Firing type cleaning and maintaining equipment for railway track slag

A technology for railway track and maintenance equipment, which is applied in the direction of track, lighting and heating equipment, roads, etc. It can solve the problems of inability to screen and clean, affect railway safety, and high labor intensity, so as to protect the overall integrity and the safety of sleepers , the effect of protecting the movement route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

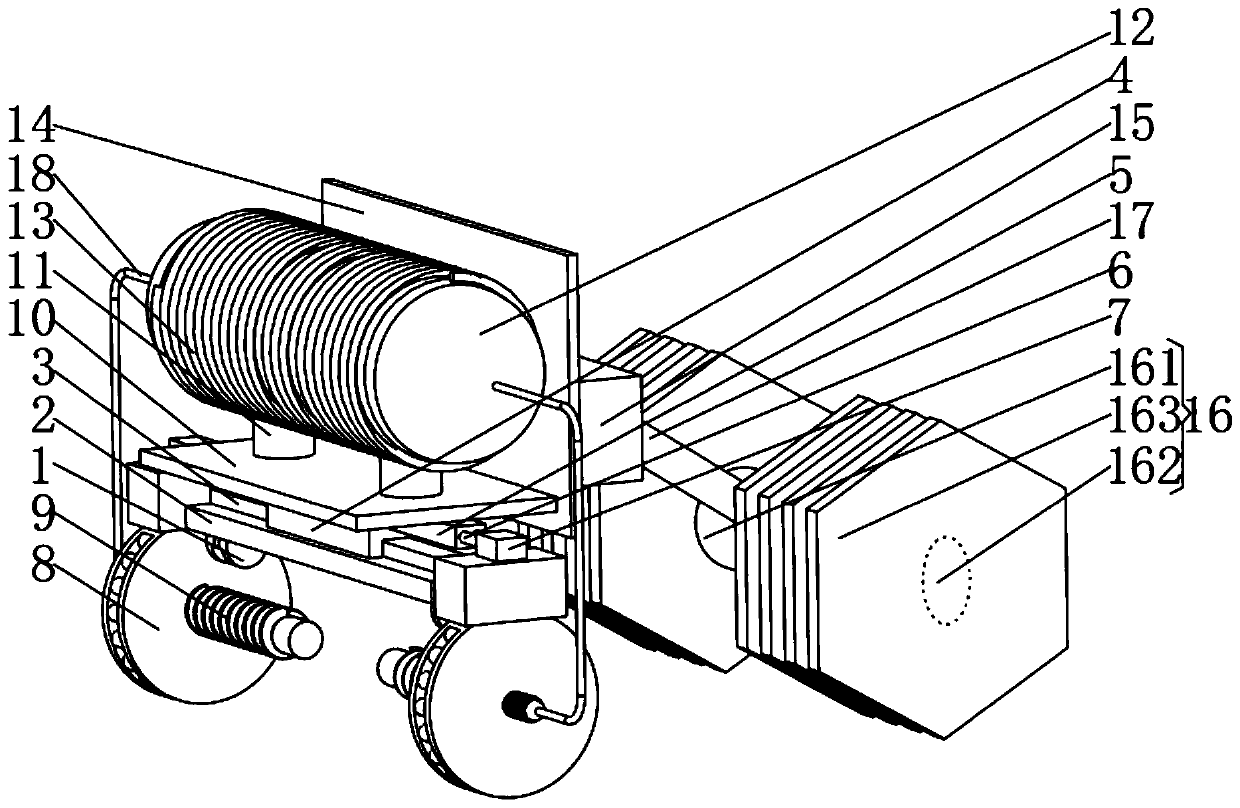

[0035] see Figure 1-2, the present invention provides a technical solution: a railway track ballast burning type cleaning and maintenance equipment, including a positioning limiting wheel 1, the top of the positioning limiting wheel 1 is fixedly connected with a fireproof heat shield 2, and the fireproof heat shield 2 is far away from the positioning limit The middle position of one side of the wheel 1 is fixedly connected with a permanent magnet track 3, and the side of the permanent magnet track 3 away from the fireproof heat shield 2 is slidably connected with an electromagnetic sliding sleeve 4, and the side of the electromagnetic sliding sleeve 4 away from the permanent magnet track 3 is fixedly connected There is a pneumatic telescopic cylinder 5, and the middle position of the outer wall on both sides of the pneumatic telescopic cylinder 5 is slidingly connected with a telescopic column 6, and the end of the telescopic column 6 away from the pneumatic telescopic cylinde...

