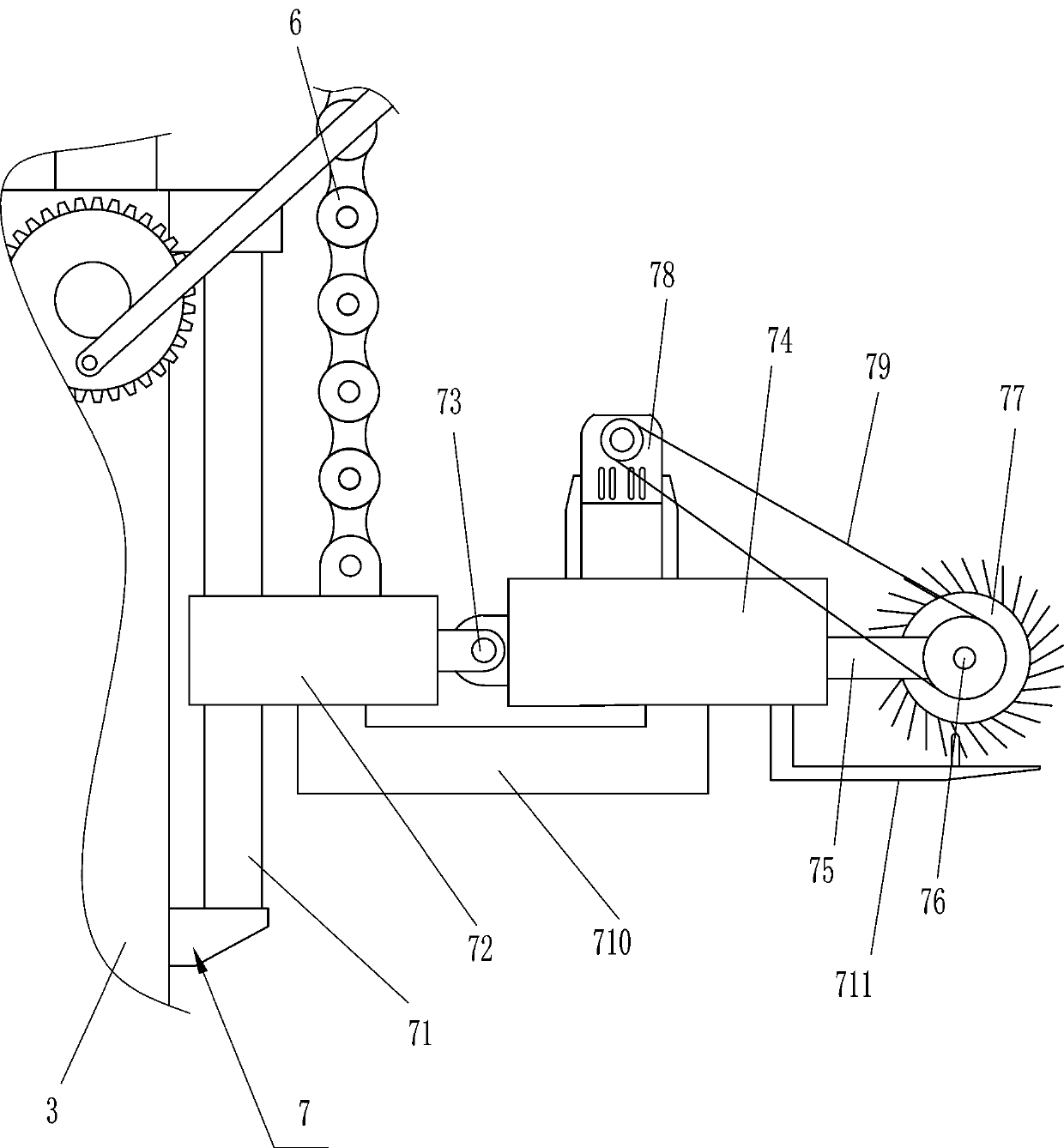

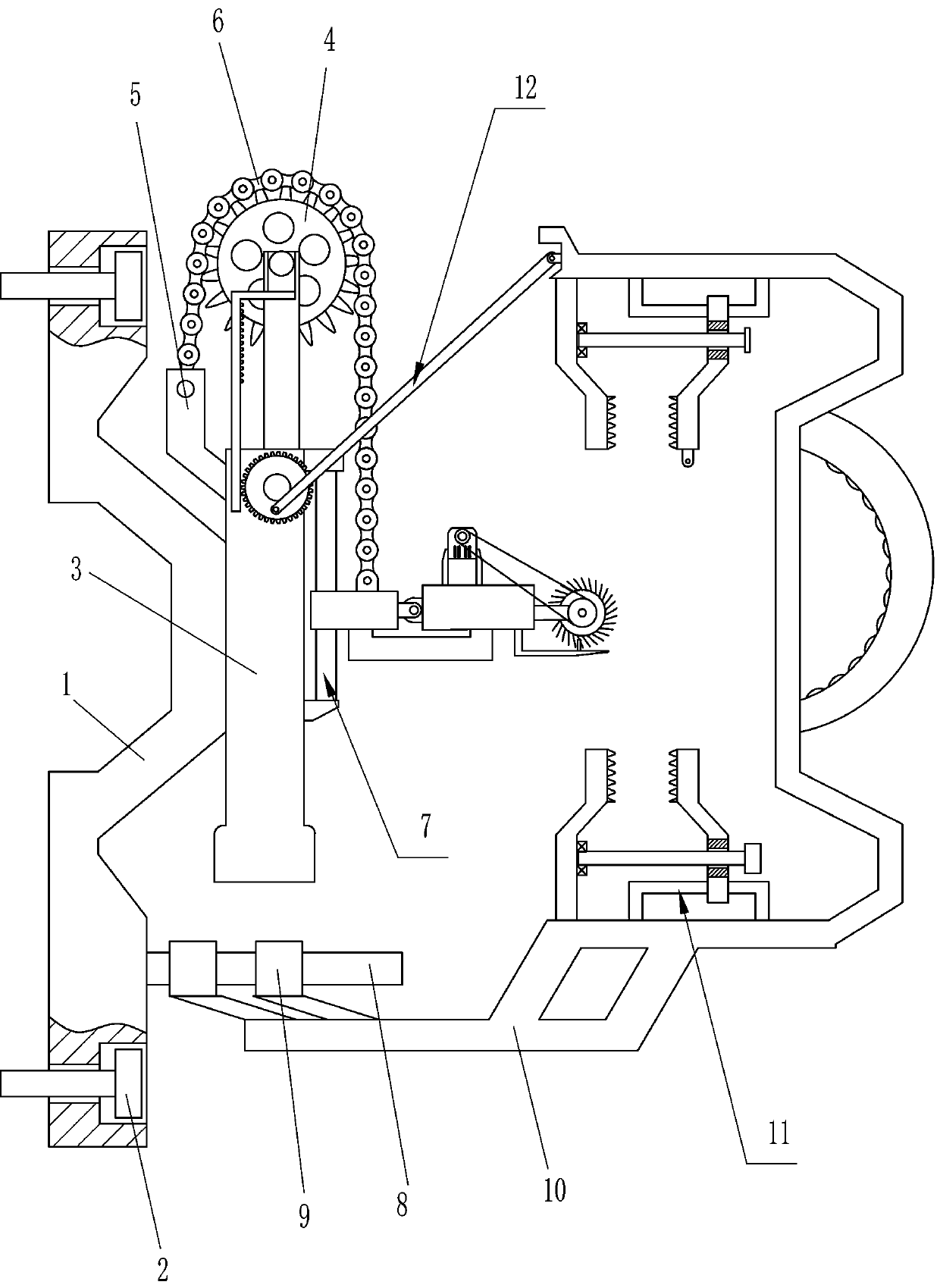

[0018] A kind of automatic animal fur grooming equipment, such as figure 1 As shown, it includes a wall hanging frame 1, an expansion screw 2, an electric push rod 3, a sprocket 4, a first fixed block 5, a chain 6, a brush device 7, a first guide rail 8, a first guide sleeve 9, a moving frame 10 and Clamping device 11, specifically:

[0019] Two sets of expansion screws 2 are arranged on the upper and lower sides of the wall hanging frame 1, and the right side of the wall hanging frame 1 is connected with an electric push rod 3, and the telescopic rod of the electric push rod 3 is rotatably connected with a sprocket 4. The upper left side of the electric push rod 3 is connected with a first fixed block 5, the sprocket 4 is wound with a chain 6, and one end of the chain 6 is connected to the first fixed block 5, and the right side of the electric push rod 3 A bristle device 7 is provided, the other end of the chain 6 is connected to the bristle device 7, a first guide rail 8 i...

