Flame-retardant wiring plastic pipe for preventing ignition caused by short circuit of circuit

A technology of plastic pipes and circuits, applied in the direction of circuits, conductive connections, connections, etc., can solve the problems of not being able to cut off and isolate automatically, and not be able to automatically extinguish fires, and achieve the effect of reducing losses and preventing safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

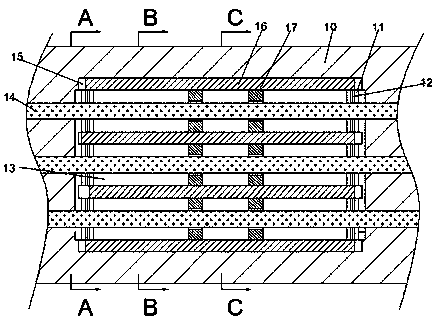

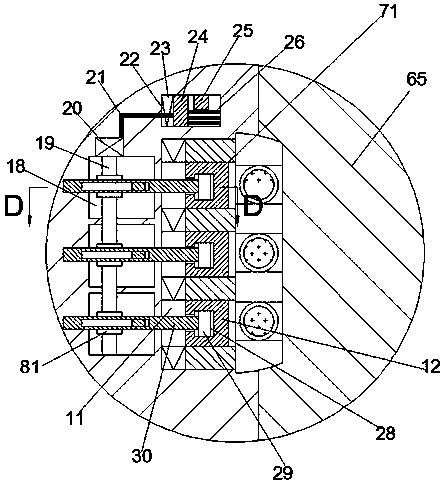

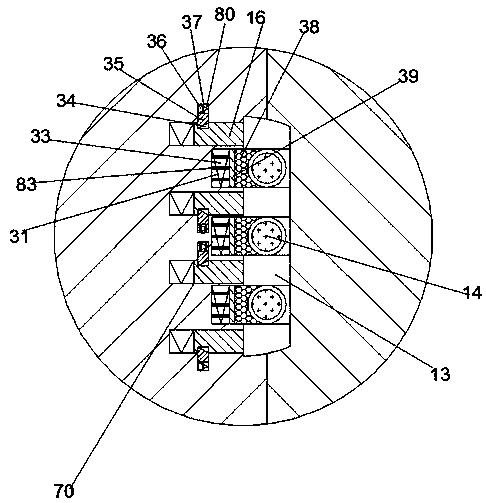

[0019] Combine below Figure 1-6 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0020] combined with Figure 1-6 The flame-retardant wiring plastic tube for preventing circuit short circuit from igniting includes a box body 10 and a box cover 65, the box body 10 is provided with a wiring chamber 13, and the wiring chamber 13 is provided with a wire in the plastic pipe. A cut-off mechanism 70 for isolating lines. The left and right ends of the wiring cavity 13 are provided with a cutting power-off mechanism 71 that cuts off the short-circuited and ignited lines. An efficient fire extinguishing mechanism 72 for fire extinguishing, the partition mechanism 70 includes two fixed brackets 17 fixed on the rear cavity wall of the wiring cavity 13, and the two fixed brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com