Embodiment 2

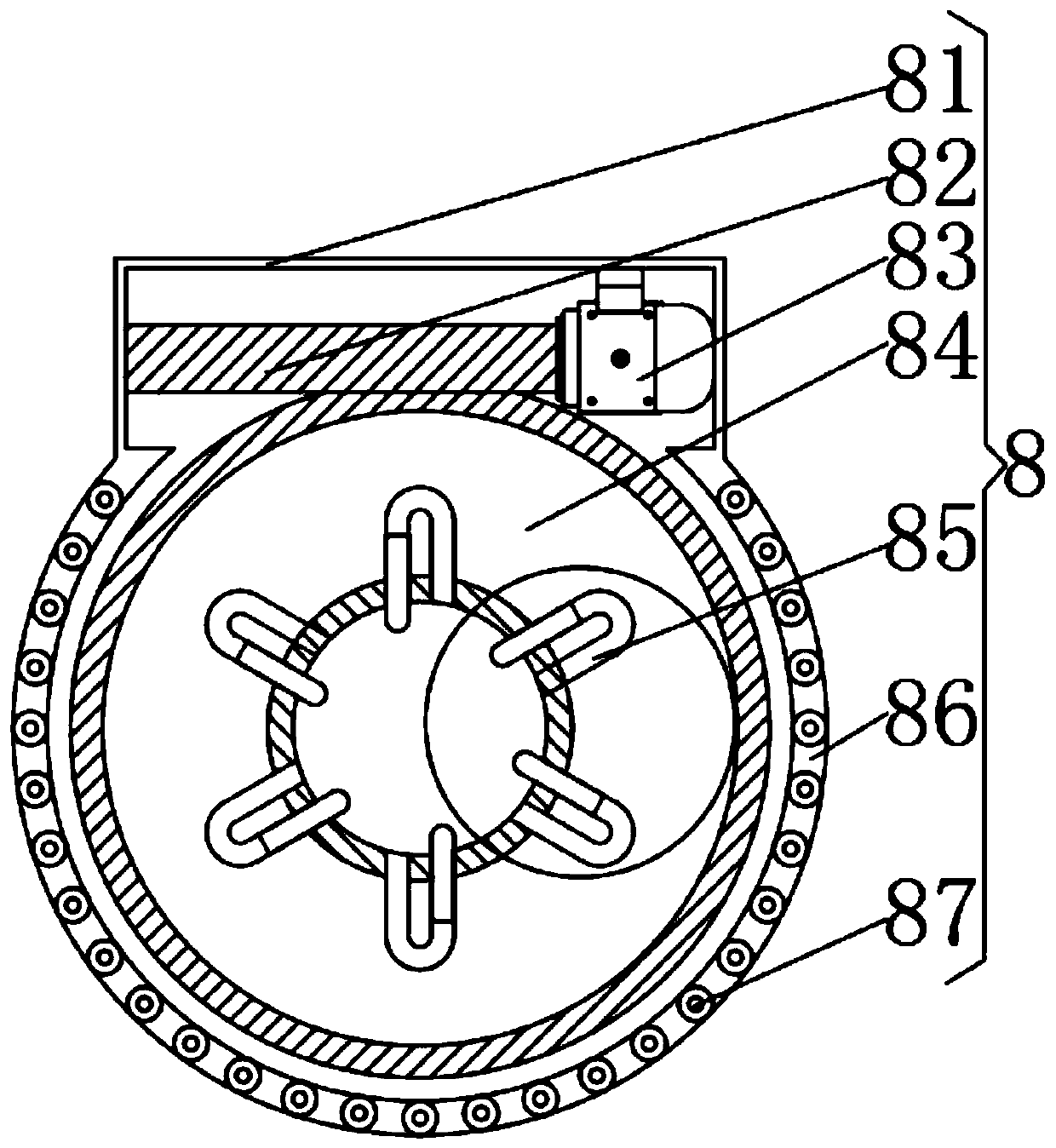

[0037] see Figure 1-4 , the present invention provides a technical solution: on the basis of Embodiment 1, the adjustment mechanism 8 includes an adjustment outer frame 81, an adjustment worm 82 is arranged at the middle position of the inner wall on both sides of the top of the inner cavity of the adjustment outer frame 81, and the right end of the adjustment worm 82 passes through the joint. The shaft is fixedly connected with an adjusting motor 83, the bottom of the outer surface of the adjusting worm 82 is engaged with an adjusting worm gear 84, the inner surface of the adjusting worm gear 84 is provided with a limiting mechanism 85, the outer surface of the adjusting outer frame 81 is provided with a groove 86, and the inner surface of the groove 86 Training wheels 87 are provided. The limiting mechanism 85 includes a positioning hole groove 851, the inner surface of the positioning hole groove 851 is slidably connected with a limiting bolt 852, and the end of the positi...

Embodiment 3