Embodiment 2

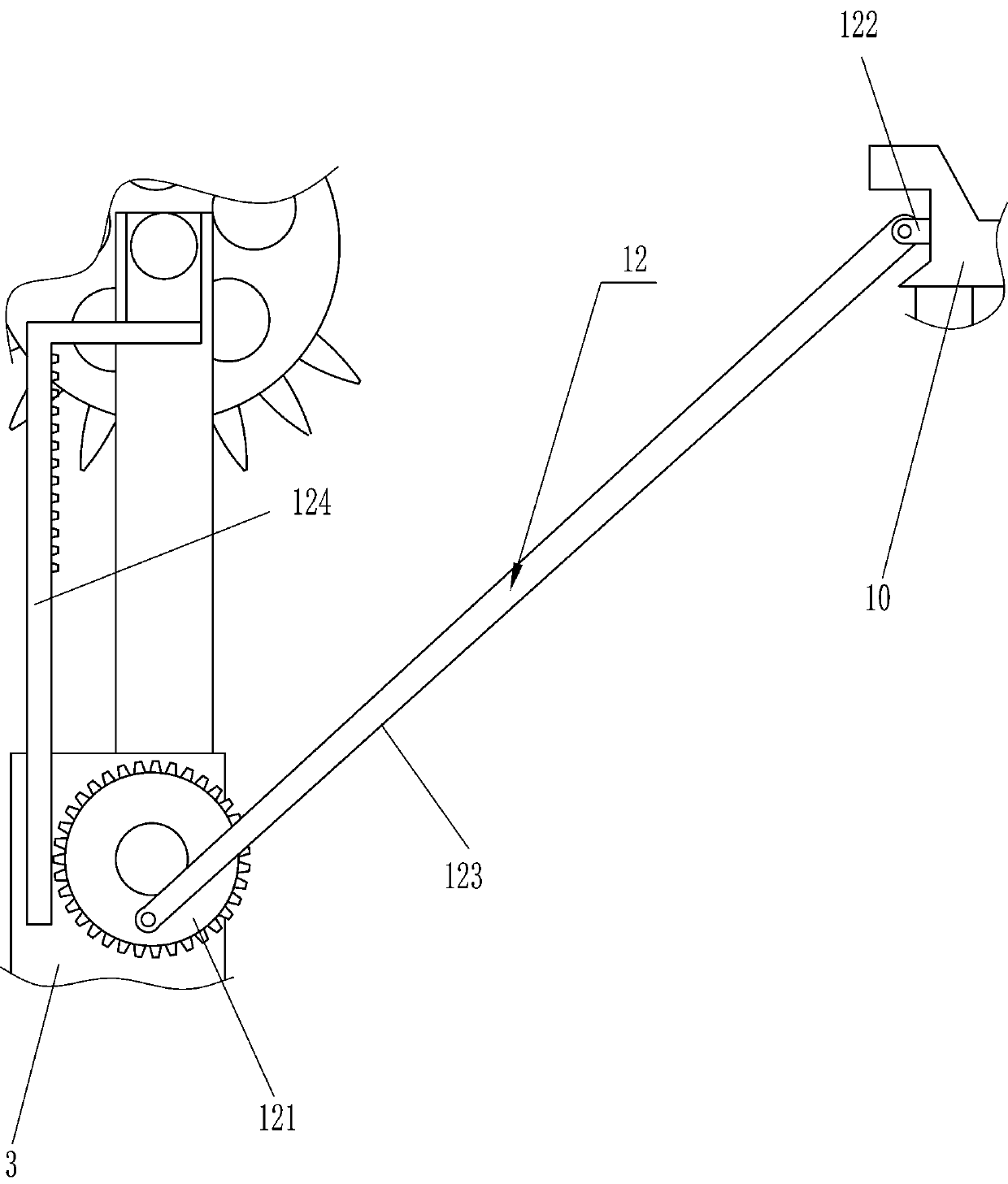

[0028] On the basis of Example 1, such as Figure 4 As shown, a pushing device 12 is also included, and the pushing device 12 includes a gear 121, a second connecting block 122, a moving rod 123 and a rack 124, specifically:

[0029]The front side of the electric push rod 3 is rotatably connected with a gear 121, and the left side of the upper wall of the moving frame 10 is connected with a second connecting block 122, and the eccentric position of the front side of the gear 121 is connected with the second connecting block 122. A moving rod 123, the two sides of the moving rod 123 are rotationally connected to the gear 121 and the second connecting block 122, and a rack 124 is connected to the upper front side of the telescopic rod of the electric push rod 3, and the rack 124 Mesh with the gear 121.

[0030] When the fur is clamped by the clamping device 11, the electric push rod 3 can be started directly, and the upward movement of the telescopic rod of the electric push ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com