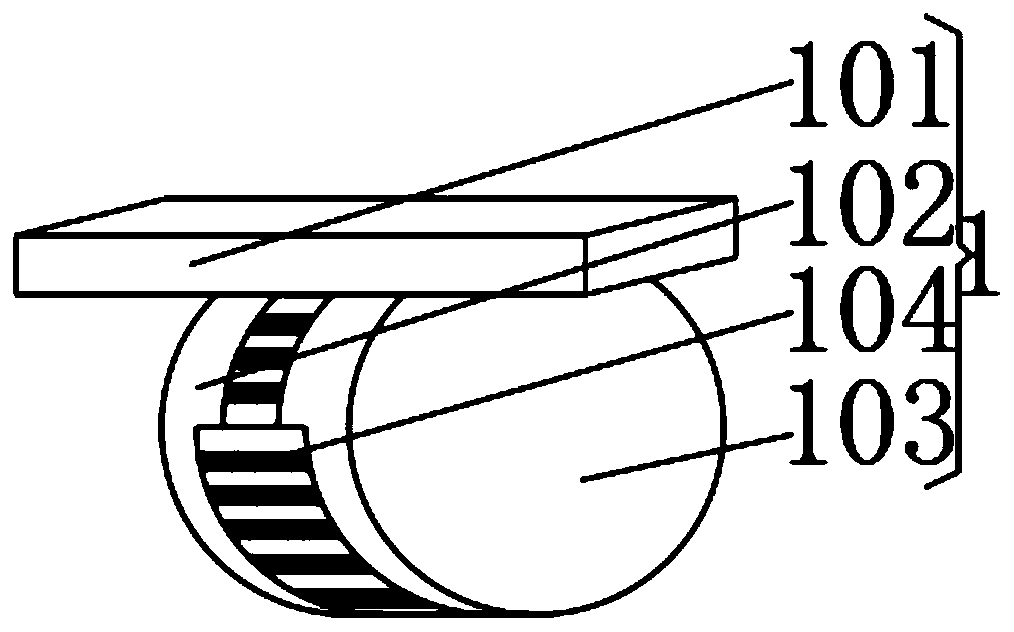

[0039] see Figure 1-6 , the present invention provides a technical solution: on the basis of Embodiment 1 and Embodiment 2, the burning cleaning mechanism 9 includes a main shaft 91, a fuel through hole 92 is opened in the middle of the main shaft 91, and the sides of the outer surfaces of the main shaft 91 are close to each other A push screw 93 is provided, an igniter 94 is fixedly connected to one end of the main shaft 91 close to each other, an adjusting thread 95 is provided on the outer surface of the main shaft 91 close to the adjusting mechanism 8, and a limiting hole is arranged on the outer surface of the main shaft 91 between the adjusting thread 95 96 , the bottom of the limiting hole 96 communicates with the fuel through hole 92 , and the fuel through hole 92 is located on one side of the full push screw 93 and extends to the outer surface. The protection mechanism 11 includes a base 111 , a spring post 112 is fixedly connected to the middle of the top of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com